Bottle blank structure beneficial to stretch blow molding

A technology of stretch blow molding and preform, which is applied in the field of preform structure that is conducive to stretch blow molding. It can solve the problems of premature cooling of materials, cracking of the bottom, and excessive thickness of the center point, so as to avoid serious accumulation of material at the bottom of the bottle. , Avoid too thick, reduce the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

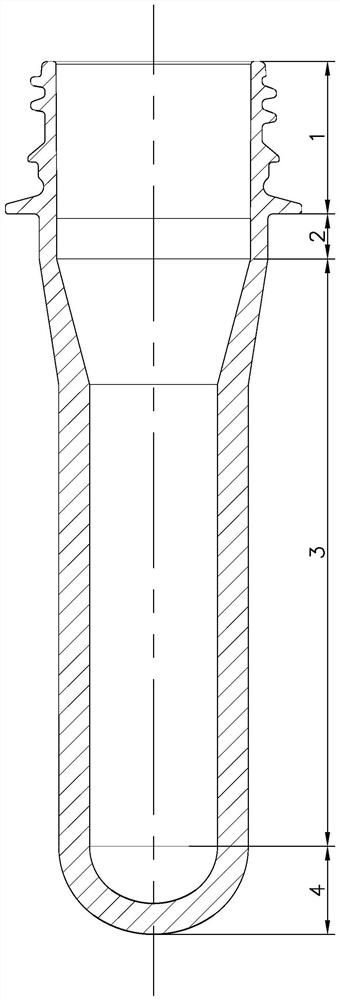

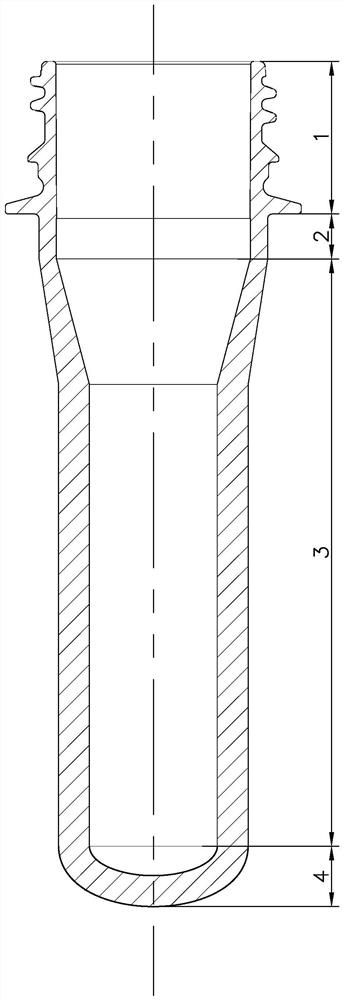

[0028] like Figure 1 to Figure 7 As shown, this embodiment discloses a preform structure that is beneficial to stretch blow molding, including an integrally injection-molded preform, and the preform includes a bottle mouth (1), a bottle neck (2), and a preform ( 3) and the bottom of the blank (4), the axial length of the neck (2) is preferably 5-6mm. Since the bottle blank is used for bottle blow molding, the neck (2) is used as the pinch when blowing the bottle. For standard thickness As far as the wall thickness of the bottleneck (2) is about 4-4.5mm, if the axial length of the bottleneck (2) is less than 5mm, it is easy to cause the problem of pinching the preform, if the axial length of the bottleneck (2) is greater than 6mm , because the bottleneck (2) does not participate in stretching during bottle blowing, it will cause too much material waste, and at the same time, the bottleneck transition part (31) that is blown out is prone to material accumulation, which affects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com