Internal-climbing and jacking apparatus of tower crane, control method and tower crane

A technology of tower crane and jacking device, applied in cranes and other directions, can solve the problem of low working efficiency of inner climbing jacking device, and achieve the effect of reducing labor intensity and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

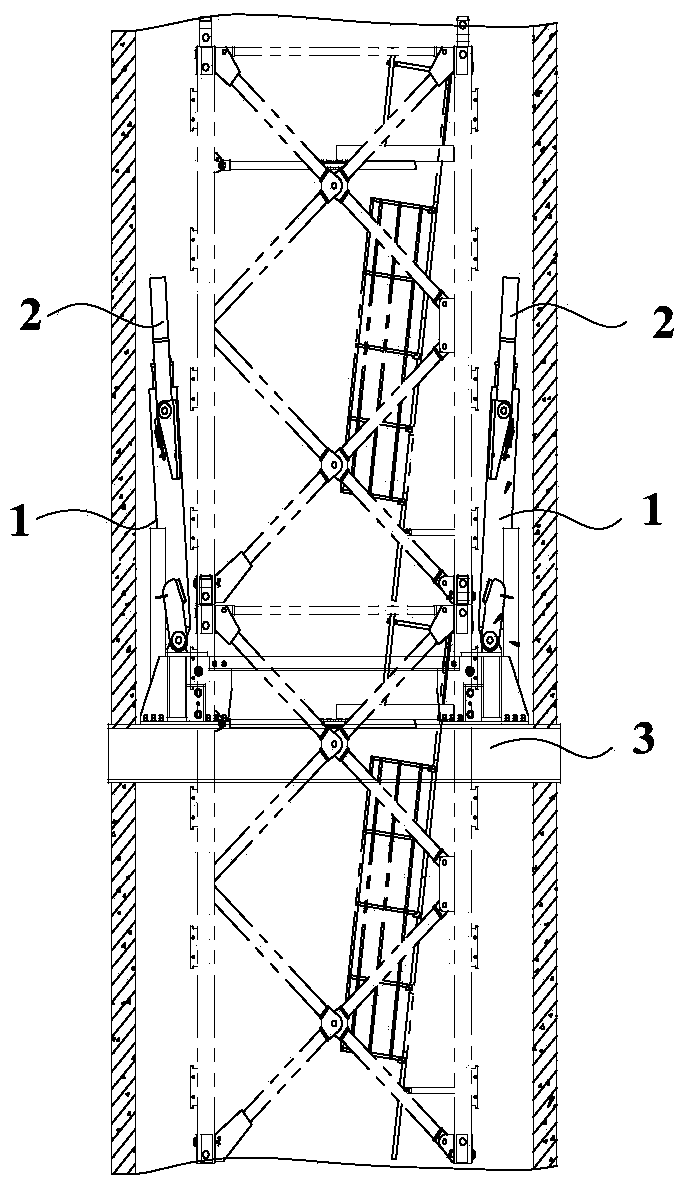

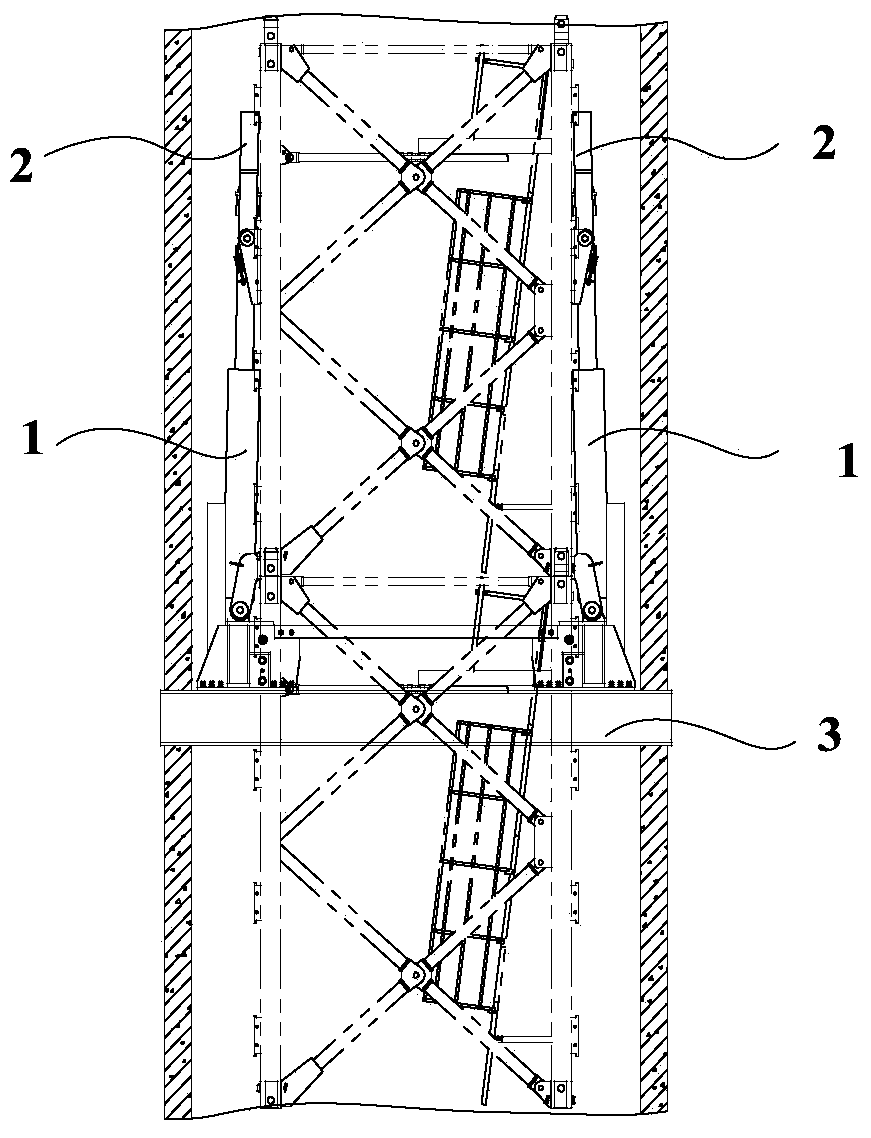

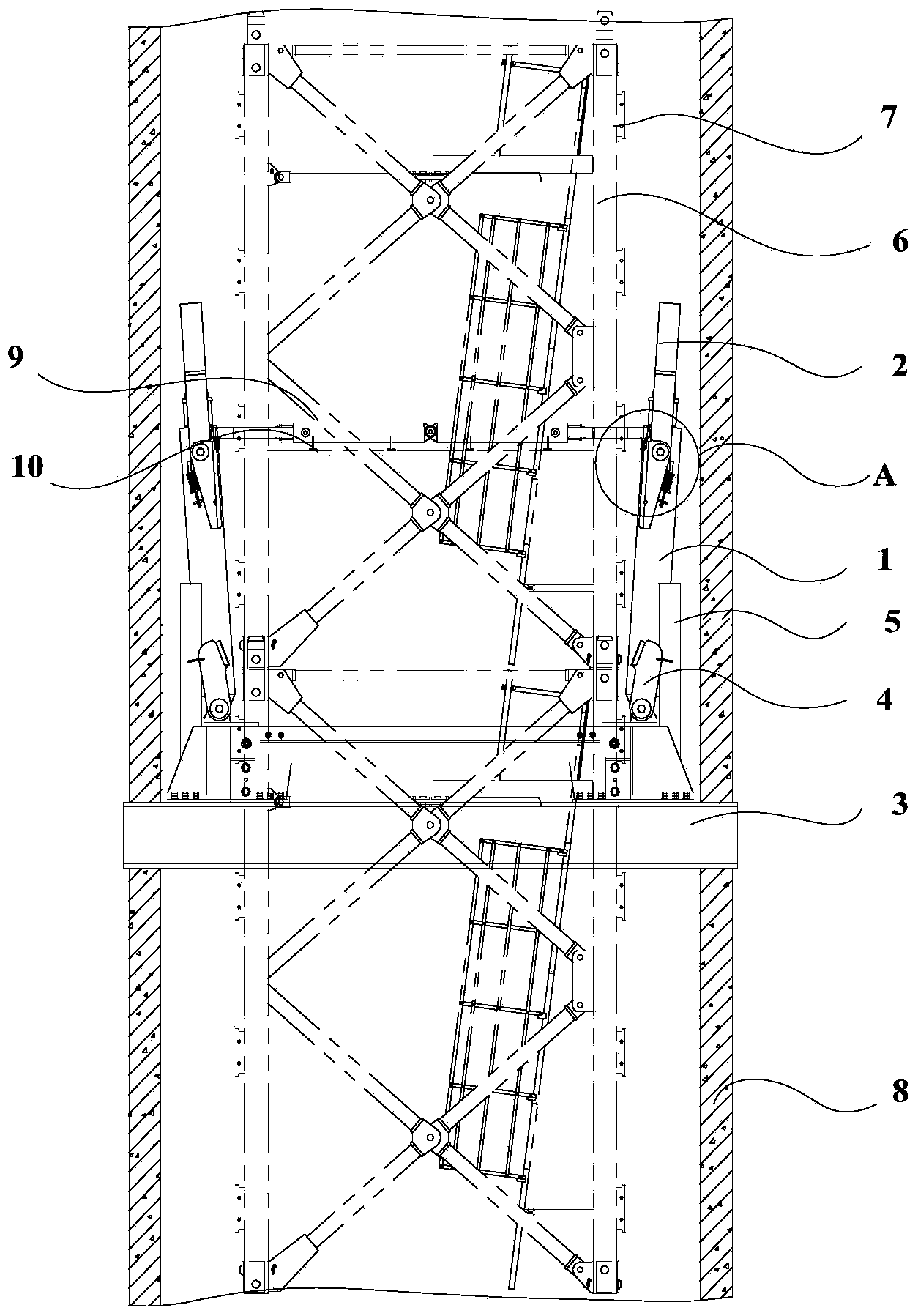

[0046] continue to refer image 3 , Figure 4 , Figure 5 , Image 6 as well as Figure 7 , the telescoping mechanism includes two small oil cylinders 9 connected by cylinders, and the piston rods 91 of the two small oil cylinders 9 are respectively connected with the cylinders of the corresponding jacking cylinders 1. Specifically, the cylinders of the two small oil cylinders 9 are respectively fixedly arranged On the small oil cylinder mount 10, two small oil cylinders 9 are fixedly connected together by the small oil cylinder mount 10, or one end of the two small oil cylinders 9 cylinder bodies is hinged away from its piston rod. Two piston rods 91 are connected with the cylinder body of corresponding jacking cylinder 1 through chain 12, meanwhile, the cylinder body of jacking cylinder 1 is provided with the concave seat 11 that cooperates with the piston rod 91 of small oil cylinder 9. When the piston rod 91 of the small oil cylinder 9 was stretched out, the top of the...

Embodiment 2

[0050] Such as Figure 8 as shown, Figure 8 Another structure of the telescopic mechanism is shown, and the telescopic mechanism includes connecting rods 15 respectively hinged to the cylinder body of each jacking cylinder 1, and the two connecting rods 15 are hingedly connected, and are arranged on the tower body standard The drive cylinder 16 on the platform in the section, and the top end of the piston rod of the drive cylinder 16 is hinged at the hinge between the two connecting rods 15. When the piston rod of the drive cylinder 16 shrinks, the jacking cylinder 1 is pulled close to the The direction of the tower body is rotated to the jacking position and locked, and when the piston rod of the drive cylinder 16 stretches out, the jacking cylinder 1 is pushed to rotate away from the tower body.

[0051] Specifically, the driving cylinder 16 is connected to the pumping station 14 that drives the jacking cylinder 1, and the driving cylinder 16 is driven by the pumping stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com