Processing method of slate glass

A processing method and glass technology, applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of heavy real rock slabs, uncustomizable patterns, symbols, and windows that cannot be hollowed out, so as to reduce deviation and Cascading issues, superior performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

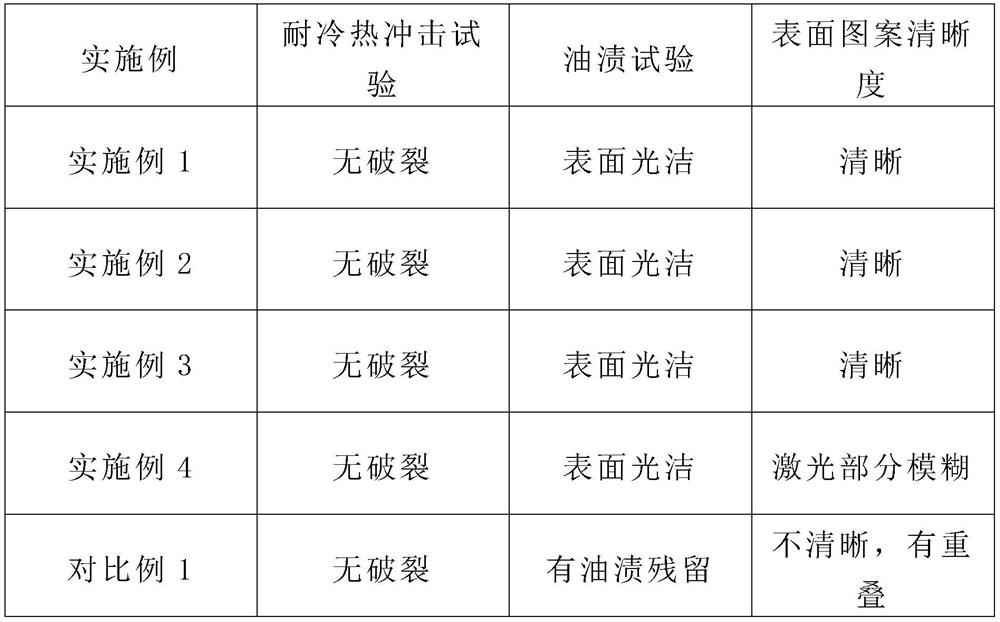

Examples

Embodiment 1

[0029] Scribe the original glass first, and then grind the edge to get a semi-finished glass with a thickness of 8mm. Then spray the first black primer and the second white primer on the front of the glass. The drying temperature of the primer is 170°C, and the speed is 0.9m / s, then use high-temperature ink to print custom patterns on the front of the glass, and then dry them. The drying temperature is 170°C, the speed is 0.9m / s, and then laser engraving is carried out on the reverse side of the glass. The laser engraving power is 70%, and the speed is 1800mm / s. Finally, the finished slate glass is tempered. The tempering process is as follows: The heating time is 200s, the heating time is 200s, the tempering wind pressure is 50%, the cooling wind pressure is 80%, the tempering time is 60s, and the cooling time is 140s.

Embodiment 2

[0031] First scribing the original film and then edging to obtain a semi-finished slate glass with a thickness of 4mm. Then, the first black window screen screen printing is carried out on the front of the glass. The first white window hollow mesh silk screen printing, the mesh silk screen printing mesh number is 250, and finally the third window hollow white texture mesh silk screen printing on the front of the glass, the mesh silk screen printing mesh number is 250, each screen printing is dried, dried The temperature is 200°C, and the line speed is 5m / min. Then use high-temperature ink to print customized patterns on the front of the glass (avoid the hollow window), and then dry them at a temperature of 170°C and a speed of 0.9m / s. Finally, laser engrave symbols and lines on the back of the glass. The power is 65%, the speed is 1600mm / s, and finally tempered to obtain the finished slate glass. The tempering process is as follows: preheating time 70s, heating time 70s, tempe...

Embodiment 3

[0033] Scribe the original glass first, then grind the edge to get a semi-finished slate glass with a thickness of 10mm, then sand the front of the glass with 36 mesh emery at a speed of 4m / min, then clean it, and then spray the front of the glass with a white background The glaze and bottom glaze are dried at a temperature of 170°C and a speed of 0.8m / s, and then the front of the glass is printed with a custom pattern using high-temperature ink, and then dried at a temperature of 170°C and a speed of 0.8m / s, and finally tempered The tempering treatment of the finished slate glass is as follows: preheating time 260s, heating time 250s, tempering wind pressure 40%, cooling wind pressure 80%, tempering time 65s, cooling time 200s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com