Tricholoma matsutake soy sauce and preparation process thereof

A preparation process, matsutake technology, applied in food science, food preservation, food ingredients as anti-microbial preservation, etc., can solve the problems of additive sensitivity and adverse health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

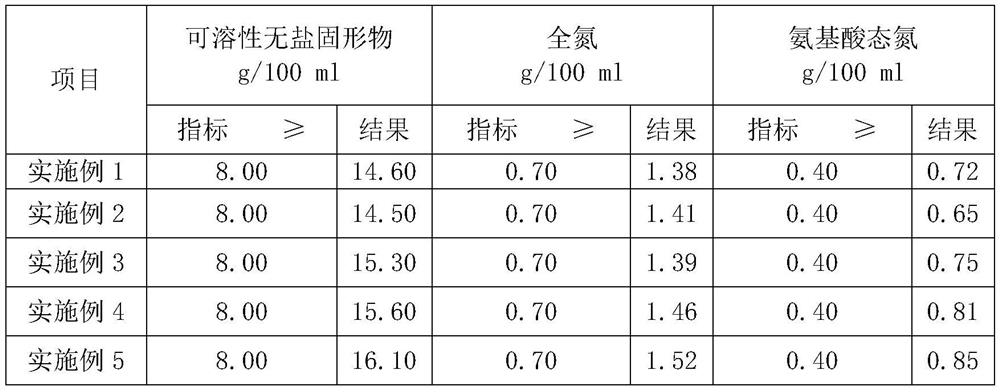

Embodiment 1

[0068] This embodiment provides a kind of matsutake soy sauce, which is prepared by the following process:

[0069] Raw material processing: Soak soybeans and wheat in water for 3 hours, then drain the water, add matsutake, and cook for 5 hours; crush the cooked raw materials into pieces with a diameter of 1mm, and set aside; the weight of matsutake, wheat and soybeans The ratio is 1:1:5;

[0070] Fermentation into the vat: After cooling the crushed raw materials, spread them on the bamboo fence, put them into the fermentation room, and ferment them at 37°C for 10 days, then put water, salt and fermented raw materials into one layer of raw materials, one layer of salt , the order of adding water once is added alternately, and finally the salt is on the top layer, and then the upper cover is sealed for 70 days; wherein the weight ratio of the above-mentioned fermentation raw materials to the above-mentioned water is 1:1, and the amount of the above-mentioned salt is 10% of the ...

Embodiment 2

[0074] This embodiment provides a kind of matsutake soy sauce, which is prepared by the following process:

[0075] Raw material processing: Soak soybeans and wheat in water for 6 hours, then drain the water, add matsutake, and cook for 8 hours; crush the cooked raw materials into pieces with a diameter of 5mm, and set aside; the weight of matsutake, wheat and soybeans The ratio is 1:3:9;

[0076] Fermentation into the vat: After cooling the crushed raw materials, spread them on the bamboo fence, put them into the fermentation room, and ferment them at 45°C for 20 days, then put water, salt and fermented raw materials into one layer of raw materials, one layer of salt , the order of adding water once is added alternately, and finally the salt is on the top layer, and then the upper cover is sealed for 80 days; wherein the weight ratio of the above-mentioned fermentation raw materials to the above-mentioned water is 1:3, and the consumption of the above-mentioned salt is 20% of...

Embodiment 3

[0080] This embodiment provides a kind of matsutake soy sauce, which is prepared by the following process:

[0081] Raw material processing: Soak soybeans and wheat in water for 5 hours, then drain the water, add matsutake, and steam for 7 hours; crush the cooked raw materials into pieces with a diameter of no more than 5mm, and set aside; among them, matsutake, wheat and soybean The weight ratio is 1:2:8;

[0082] Fermentation into the vat: After cooling the crushed raw materials, spread them on the bamboo fence, put them into the fermentation room, and ferment them at 40°C for 15 days, then put water, salt and fermented raw materials into one layer of raw materials, one layer of salt , the order of adding water once is added alternately, and finally the salt is in the uppermost layer, and then the upper cover is sealed for 75 days; wherein the weight ratio of the above-mentioned fermentation raw materials to the above-mentioned water is 1:2, and the amount of the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com