Laser sintering forming method

A laser sintering molding and laser technology, which is applied in laser welding equipment, manufacturing tools, and improving energy efficiency, can solve problems such as inability to guarantee connection reliability, and achieve the effects of improving connection reliability, enhancing bonding, and stabilizing the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

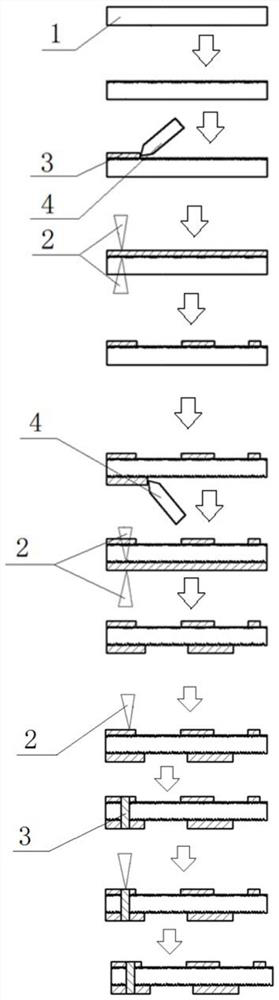

[0032] Such as figure 1 Shown is the first embodiment of a laser sintering molding method of the present invention, including the following steps:

[0033] First roughen the glass carrier 1, preferably, roughen the glass carrier 1 by physical engraving or chemical etching, so that the subsequent metal can be applied to the glass carrier 1 and increase the friction between the metal and the glass carrier 1 The force makes it easier for the metal to adhere to the glass carrier 1.

[0034] a. Smear the paste 3 containing nano-metal particles on the position to be sintered on the surface of one side of the glass carrier plate 1; when making the paste 3 containing nano-metal particles, the nano-metal particles need to be added to the organic alcohol reagent, Then add rosin and flux to form a paste 3 . When making the paste 3, the metal with the same particle size is used to make the paste 3, which can make the fusion of the metal and the glass carrier 1 more uniform, and keep the...

Embodiment 2

[0054] The following is the second embodiment of a laser sintering molding method of the present invention. This embodiment is similar to Embodiment 1, except that the particle size of the nano-metal particles used is 80nm, and the particle size is 80nm. The nano metal particles are added to the ethylene glycol solution to form a paste 3 with a solid content of 85%; the paste 3 is evenly spread on the roughened glass carrier 1 through the drip nozzle 4, and the thickness of the applied paste 3 is 4 μm. As in Example 1, laser irradiation was performed on both sides of the glass carrier 1 and the paste 3 respectively; and then cleaned with ethylene glycol solution to complete single-sided sintering of the surface of the glass carrier 1 . Repeat the above steps until the sintering of the surface on the other side of the glass carrier 1 is completed; after the paste 3 is sintered and cleaned, use a high-power laser to drill a circular hole with a diameter of 4 μm, add the above pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com