Bionic multifunctional ice-resistant surface and preparation method thereof

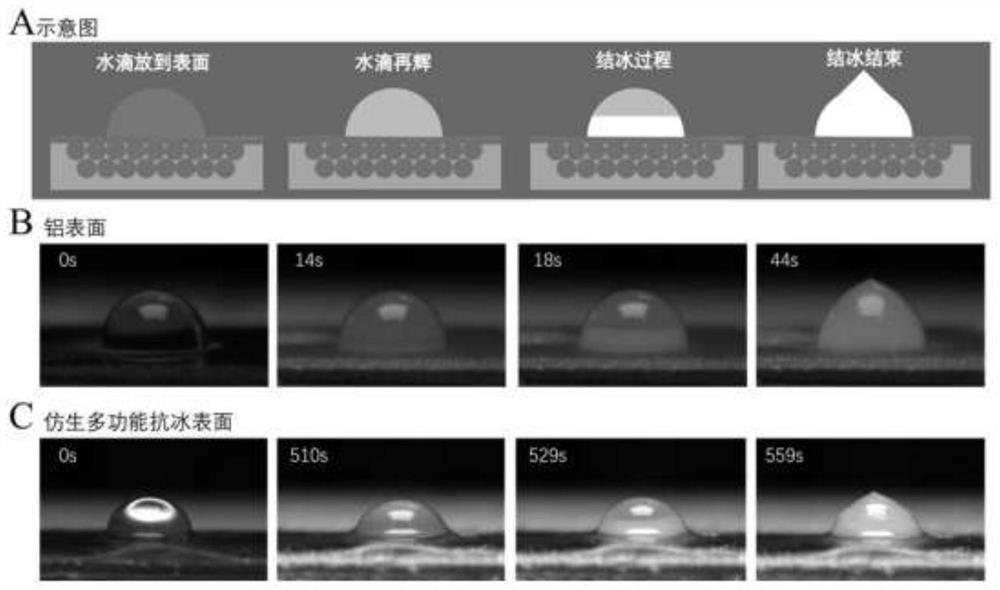

An ice surface, multi-functional technology, applied in the field of bionic multi-functional anti-icing surface, can solve the problem of not having the synergistic function of inhibiting icing, and achieve the effects of reducing ice adhesion, inhibiting ice nucleation, and delaying ice nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

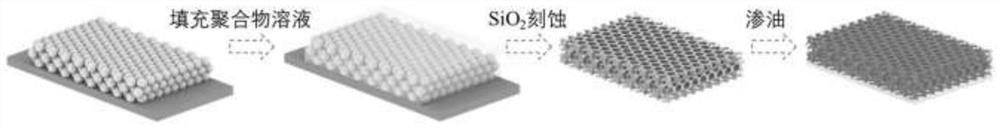

[0034] A biomimetic multifunctional anti-ice surface and a preparation method thereof, wherein the biomimetic multifunctional surface includes elastic polyurethane anti-opal film and perfluorinated oil. Such as figure 1 Shown, its preparation method is as follows:

[0035] By using a vertical deposition method, SiO with a size of 200 nm 2 Nanoparticles self-assemble on a glass slide to obtain a colloidal crystal template with an ordered array structure. In order to enhance SiO 2 The close-packed structure of nanoparticles, the glass slide and the fabricated colloidal crystal array were sintered at 400°C in a muffle furnace. Then, carbon black with a characteristic size of 300 nm and a polymer were mixed according to a mass ratio of 5:100 to prepare a polymer solution. Next, the inverse opal structure is formed by filling the polymer solution into the colloidal crystal template and evaporating the solvent to solidify the polymer. After the solvent evaporated completely, hy...

Embodiment 2

[0040] A biomimetic multifunctional anti-ice surface and a preparation method thereof, wherein the biomimetic multifunctional surface includes elastic polyurethane anti-opal film and liquid paraffin. Such as figure 1Shown, its preparation method is as follows:

[0041] By using a vertical deposition method, SiO with a size of 200 nm 2 Nanoparticles self-assemble on a glass slide to obtain a colloidal crystal template with an ordered array structure. In order to enhance SiO 2 The close-packed structure of nanoparticles, the glass slide and the fabricated colloidal crystal array were sintered at 400°C in a muffle furnace. Then, carbon nanotubes with a characteristic size of 300 nm and a polymer were mixed according to a mass ratio of 5:100 to prepare a polymer solution. Next, the inverse opal structure is formed by filling the polymer solution into the colloidal crystal template and evaporating the solvent to solidify the polymer. After the solvent evaporated completely, hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com