Anti-freezing concrete and preparation method thereof

A concrete and antifreeze technology, applied in the field of concrete, can solve the problems of concrete impermeability and compactness, concrete freeze-thaw resistance, concrete damage freeze-thaw damage, etc., to provide freeze-thaw resistance and improve freeze-thaw resistance melt performance, improve the effect of crack resistance and erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

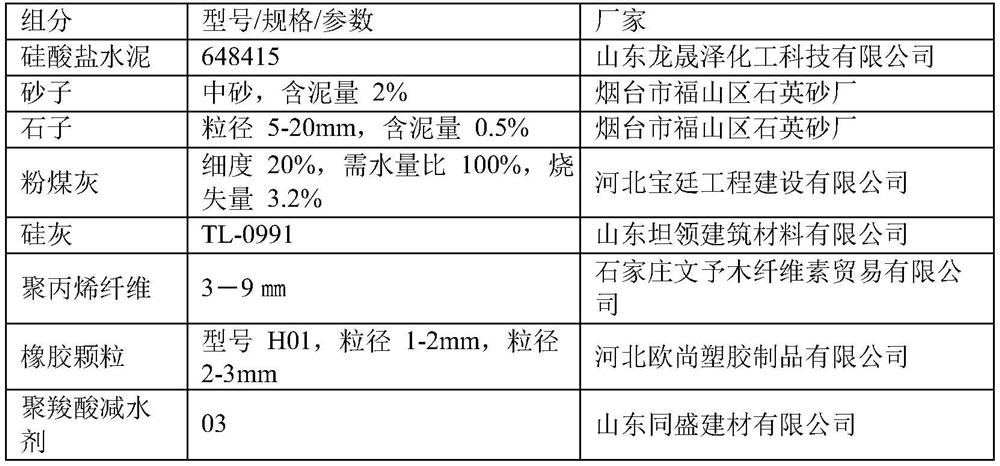

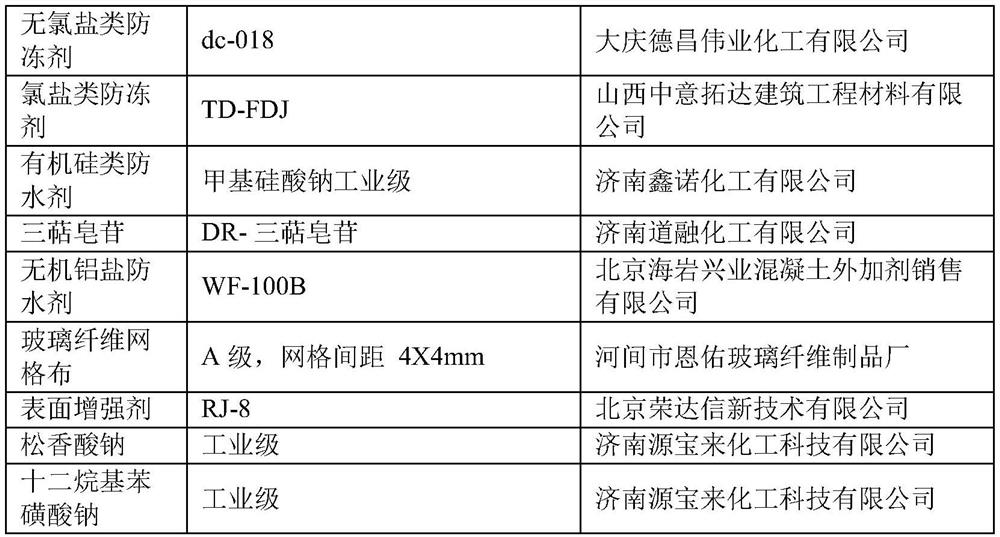

Method used

Image

Examples

Embodiment 1

[0042] A kind of antifreeze concrete, adopts following method to make:

[0043] S1: Weigh 30kg of Portland cement, 13kg of filler, 3kg of anti-crack fiber and 8kg of rubber particles into the mixer, mix and stir at a speed of 300r / min for 1min, then add 32kg of sand, 46kg of stones and 15kg of water, and continue to stir rapidly 4min. The filler is a mixture of fly ash and silica fume with a mass ratio of 1:1, the anti-crack fiber is polypropylene fiber, the particle size of rubber particles is 1-2mm, and the sand is fine sand with a fineness modulus of 1.6-2.2. The particle size of the stones is 5-8mm.

[0044] S2: Continue to add 0.8kg of water reducing agent, 0.5kg of antifreeze, 0.1kg of air-entraining agent and 0.3kg of waterproofing agent into the mixer, and stir for 1 minute to obtain a concrete pouring material. The speed of the mixer is 300r / min to obtain a concrete pouring material. The water reducer is polycarboxylate water reducer, the antifreeze is chlorine-free...

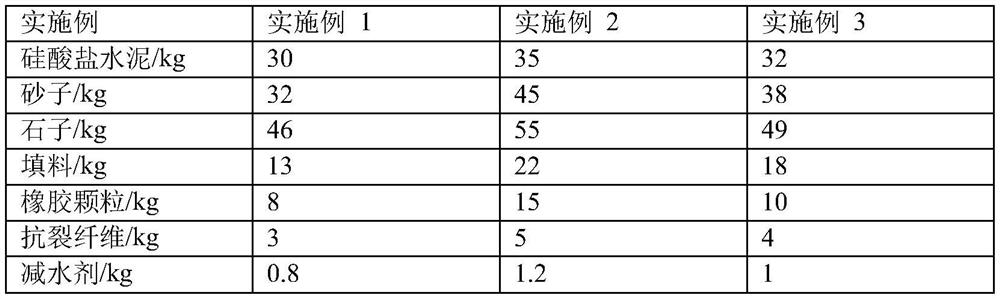

Embodiment 2

[0048] A kind of frost-resistant concrete, the difference from Example 1 is that the ratio of raw materials is different, and the ratio of raw materials of each component is shown in Table 2.

[0049] Table 2

[0050]

[0051]

Embodiment 3

[0053]A kind of frost-resistant concrete, the difference from Example 1 is that the ratio of raw materials is different, and the ratio of raw materials of each component is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com