Rotary fine-adjustment lifting appliance capable of arranging negative plate

A cathode plate and spreader technology, which is applied in the direction of load hanging components, hoisting equipment braking devices, cranes, etc., can solve the problems of corrosion of surrounding objects, increase the difficulty of lifting, and reduce the efficiency of lifting, so as to reduce labor costs, The effect of reducing the difficulty of lifting and improving the efficiency of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

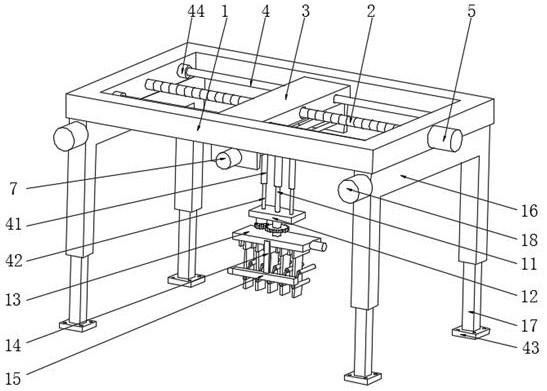

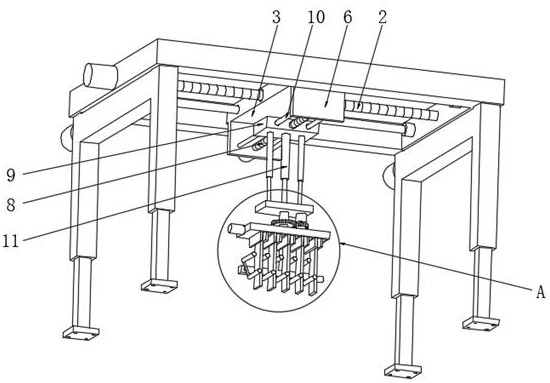

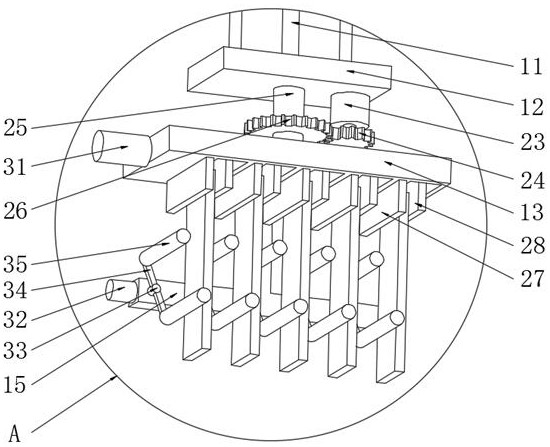

[0025] see Figure 1~6 , in an embodiment of the present invention, a rotating and fine-tuning cardable cathode plate hanger includes a main beam frame 1, the inner side of the main beam frame 1 is located at the middle position and is rotatably connected with a transverse screw rod 2, and the inner side of the main beam frame 1 is set There is a horizontal slide plate 3, and the horizontal screw rod 2 is connected with the internal rotation of the horizontal slide plate 3 through the thread. The inner side of the main beam frame 1 is fixed, and one end of the main beam frame 1 is installed at the position corresponding to the horizontal screw rod 2. The horizontal servo motor 5 is installed. Two end plates 6 are fixed at both ends of the side, between the two end plates 6 there is a longitudinal screw rod 8 which is rotated at the middle position, and the outer side of the longitudinal screw rod 8 is connected with a longitudinal slide plate 9 through the rotation of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com