Grinding assembly of food waste disposer

A food waste treatment and assembly technology, which is applied to indoor sanitary piping devices, water supply devices, buildings, etc., can solve problems such as cutter head stuck, cutter head stuck, and reduced grinding performance of grinding components, so as to ensure the treatment effect, The effect of preventing jamming and preventing the cutter head from being jammed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

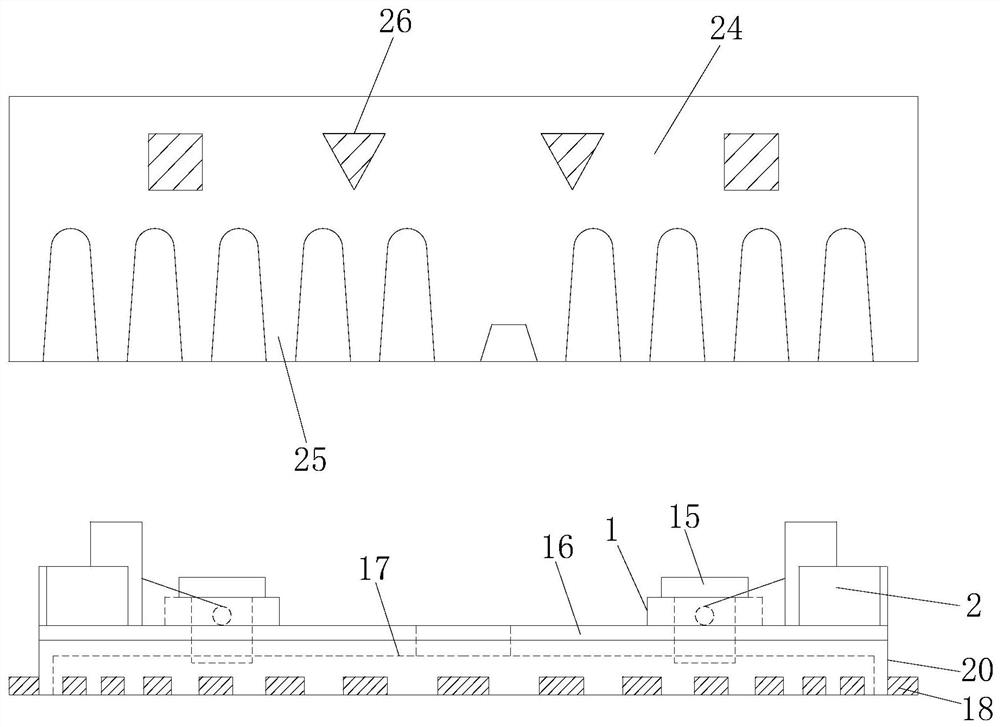

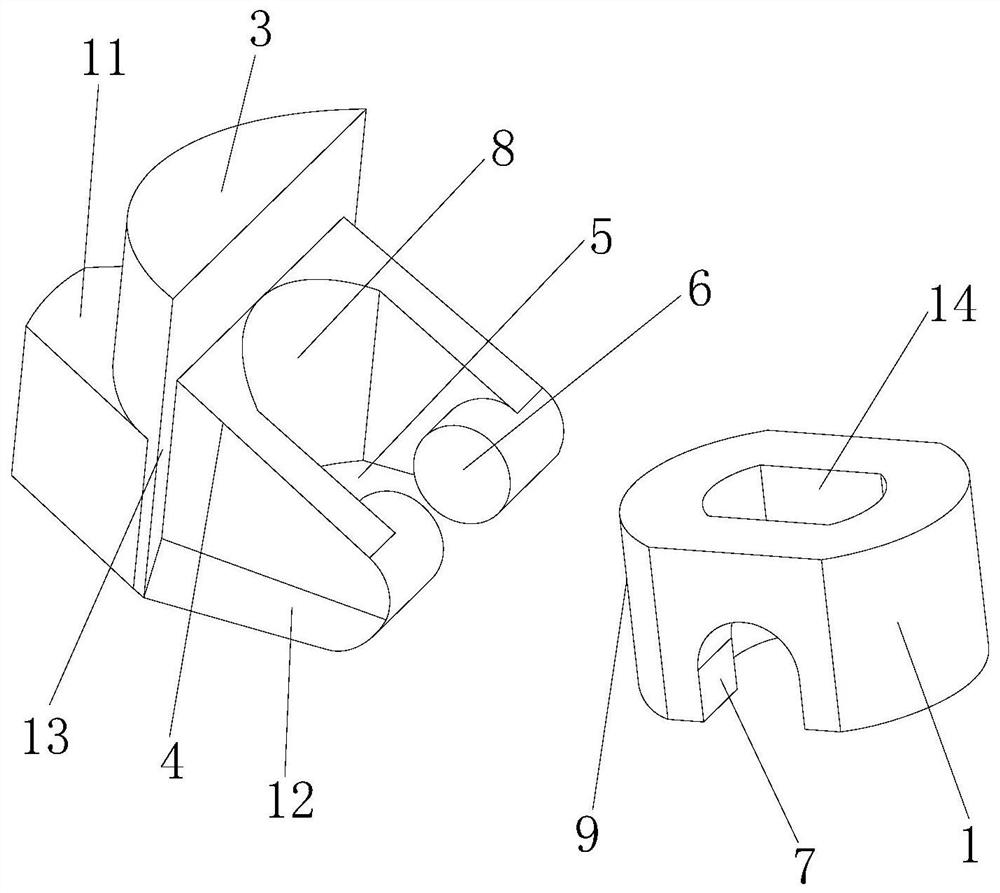

[0031] Such as Figure 1-Figure 6 As shown, this embodiment provides a grinding assembly for a food waste disposer, including a grinding ring 24 and a grinding disc 16 that cooperate with each other, and the grinding disc 16 is provided with a limitable and suspendable cutter head 2 . The grinding ring 24 is set on the outside of the grinding disc 16, and the cutter head 2 is located inside the grinding ring 24, and the cutter head 2 and the grinding ring 24 cooperate with each other to crush food waste. The limited suspended cutter head 2 can float within a certain range. When the food waste disposer disposes of garbage, since the cutter head 2 can be suspended, it can avoid jamming of the cutter head by cone-shaped (wedge-shaped) garbage, effectively preventing Blade 2 is stuck. The cutter head 2 of the present invention adopts a design structure that can be suspended, which can effectively prevent the cutter head 2 from being stuck and avoid the reduction of the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com