Tissue factor-loaded calcium carbonate particle self-propelled hemostatic dressing

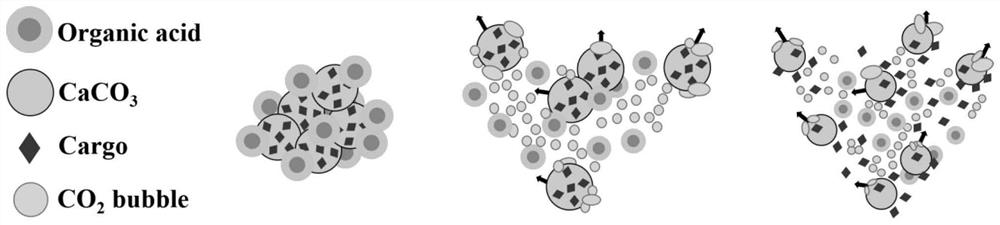

A tissue factor and hemostatic dressing technology, applied in the fields of application, medical science, pharmaceutical formulation, etc., can solve the problem of insufficiency of wounds, and achieve the effects of easy removal, avoidance of secondary damage, and high coagulation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

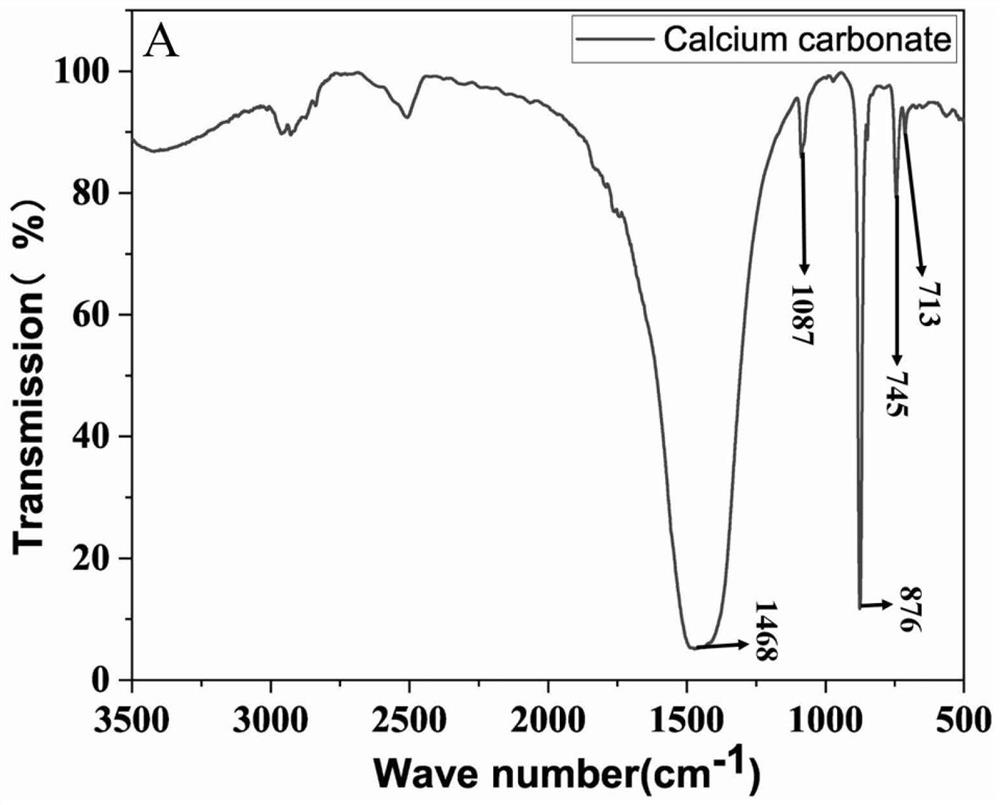

Method used

Image

Examples

Embodiment 1

[0026] (1) Expression and purification of tissue factor

[0027] A plasmid (pET-22b) carrying the tissue factor gene was transformed into bacterial cells. Place the cells in medium containing ampicillin and grow at 37 °C until A 600 Reach 0.6-0.8. The culture was then moved to 25°C and induced overnight with isopropyl-β-D-1-thiogalactopyranoside. The culture was centrifuged to obtain a pellet and suspended with Triton X-100 reagent. After lysing with a French press and centrifugation, the supernatant was collected into a new tube. Next, expressed tissue factor was purified from the supernatant by Ni-affinity chromatography in the presence of Tween 80.

[0028] (2) Preparation of tissue factor-integrated liposomes

[0029] The mixture of DOPC and DOPS was dried in a glass bottle and dissolved in Tris-HCl containing deoxycholate and tissue factor. The samples were stirred with the biobeads for 90 min at room temperature before adding part of the biobeads removal detergent ...

Embodiment 2

[0041] This example is the same as Example 1 except that the final concentration of tissue factor in step (3) is 3 nM, and other steps are the same.

Embodiment 3

[0043] This example is the same as Example 1 except that the final concentration of tissue factor in step (3) is 9 nM, and other steps are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com