Pentazole lead composite salt and preparation method thereof

A technology of lead pentazole and compound salt, which is applied in the field of solid propellant combustion catalysis, can solve the problems that the catalyst does not contain energy and the propellant combustion performance is greatly affected, and achieves the effect of excellent detonation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

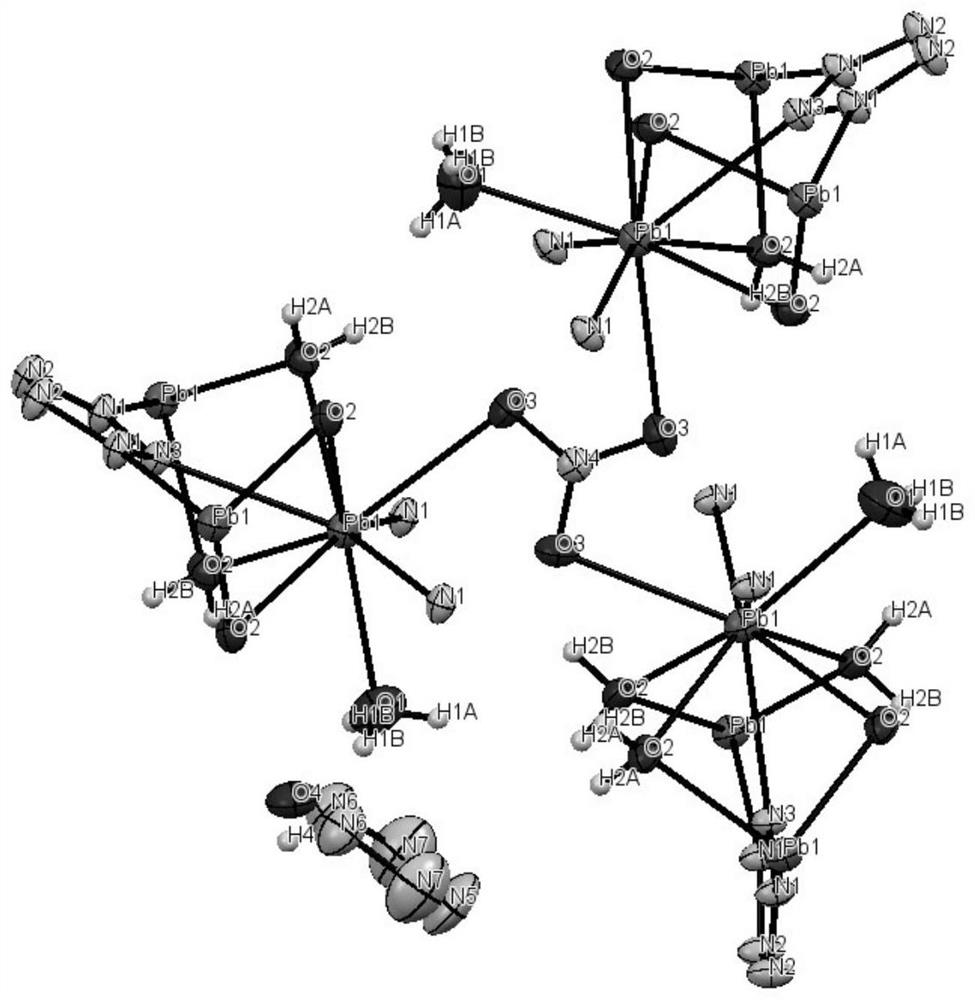

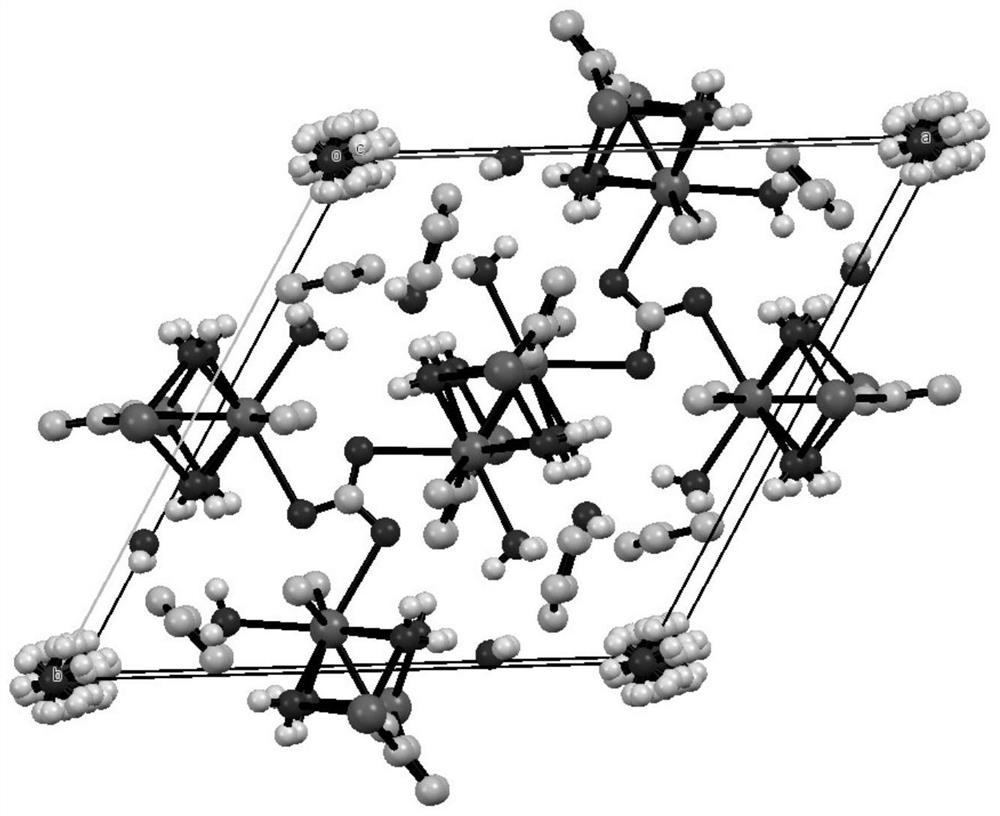

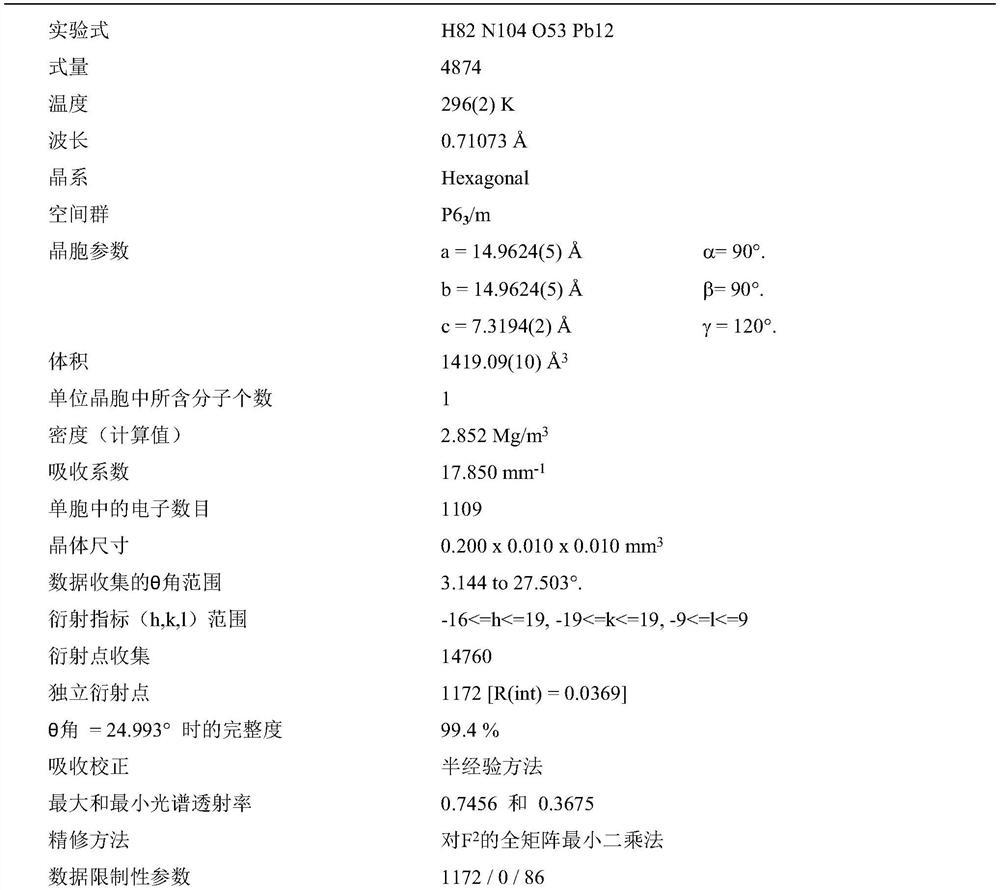

[0031] Example 1: Disperse 0.5 mmol of silver pentazole as a solid in 5 mL of deionized water at 5°C, add 0.5 mmol of lead chloride aqueous solution thereto, stir ultrasonically at 10°C for 1 hour, and then filter to obtain an aqueous solution of lead pentazole; Add 0.1 mmol of lead nitrate solid to the aqueous solution of lead pentazole, stir at room temperature for 0.5 h, take the clear liquid after filter membrane filtration and place it in a constant temperature and humidity box, set the temperature at 40°C, and set the humidity at 15%, so that the solvent evaporates quickly until The solvent is evaporated to 1 / 2, and then the temperature is set to 15°C, the humidity is 60%, and the solvent is slowly evaporated to obtain Pb 12 (N 5 ) 20 (NO 3 ) 4 (H 2 O) 41 Crystal 120mg.

Embodiment 2

[0032]Example 2: Disperse 0.5 mmol of silver pentazole as a solid in 5 mL of deionized water at 30° C., add 0.5 mmol of lead sulfate in water, stir ultrasonically at 30° C. for 1 hour, and then filter to obtain an aqueous solution of lead pentazole; Add 0.1 mmol lead nitrate solid to the pentazole lead aqueous solution, stir at room temperature for 0.5 h, take the clear liquid after filter membrane filtration and place it in a constant temperature and humidity box, set the temperature at 60°C, and set the humidity at 15%, so that the solvent evaporates quickly until the solvent Volatilize to 1 / 2, then set the temperature to 15°C and humidity to 60% to slowly evaporate the solvent to obtain Pb 12 (N 5 ) 20 (NO 3 ) 4 (H 2 O) 41 Crystal 100mg.

Embodiment 3

[0033] Example 3: Disperse 0.5 mmol of silver pentazole as a solid in 5 mL of deionized water at 25° C., add 0.42 mmol of lead chloride aqueous solution thereto, stir ultrasonically at 25° C. for 10 h, and then filter to obtain an aqueous solution of lead pentazole; Add 0.15 mmol of lead nitrate solid to the aqueous solution of lead pentazole, stir at room temperature for 3 hours, take the clear liquid after filtration through a filter membrane and place it in a constant temperature and humidity chamber, set the temperature at 50°C, and set the humidity at 15%, so that the solvent evaporates quickly until the solvent Volatilize to 1 / 2, then set the temperature to 15°C and humidity to 60% to slowly evaporate the solvent to obtain Pb 12 (N 5 ) 20 (NO 3 ) 4 (H 2 O) 41 Crystal 135mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact sensitivity | aaaaa | aaaaa |

| Friction sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com