High-selectivity lithium extraction electrode and preparation method thereof

A high-selectivity, lithium electrode technology, applied in the direction of process efficiency improvement, coating, surface coating liquid device, etc., can solve the problems of low electrode current density, low lithium selectivity, etc., to improve the extraction rate, Effect of improving selectivity and current density and avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

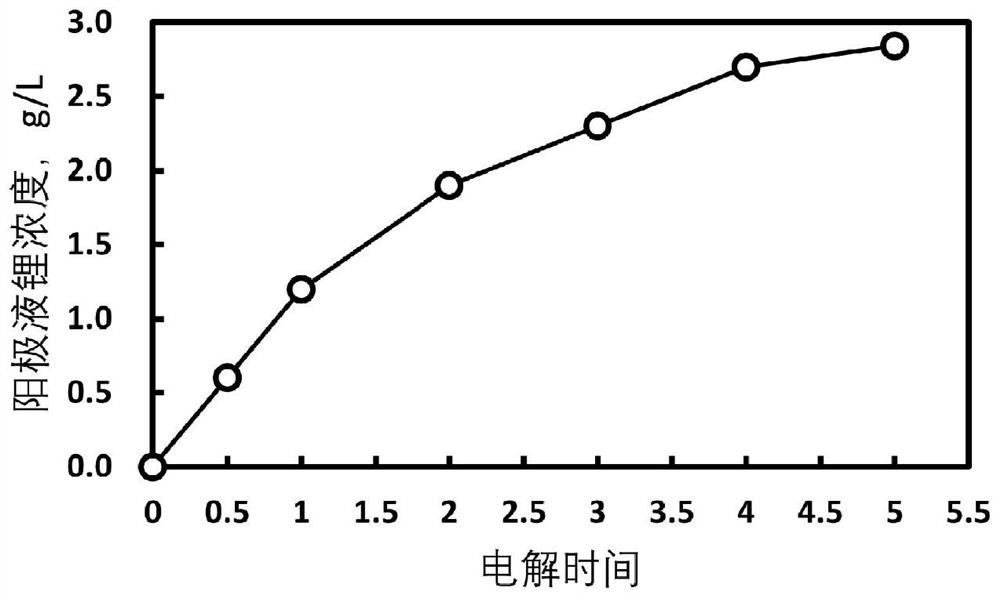

Embodiment 1

[0040] Preparation of lithium iron phosphate electrode: (1) Put the active material of lithium iron phosphate into 5g / L dopamine salt solution according to the solid-liquid mass ratio of 1:5, control the reaction temperature at 20°C, the pH value of the solution at 8.5, and stir for 15 hours. After the reaction is finished, filter and wash, and dry the filter residue at 100°C; (2) add polyethylene glycol and PVDF to N-methylpyrrolidone solvent, and stir until completely dissolved in vacuum; (3) add polydopamine-modified Lithium iron phosphate powder, acetylene black, pore-forming agent solid NaCl, and short carbon fibers with a length of 2mm were added in proportion to the N-methylpyrrolidone glue, and vacuum mechanically stirred for 6 hours to obtain a uniformly dispersed electrode slurry; (4) the obtained The electrode slurry is uniformly coated on a titanium mesh with a thickness of 1mm and an area of 40cm×50cm, and the coating density of the lithium iron phosphate active ...

Embodiment 2

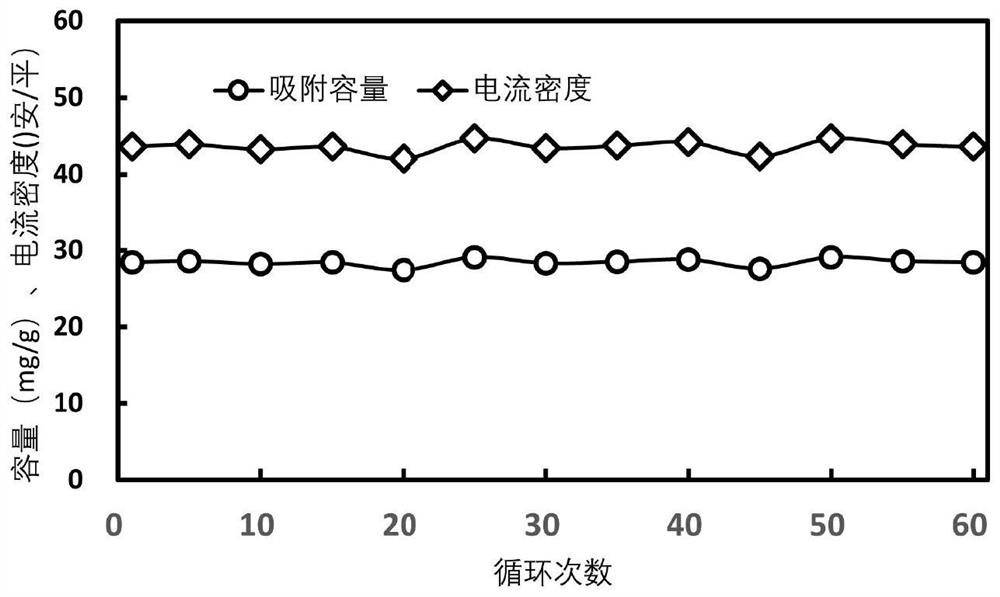

[0054] Preparation of lithium iron phosphate electrode: (1) Put the active material of lithium iron phosphate into 2g / L dopamine salt solution according to the solid-liquid mass ratio of 1:5, control the reaction temperature at 25°C, the pH value of the solution at 9, and stir for 20 hours. After the reaction is finished, filter and wash, and dry the filter residue at 100°C; (2) add polyethylene glycol, chitosan, and PVDF to N-methylpyrrolidone solvent and mechanically stir until completely dissolved; (3) modify polydopamine Lithium iron phosphate powder, conductive agent acetylene black, pore-forming agent solid KCl, and short carbon fibers with a length of 1 mm were added in proportion to the N-methylpyrrolidone glue, and vacuum mechanically stirred for 6 hours to obtain a uniformly dispersed slurry; (4 ) The obtained slurry is evenly coated on a carbon fiber cloth with a thickness of 1 mm and an area of 40 cm × 50 cm, and the coating density of the lithium iron phosphate a...

Embodiment 3

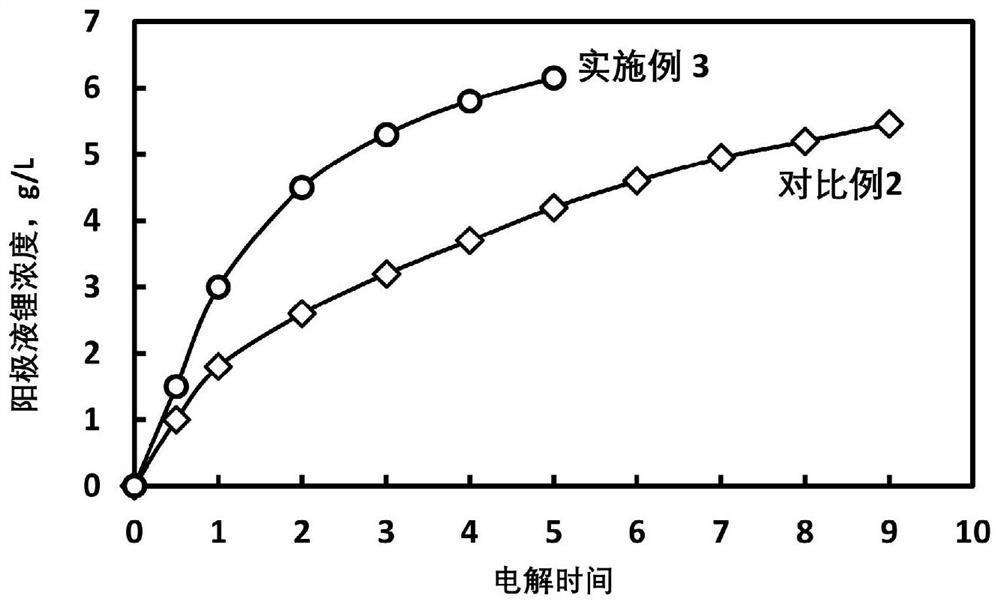

[0058] Preparation of lithium manganate electrode: (1) Put lithium manganate active material into 4g / L dopamine salt solution according to the solid-liquid mass ratio of 1:5, control the reaction temperature at 20°C, the pH value of the solution at 9.5, and stir for 10 hours. After the reaction is finished, filter and wash, and dry the filter residue at 100°C; (2) add polyethylene glycol, polyvinyl alcohol, and PVDF to N-methylpyrrolidone solvent and stir mechanically until they are completely dissolved; (3) modify polydopamine Lithium manganate powder, acetylene black, pore-forming agent solid NaCl, and short carbon fibers with a length of 2.5 mm were added in proportion to the N-methylpyrrolidone glue, and vacuum mechanically stirred for 8 hours to obtain a uniformly dispersed slurry; (4) The obtained slurry is evenly coated on a carbon fiber cloth with a thickness of 1mm and an area of 40cm×50cm, and the coating density of the lithium manganate active material after drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com