Atomization combustion method for biomass gas-dissolved pyrolysis oil

A combustion method and pyrolysis oil technology, applied in the direction of combustion methods, burners, lighting and heating equipment, etc., can solve the problems of atomization effect affecting combustion effect, easy flameout, insufficient combustion, etc., to improve the effect of spray atomization , increase the flame temperature, improve the effect of mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

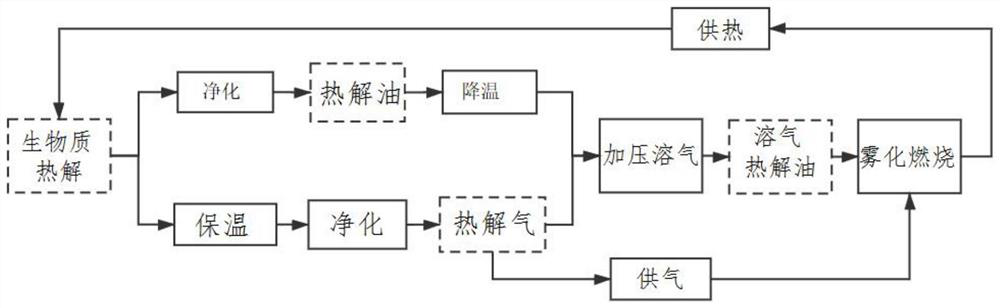

[0044] according to figure 1 As shown in the process flow chart, the pyrolysis gas generated during the biomass pyrolysis process is pretreated, and the pyrolysis gas is kept warm to 65°C through the heat preservation device. After removing the residual carbon particles mixed with the pyrolysis gas, the silica gel desiccant is used Dry the pyrolysis gas to a moisture content of 0.5%;

[0045] according to figure 1 In the process flow chart shown, the pyrolysis oil produced in the biomass pyrolysis process is pretreated. Firstly, the large particle impurity components in the pyrolysis oil are removed so that the particle size of the impurities in the pyrolysis oil is less than 10 μm, and then the pyrolysis oil is left to stand Cool down, the temperature of the pyrolysis oil is reduced to 45°C;

[0046] After the pyrolysis oil and pyrolysis gas are pretreated, the pyrolysis gas is pressurized to 4.2 MPa by an air compressor, and the pyrolysis oil is placed in a pressure dissol...

Embodiment 2

[0051] according to figure 1 As shown in the process flow chart, the pyrolysis gas produced in the biomass pyrolysis process is pretreated, and the pyrolysis gas is kept warm to 80°C through the heat preservation device. After removing the residual carbon particles mixed with the pyrolysis gas, the silica gel desiccant is used. Dry the pyrolysis gas to a moisture content of 0.2%;

[0052] according to figure 1 As shown in the process flow chart, the pyrolysis oil produced in the biomass pyrolysis process is pretreated. Firstly, the large particle impurity components in the pyrolysis oil are removed, and after the particle size of the impurities in the pyrolysis oil is less than 8 μm, the standing Cooling down, the temperature of the pyrolysis oil is reduced to 60°C;

[0053] After pretreatment of the pyrolysis oil and pyrolysis gas, the pyrolysis gas is pressurized to 5MPa by an air compressor, and the pyrolysis oil is placed in a pressure dissolved gas tank. The height of t...

Embodiment 3

[0057] according to figure 1 As shown in the process flow chart, the pyrolysis gas generated during the biomass pyrolysis process is pretreated, and the pyrolysis gas is kept at 70°C by the heat preservation device. After removing the residual carbon particles mixed with the pyrolysis gas, the silica gel desiccant is used Dry the pyrolysis gas to a moisture content of 0.8%;

[0058] according to figure 1 As shown in the process flow chart, the pyrolysis oil produced in the biomass pyrolysis process is pretreated. Firstly, the large particle impurity components in the pyrolysis oil are removed, and after the particle size of the impurities in the pyrolysis oil is <6 μm, the standing Cool down, the temperature of the pyrolysis oil is reduced to 50°C;

[0059] After the pyrolysis oil and pyrolysis gas are pretreated, the pyrolysis gas is pressurized to 4.5MPa by an air compressor, and the pyrolysis oil is placed in a pressure dissolved gas tank. The height of the pyrolysis oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com