A construction method for pipe jacking and cap excavation across the existing dense anchor cable area

A construction method and anchor cable technology, which are used in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as jamming cutter head, easy winding, damage, etc., and achieve road traffic restoration, soil filling and filling, and widespread promotion. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A construction method for pipe jacking and cap excavation across the existing dense anchor cable area, comprising the following steps:

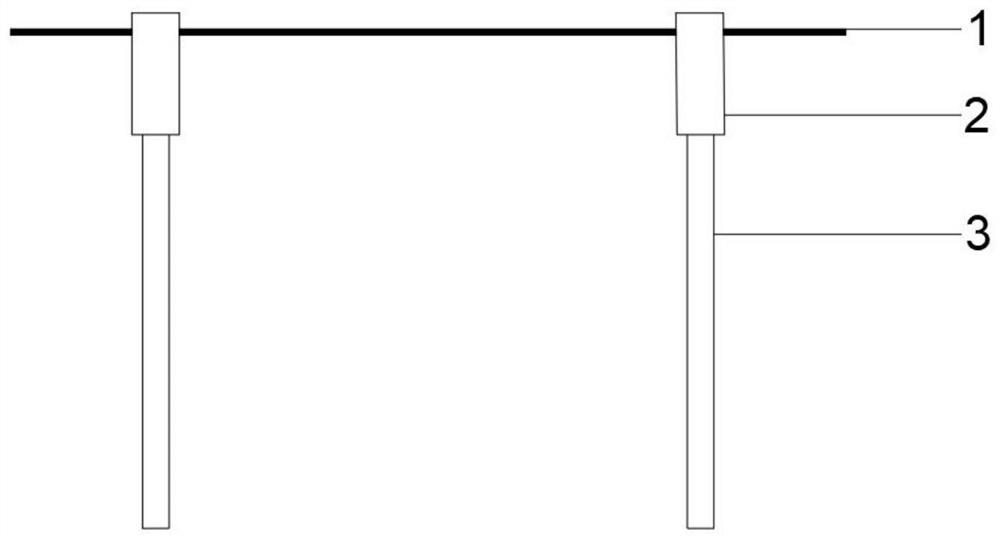

[0051] Such as figure 1 , the construction of the rotary excavation pile 3: arrange the rotary excavation pile 3 at the structural position of the existing anchor cable 5; bury the casing 2 after the mud is prepared, raise the top of the casing 2 above the ground by a preset distance, and set a overflow at the top Slurry port; then drill holes, when the drilled holes reach the preset depth, use the original slurry change slurry method to clear the holes; then lower the reinforcement cage, connect the reserved reinforcement bars of the reinforcement cage with the roof 11 reinforcement bars, and then pour concrete to the preset Set elevation;

[0052] Ground 1 unloading: unload the undisturbed soil within the scope of the roof 11 construction surface;

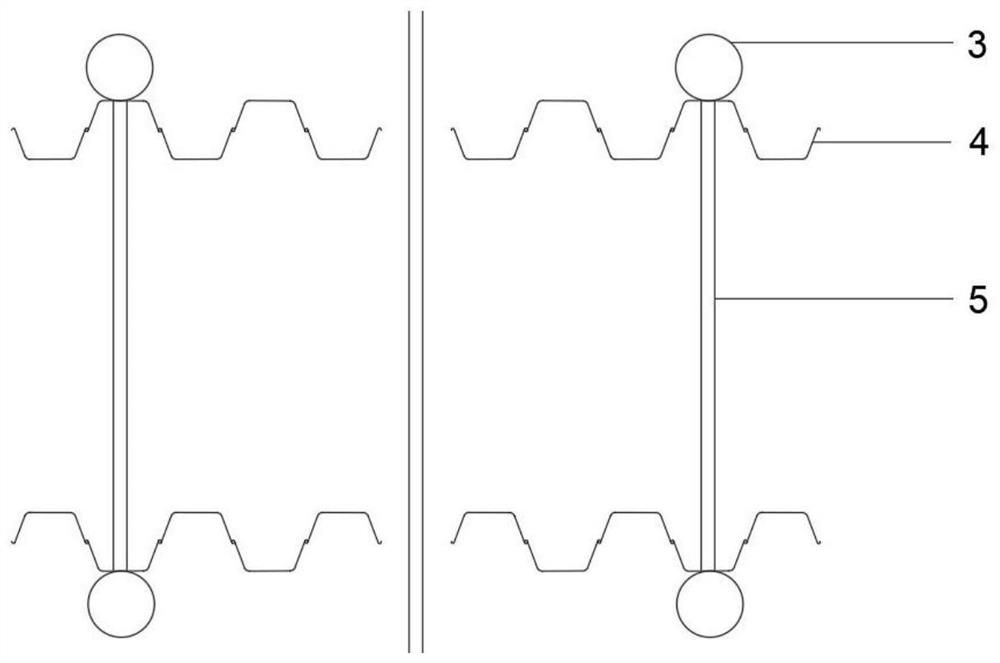

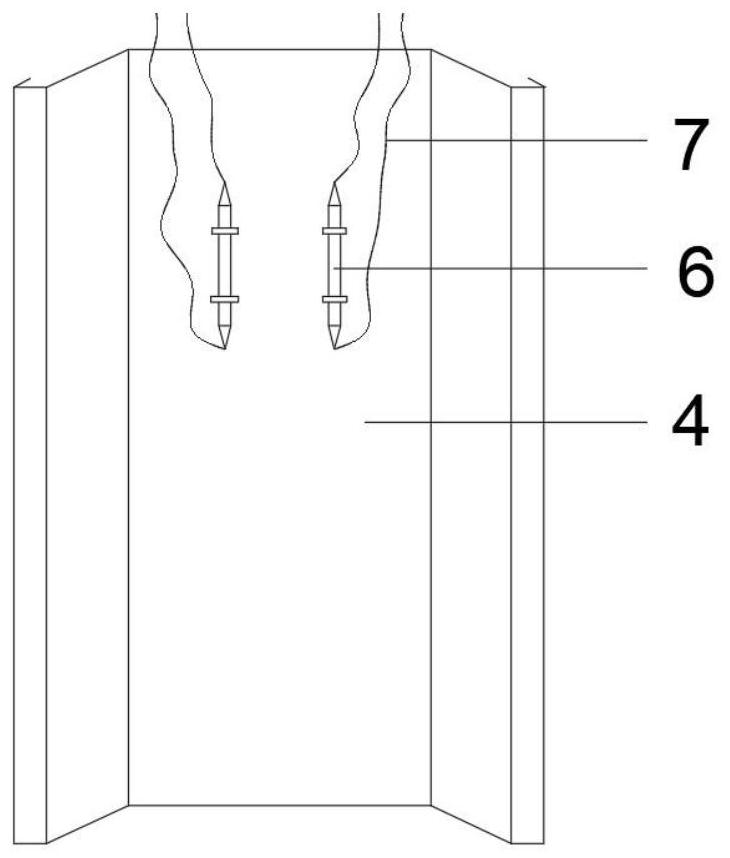

[0053] Such as figure 2 and image 3 , Larsen steel sheet pile construction: Larse...

Embodiment 2

[0061] A construction method for pipe jacking and cap excavation through the existing dense anchor cable area may further specifically include the following steps:

[0062] Pre-construction preparation: According to the construction drawings and site conditions, determine the relative position of the jacking route and the existing anchor cables 5, and determine the estimated range of the dense anchor cable groups that will affect the pipe jacking construction; The number of anchor cable 5 structures encountered during pipe crossing, the number of rotary excavation piles 3, steel sheet piles 4, and the construction quantity of rotary grouting piles 8 are judged in advance; Station positioning.

[0063] Construction of the rotary excavation pile 3: arrange the rotary excavation pile 3 at the structural position of the existing anchor cable 5, and make the interval between the piles of the rotary excavation pile 3 meet the load preset requirements; after preparing the mud, bury t...

Embodiment 3

[0075] A construction method for pipe jacking and cap excavation across the existing dense anchor cable area, in actual construction, may more specifically include the following steps:

[0076] Preparation before construction: Obtain the original support design drawings of adjacent foundation pits before construction, determine the jacking route and the relative position of the existing anchor cables 5 according to the construction drawings and site conditions, and determine the possible range of dense anchor cable groups that affect pipe jacking construction ; Based on this, determine the number of anchor cable 5 structures encountered when the pipe jacking passes through in the dense anchor cable group section, and judge the number of rotary excavation piles 3, steel sheet piles 4 and the construction quantity of rotary grouting piles 8 in advance, because rotary excavation When the pile 3 is drilled, the drill bit can cut the anchor cable 5, so the position of the rotary exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com