Ultrathin high-strength alloy tungsten wire diamond fretsaw and preparation method thereof

A technology of diamond wire saw and diamond particles, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tool manufacturing, etc., can solve the problem that the surface cleanliness of tungsten wire cannot be guaranteed, cannot match the production speed of diamond wire, and the oxidation It is difficult to remove residues and other problems, and achieve the effect of high torsion value, low resistivity and enhanced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

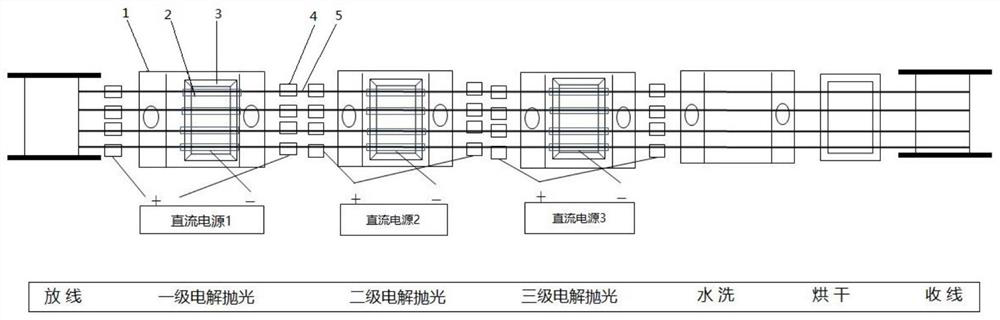

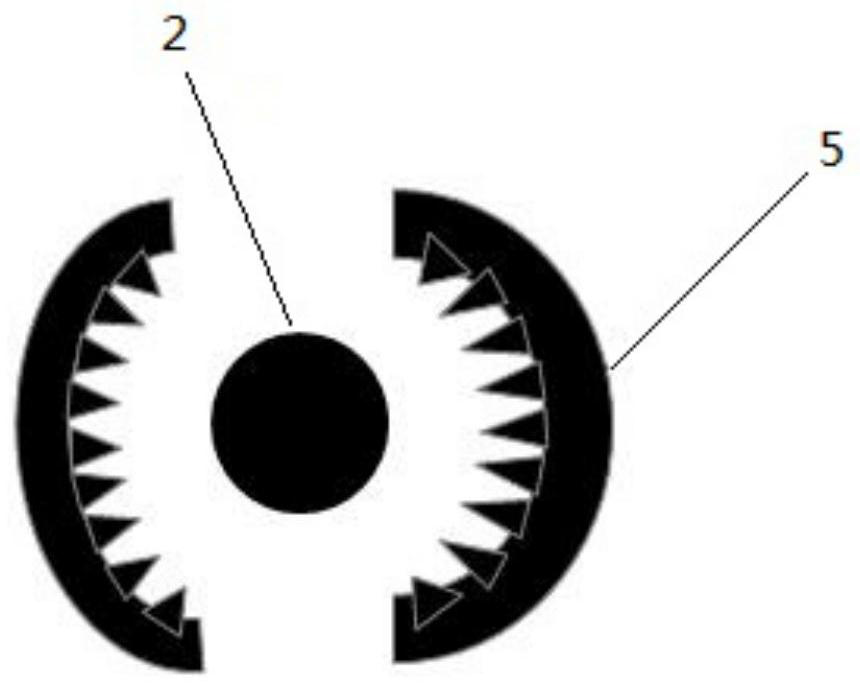

[0048] In this embodiment, use a black tungsten wire with a diameter of 45um as the busbar to prepare an ultra-fine high-strength alloy tungsten wire diamond wire saw with a specification of H-40, such as Figure 1-3 Shown, preparation process of the present invention comprises the following steps:

[0049] Step 1. The black tungsten wire goes through unwinding → three-stage electrolytic polishing → washing → drying → winding to prepare white tungsten wire;

[0050] Step 2. The scheelite wire obtained after the step 1 treatment is subjected to setting-off→secondary degreasing→water washing→pickling→water washing→impact nickel→sanding→sand fixing→water washing→heat treatment→winding to obtain target product.

[0051] The three-stage electrolytic polishing process in step one includes:

[0052] (1) The first-level electrolytic polishing process parameters include: 170g / L NaOH, 40g / L K 2 CO 3 , the electrolytic polishing temperature is 20°C, the flow rate of the polishing flu...

Embodiment 2

[0064] Use black tungsten wire with a diameter of 42um in this embodiment as the superfine high-strength alloy tungsten wire diamond wire saw of H-38 as the busbar preparation specification, such as Figure 1-3 Shown, preparation process of the present invention comprises the following steps:

[0065] Step 1. The black tungsten wire goes through unwinding → three-stage electrolytic polishing → washing → drying → winding to prepare white tungsten wire;

[0066] Step 2. The white tungsten wire treated in the step (1) is subjected to setting-off→secondary degreasing→water washing→pickling→water washing→impact nickel→sanding→sand fixing→water washing→heat treatment→winding to obtain target product.

[0067] The three-stage electrolytic polishing process in step one includes:

[0068] (1) The first-level electrolytic polishing process parameters include: 170g / L NaOH, 40g / L K 2 CO 3 , the electrolytic polishing temperature is 20°C, the flow rate of the polishing fluid is 200L / mi...

Embodiment 3

[0080] In this embodiment, an alloy tungsten wire with a diameter of 39um is used as a busbar to prepare an ultra-fine high-strength alloy tungsten wire diamond wire saw with a specification of H-35, such as Figure 1-3 Shown, preparation process of the present invention comprises the following steps:

[0081] Step 1. The black tungsten wire goes through unwinding → three-stage electrolytic polishing → washing → drying → winding to prepare white tungsten wire;

[0082] Step 2. The white tungsten wire treated in the step (1) is subjected to setting-off→secondary degreasing→water washing→pickling→water washing→impact nickel→sanding→sand fixing→water washing→heat treatment→winding to obtain target product.

[0083] The three-stage electrolytic polishing process in step 1 includes:

[0084] (1) The first-level electrolytic polishing process parameters include: 170g / L NaOH, 40g / L K 2 CO 3 , the electrolytic polishing temperature is 20°C, the flow rate of the polishing fluid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com