Positive electrode composite material for lithium primary battery and preparation method thereof

A composite material and positive electrode technology, applied in the field of positive electrode composite materials for lithium primary batteries and their preparation, can solve the problems of poor battery rate performance, voltage hysteresis of fluorocarbon batteries, weak electrical conductivity, etc., and achieve outstanding substantive characteristics, The effect of good discharge rate performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

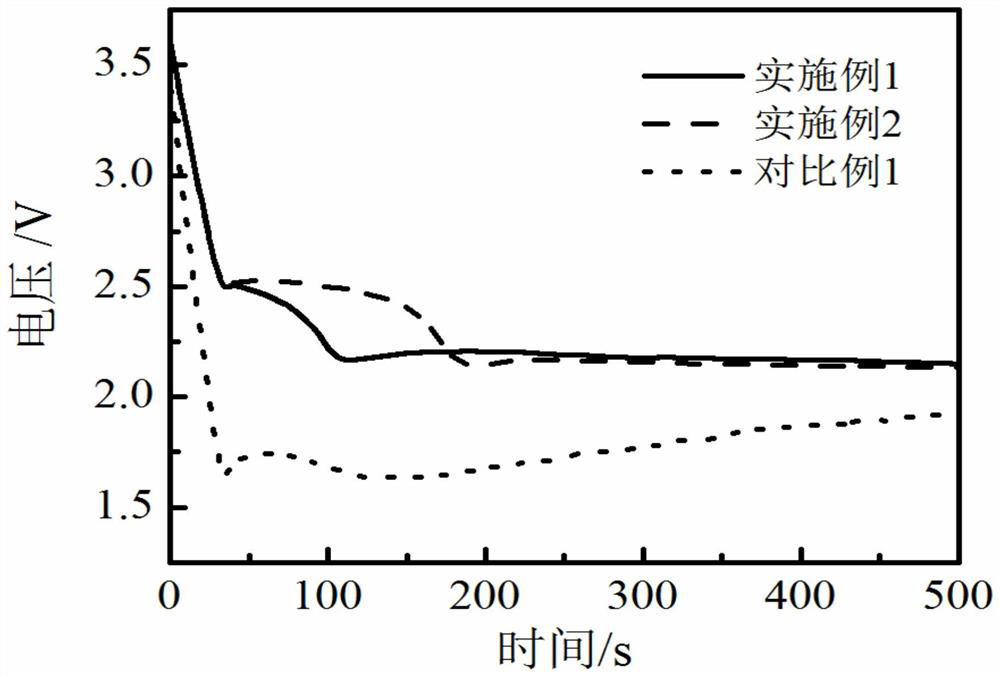

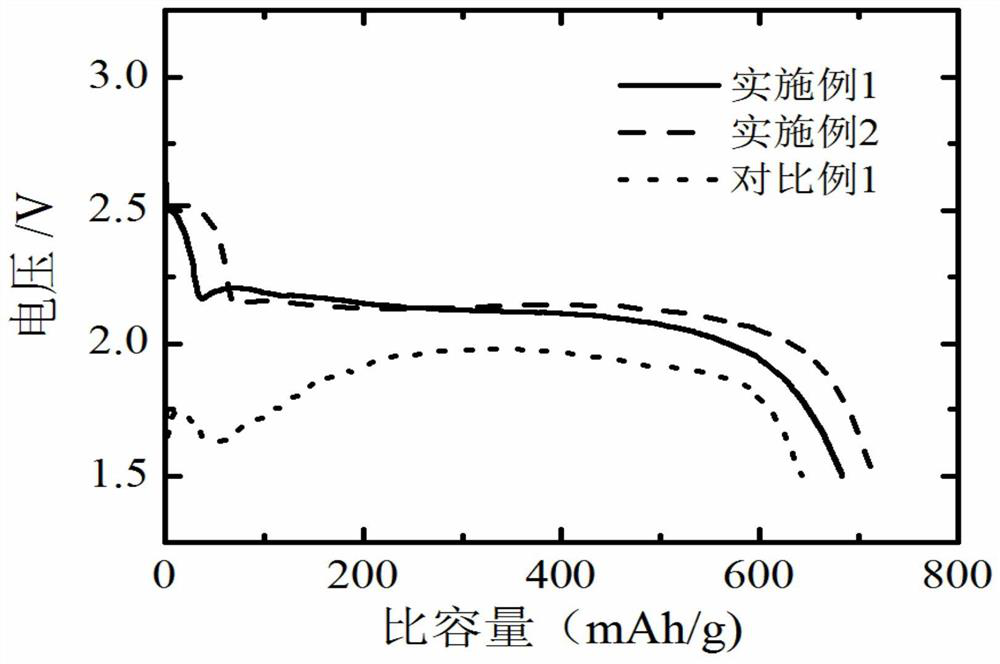

Embodiment 1

[0032] Put the pre-treated graphite powder 10.0g into the reactor, access NF 3 Volume score 100% NF 3 Gas, keep NF 3 The pressure is 100 kPa, the reactor is heated and the reaction temperature is maintained at 400 ° C, and the reaction is 8 h. The reactor was naturally cooled to remove the product, which was treated in vacuo at 200 ° C for 6 hours to give fluorinated graphite.

[0033] Put the pre-treated Cosa black powder 5.0g into the reactor, access NF 3 Volume score 100% NF 3 Gas, keep NF 3The pressure was 100 kPa, heated the reactor and maintaining the reaction temperature at 500 ° C, and the reaction was 8 hours. After the reactor was naturally cooled, the product was taken out and treated in vacuo at 200 ° C for 6 hours to give fluoride black.

[0034] The resulting fluorinated graphite and the fluorinated core were placed in a ball mill according to the mass ratio of 1: 0.01, and the ball milling speed was 50 rpm, ball milling 48h, resulting in a positive electrode composi...

Embodiment 2

[0036] Put the pre-treated graphite powder 10.0g into the reactor, access NF 3 NF of 90% volume fraction 3 Gas, keep NF 3 The pressure was 120 kPa, the reactor and the reaction temperature were maintained at 500 ° C, and the reaction was 10 h. The reactor was naturally cooled to remove the product, which was treated in vacuo at 200 ° C for 6 hours to give fluorinated graphite.

[0037] Put the pre-treated Cosa black powder 5.0g into the reactor, access NF 3 Volume score 100% NF 3 Gas, keep NF 3 The pressure was 120 kPa, heated the reactor and maintaining the reaction temperature at 400 ° C, and the reaction was 8 h. After the reactor was naturally cooled, the product was taken out and treated in vacuo at 200 ° C for 6 hours to give fluoride black.

[0038] The resulting fluorinated graphite and fluorinated core were placed in a ball mill according to the mass ratio of 1: 0.1, and the ball milling speed was 120 rpm, ball milling 12h, gave a positive electrode composite.

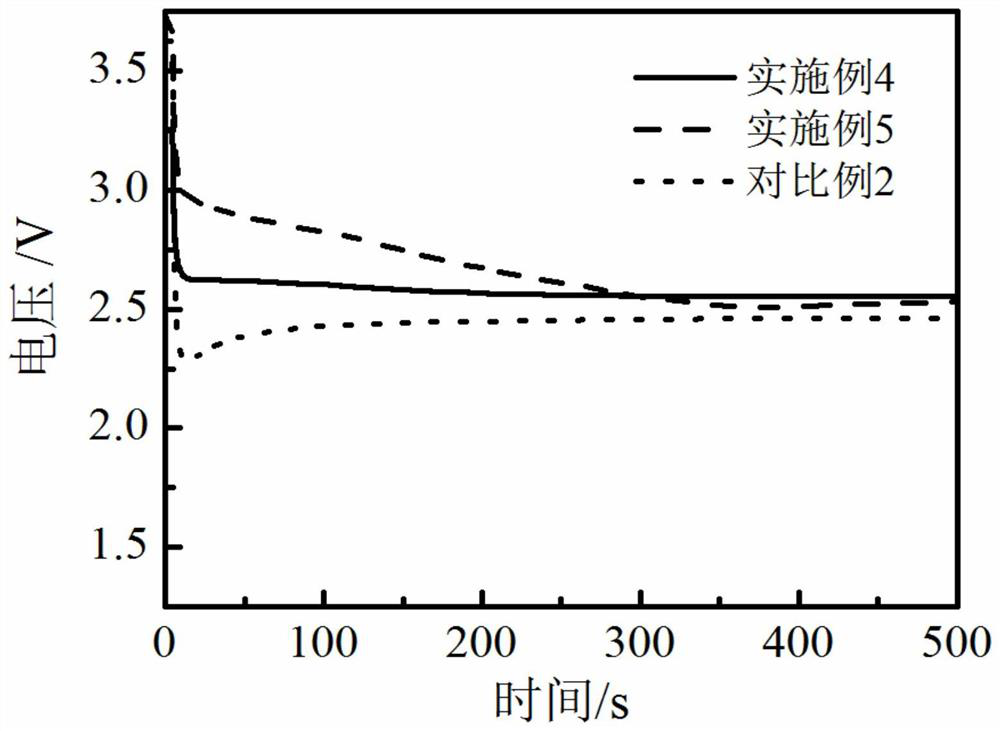

Embodiment 3

[0040] Put 10.0g of the preprocessed mesh carbon powder into the reactor, access NF 3 Summer score of 60% NF 3 Gas, keep NF 3 The pressure was 200 kPa, heated the reactor and maintaining the reaction temperature at 600 ° C, and the reaction was 12 h. The reactor was naturally cooled to remove the product, which was treated with a vacuum treatment at 200 ° C for 6 hours to obtain a fluorinated mesoporous carbon.

[0041] Put the pre-treated Cosa black powder 5.0g into the reactor, access NF 3 Volume score 100% NF 3 Gas, keep NF 3 The pressure was at 300 kPa, the reactor was heated and the reaction temperature was maintained at 450 ° C, and the reaction was 12 h. After the reactor was naturally cooled, the product was taken out and treated in vacuo at 200 ° C for 6 hours to give fluoride black.

[0042] The resulting fluorinated mesoporous carbon with fluorinated core is placed in a ball mill according to the mass ratio of 1: 0.3, and the ball milling speed is 400 rpm, ball milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com