Cleaning device for electromechanical overhaul

A cleaning device and electromechanical technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of irregular shape of the bottom of the engine, difficulty in cleaning the bottom of the engine, and increased difficulty of maintenance work, etc., to achieve Increase the convenience of observation, facilitate comprehensive and thorough cleaning, and increase the efficiency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

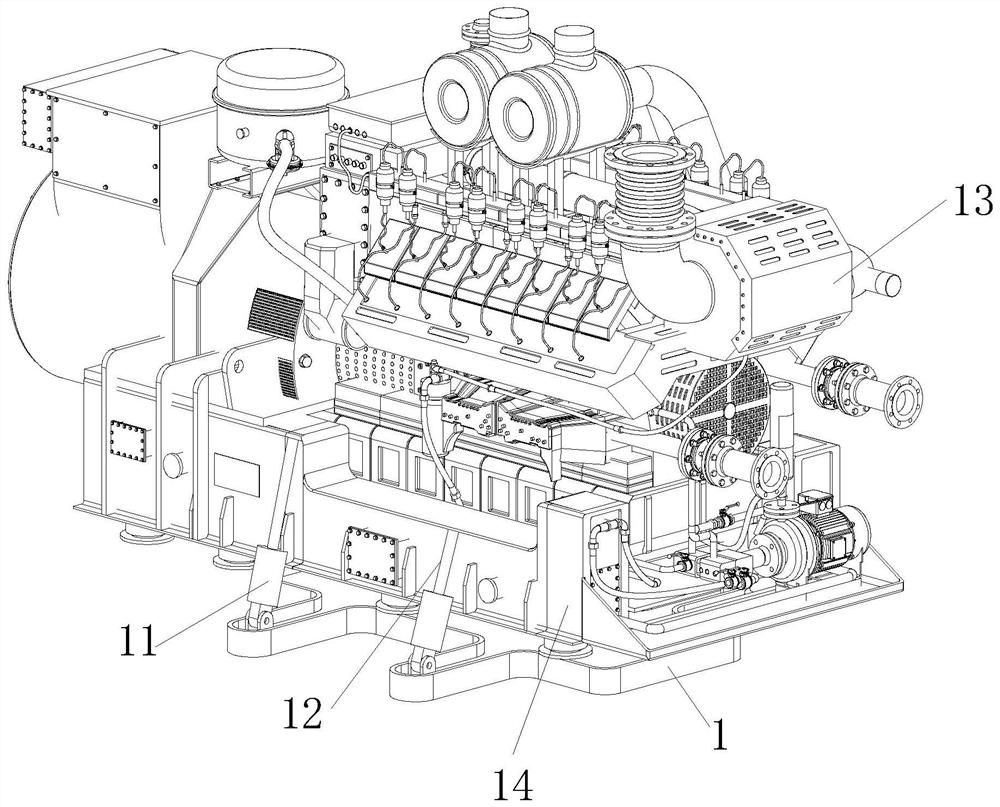

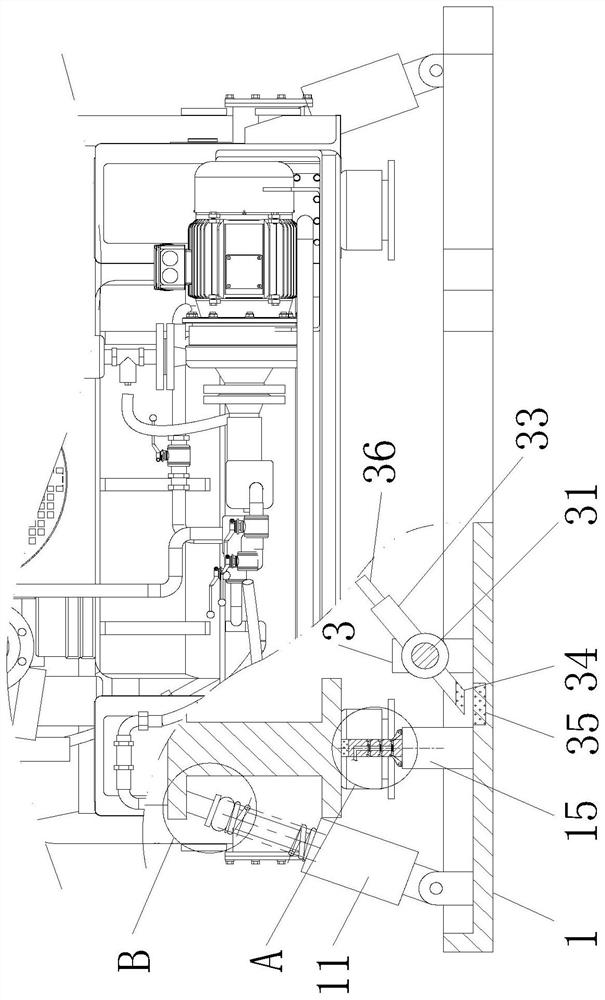

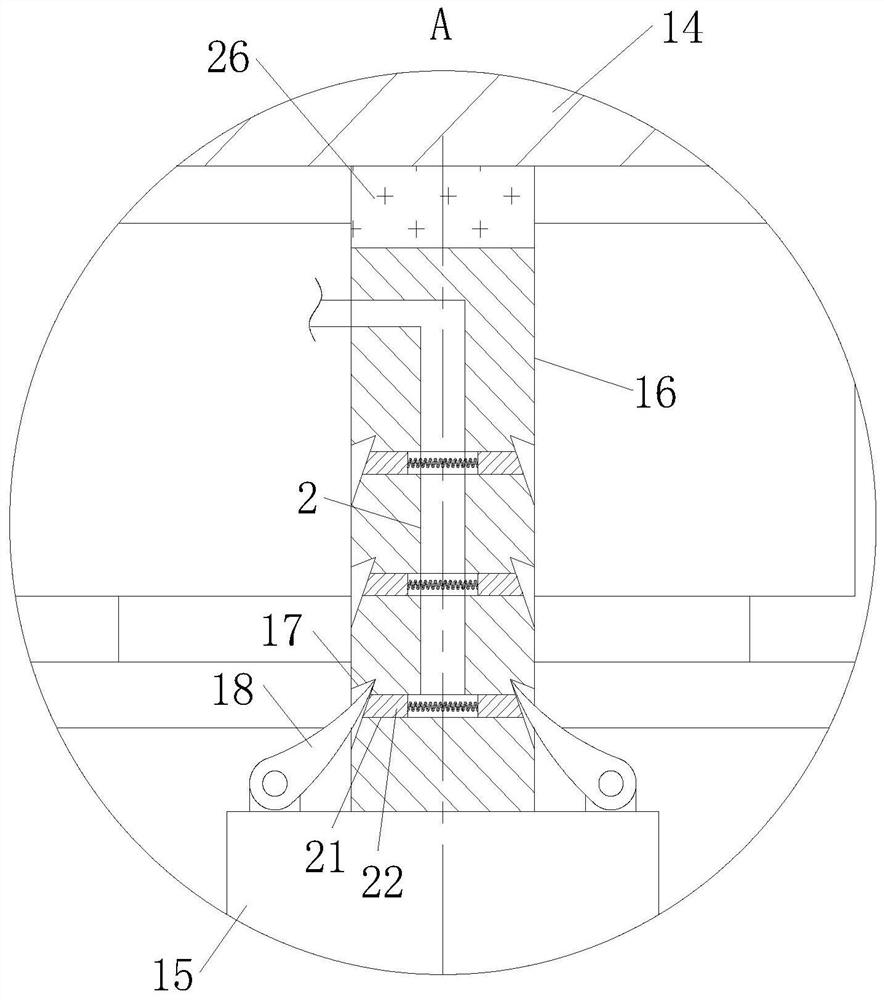

[0032] like Figure 1 to Figure 7As shown, a cleaning device for electromechanical maintenance according to the present invention includes a collection tray 1 and a hydraulic cylinder 11; a set of lugs are evenly distributed on both sides of the collection tray 1, and a set of lugs are hinged on the upper part of the lugs through a hinge support. Hydraulic cylinder 11, the free end of the piston rod 12 of the hydraulic cylinder 11 is against the side of the base 14 fixedly connected to the bottom of the engine 13; the middle part of the collection tray 1 is provided with a steam cleaning unit; the top of the collection tray 1 is adjacent to the base 14 A group of sliding cylinders 15 are fixedly connected at the corresponding positions between them. A push rod 16 is slidably connected to the sliding cylinder 15. A group of wedge-shaped grooves 17 are evenly distributed on the outer periphery of the push rod 16 in the vertical direction. The top of the sliding cylinder 15 and th...

Embodiment 2

[0042] like Figure 8 As shown, the top of the magnetic disc 26 is provided with a blind hole 27, and a set of chute 28 is evenly distributed on the periphery of the blind hole 27, and the chute 28 runs through the magnetic disc 26 and communicates with the bottom of the blind hole 27; 28, so that when the magnetic disk 26 is against the bottom of the base 14, the sludge between the magnetic column 35 and the base 14 is discharged through the blind hole 27 and the chute 28, reducing the slippage between the magnetic disk 26 and the base 14, and further increasing the push rod 16 Firm supports for the base 14.

[0043] When working, the present invention puts the collection tray 1 at the bottom of the base 14, aligns the piston rod 12 with the I-beam side wall outside the base 14, and then lifts the base 14 smoothly through the hydraulic cylinder 11, and cooperates with the push rod 16 to rise and reach Hold the bottom of the base 14, the ratchet 18 is inserted into the wedge-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com