A submarine cable bending protection system

A protection system and bending technology, applied in the installation of cables, the arrangement of cables between relatively moving parts, electrical components, etc., can solve the problems of easy corrosion, overbending of suspended sections, excessive bending of submarine cables, etc., and achieve impact resistance Strong, small swing, anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

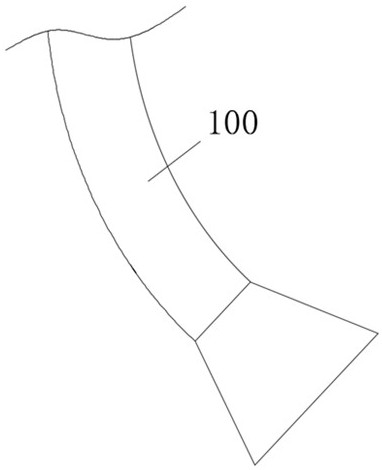

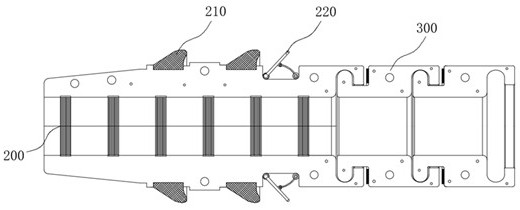

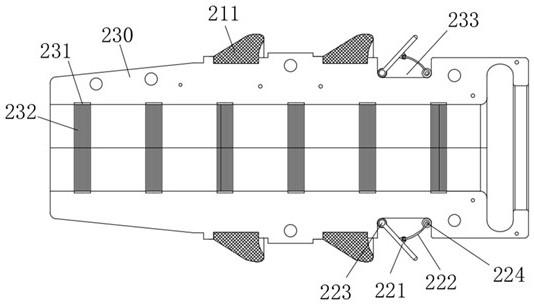

[0033] refer to Figure 1 ~ Figure 3 , in this embodiment, a submarine cable bending protection system is proposed, including a central positioning protection device and a bending protection device arranged in sequence. The central positioning protection device includes a protection body 200. The front end of the protection body 200 is tapered, and the protection body 200 is assembled On the submarine cable, the protective body 200 is used to assemble the submarine cable in the tail section of the curved pipe 100. The outer wall of the protective body 200 is sequentially equipped with an A positioning protection component 210 and a B positioning protection component 220, and the A positioning protection component 210 and the B positioning protection component The protection components 220 form an abutting fit with the inner wall of the curved pipe 100 to maintain the submarine cable at the center of the tail section of the curved pipe 100 .

[0034]The protective body 200 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com