Manufacturing method of concrete spherical hinge with ultra-high performance

A concrete ball joint, ultra-high-performance technology, applied in construction, bridge construction, bridges, etc., can solve the problems of reduced reliability of ball joint rotation, great influence on the bearing capacity of ball joints, and difficulty in guaranteeing spherical surface processing accuracy, etc., to achieve improved Design pressure, save welding and inspection work, ensure the effect of stability and centering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

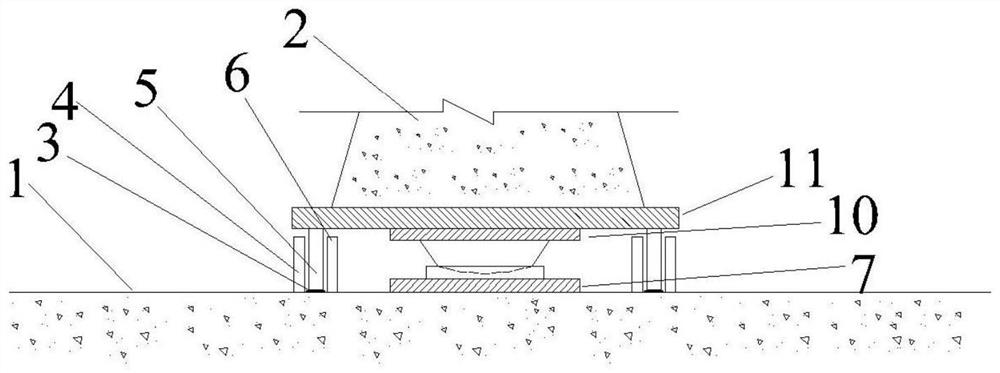

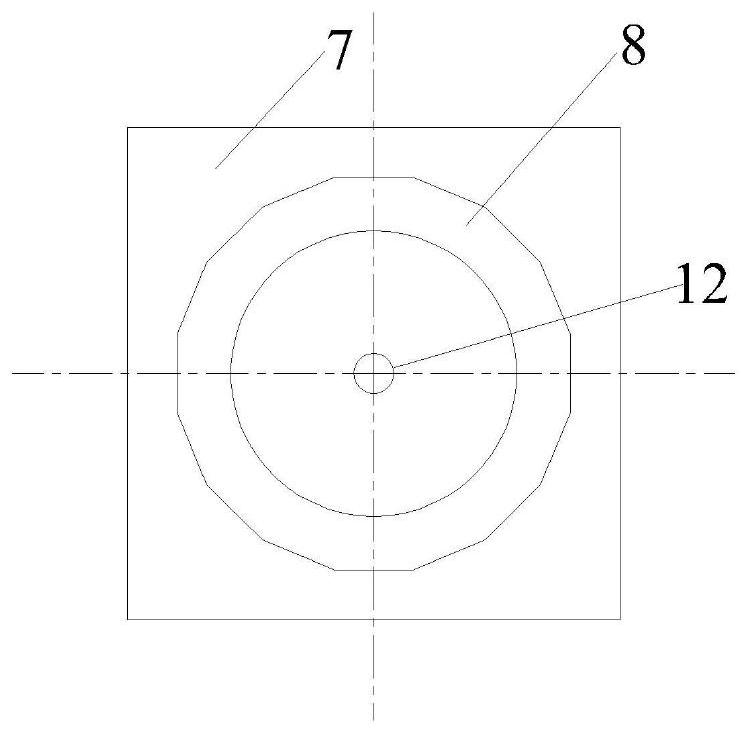

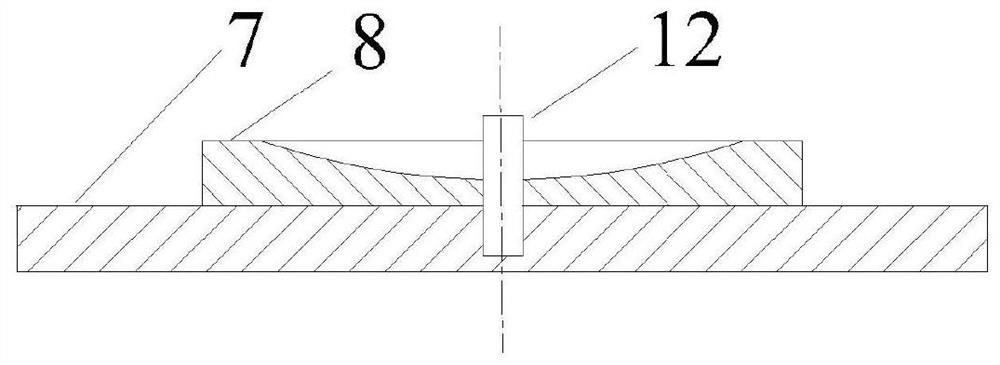

[0060] The schematic diagram of the position of the ball joint in the swivel device in this embodiment is shown in figure 1 , The surface layer of the lower ball joint is provided with 3 fiber orientation layers, the fibers in the middle layer are along the warp direction, and the fibers in the other two layers are along the weft direction (that is, the hoop direction). The spherical joint includes the upper spherical joint 9 and the lower spherical joint 8, both of which are made of steam-cured ultra-high performance concrete mixed with steel fibers. The 28-day compressive strength is greater than 150Mpa, the tensile strength is greater than 7.5Mpa, and the elastic modulus is greater than 40 GMPa. The diameter of the steel fiber is 0.2 mm and the length is 12 mm. Above the ball hinge is an inverted cone structure 13, an upper seat plate 10 is arranged between the inverted cone structure 13 and the turntable 11, and a lower seat plate 7 is arranged between the ball hinge and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com