Carbonation-based lightweight co 2 Foam cement-based material and its optimized preparation method and application

A foamed cement, carbonization technology, applied in chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of high maintenance cost, difficult implementation, low strength, etc., and achieve easy control, obvious effect, and low consumables characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

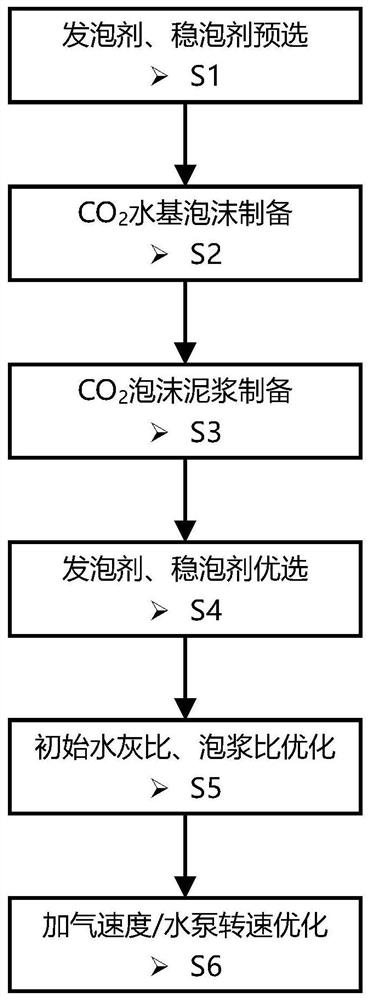

[0053] The present invention is based on carbonization of light CO 2 Optimal preparation method of foamed cement-based materials. The preparation method is as figure 1 shown, including the following steps:

[0054] Step S1: Investigate the types of foaming agents and foam stabilizers used in the existing lightweight mud, and select 6 types of foaming agents and foam stabilizers that are more commonly used.

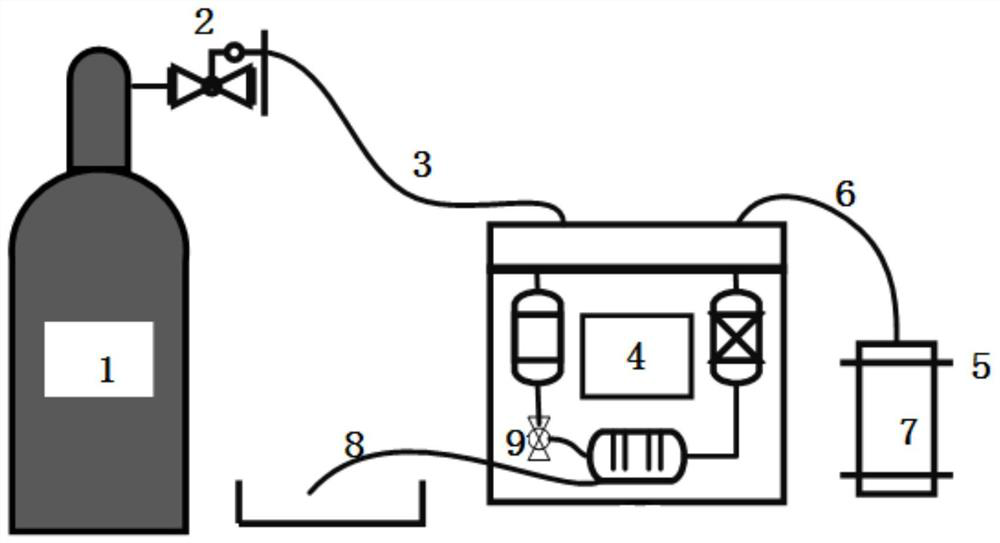

[0055] Step S2: Use figure 2 The carbon dioxide water-based foam foaming machine pre-tests the foaming agent and foam stabilizer in S1, and selects 3 kinds of foaming agents and 3 kinds of foam stabilizers according to the stability time and foaming height of the water-based foam to make carbon dioxide water-based Foam. like figure 2 As shown, the carbon dioxide water-based foam foaming machine includes a carbon dioxide gas cylinder 1, a primary pressure reducing valve 2, a secondary pressure reducing valve 9, an air storage tube 3, a liquid storage tube 5, a foamin...

Embodiment 2

[0077] The difference between this embodiment and embodiment 1 is only: the step S3 in embodiment 1: laboratory preparation grout is replaced by construction site preparation grout.

[0078] The steps for preparing grout at the construction site are as follows:

[0079] After the cement slurry is prepared, it is continuously stirred in the mixing tank. The foaming device absorbs the foaming liquid of appropriate concentration and fully foams it in the foaming tank. The mixing tank and the foaming tank are connected to the long conveying pipeline through a valve. Open the valve to mix the water-based foam and mud in the conveying pipeline, and pump delivered to the specified location.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com