Process and plasma reactor for the production of synthesis gas

A plasma and reactor technology, applied in the gas-to-gas reaction, plasma, hydrogen/syngas production, etc. in the plasma state, can solve the problem of unanticipated reforming methods, etc., and achieve high added value and large industrial needs Effect

Active Publication Date: 2021-08-17

PETROLEO BRASILEIRO SA (PETROBRAS) +1

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0016] Therefore, there are no reports in the prior art of a reactor powered by carbon dioxide plasma and a reforming process using this reactor for the production of syngas and nanostructured carbon with high thermal power

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

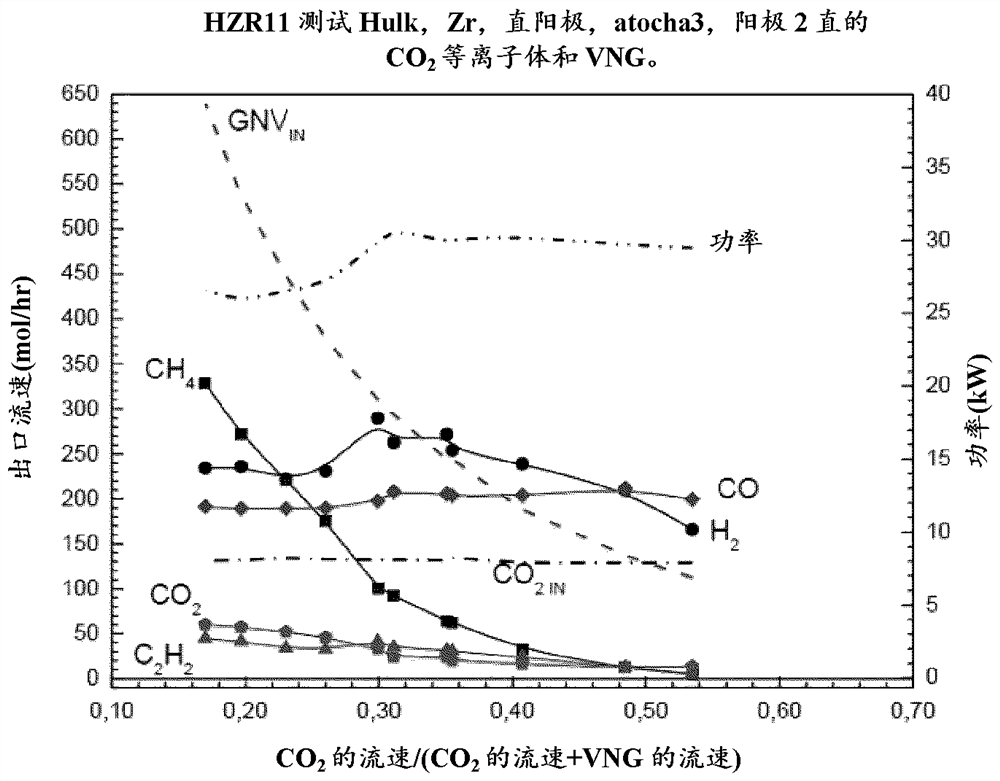

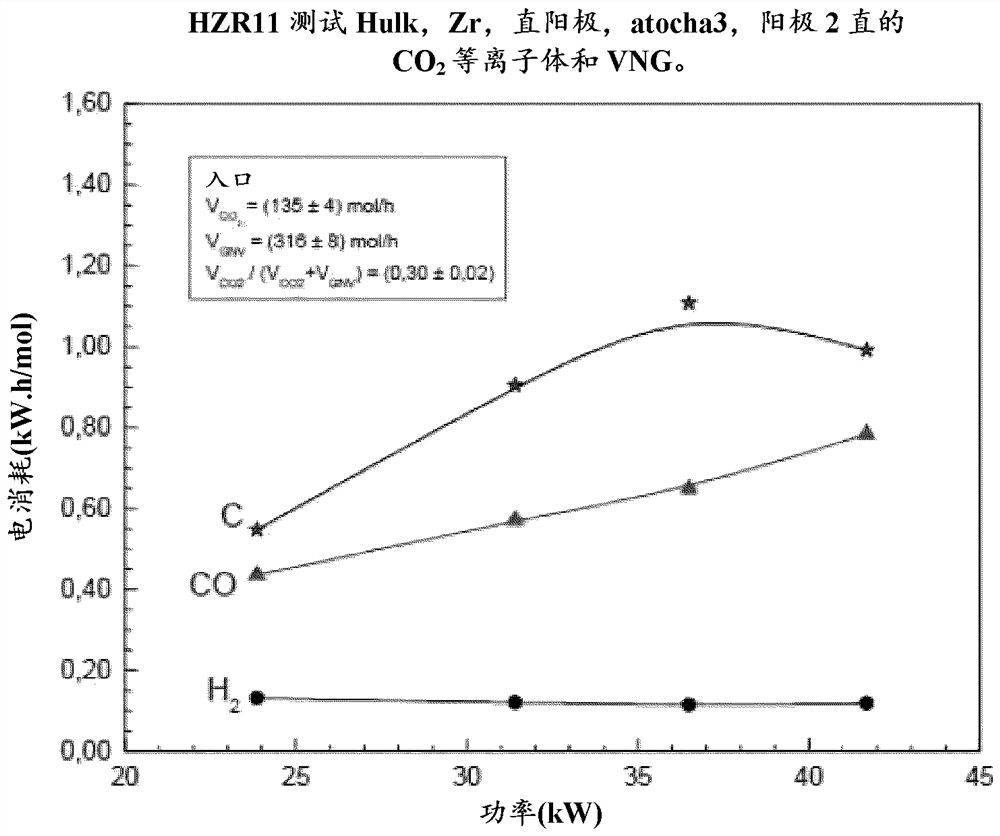

[0064] To better understand the processes taking place inside the plasma torch, Computational FluidDynamics (CFD - Computational Fluid Dynamics ) mock resource. The provided showed good energy efficiency in hydrogen production, however, the CO 2 conversion rate is low. In terms of efficiency and scale, the electric arc thermal plasma torch is in the conversion of natural gas to CO 2 Excellent results were achieved in plasma.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The present invention describes a plasma reactor for processing natural gas and / or light hydrocarbons, including biomethane and biogas, using a plasma torch that does not require the use of cathode-protection gas (shielding gas), and also a reforming process involving the use of a plasma reactor for the production of synthesis gas and carbonaceous materials from natural gas and / or light hydrocarbons.

Description

technical field [0001] The present invention relates to a method and a reactor for the production of synthesis gas. More specifically, the present invention proposes a reactor utilizing electric discharge and carbon dioxide, and a reforming process using this reactor for the production of synthesis gas with high thermal power and nanostructured carbon. Background technique [0002] Large-scale production of hydrogen and hydrogen-rich gases (called synthesis gas) for the refining industry, for the production of ammonia, methanol, liquid hydrocarbons from the "Fischer-Tropsch" process, for several A petrochemical method and a hydrogenation method. To obtain it, some hydrocarbon reforming (eg natural gas and / or other light hydrocarbons) processes may be used, such as steam reforming, partial oxidation, autothermal reforming or dry reforming. Currently, the steam reforming process of natural gas (methane and / or other light hydrocarbons) is the most common method for producing ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B3/34C09C1/48B01J19/08B01J12/00

CPCB01J19/088H05B7/18C01B3/34B01J2219/0809B01J2219/0841B01J2219/0875B01J2219/0898H05H1/00H05H1/48H05H2245/10C01B2203/0861C01B3/342C01B2203/0222B01J2219/0883B01J2219/0869B01J12/002C01B2203/1241H05H1/34

Inventor A·雷斯达科斯塔拉班卡A·贡萨尔维斯库尼亚

Owner PETROLEO BRASILEIRO SA (PETROBRAS)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com