Submarine cable bending protection system and device

A protection system and protection device technology, applied in the installation of cables, the arrangement of cables between relatively moving parts, electrical components, etc., can solve the problems of easy corrosion, performance impact, overbending of suspended sections, etc., and achieve impact resistance Strong, meet the requirements of use, the effect of small swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

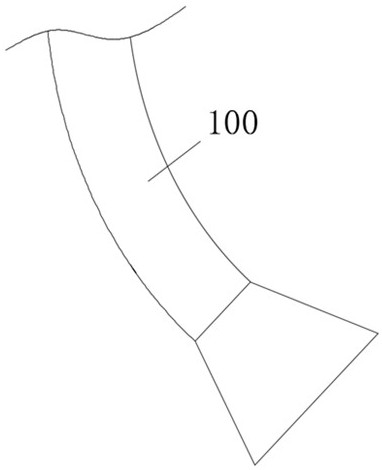

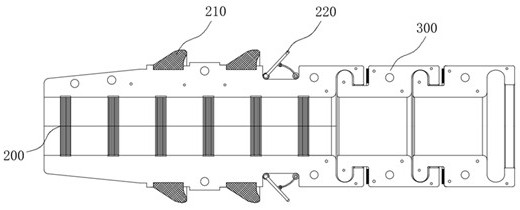

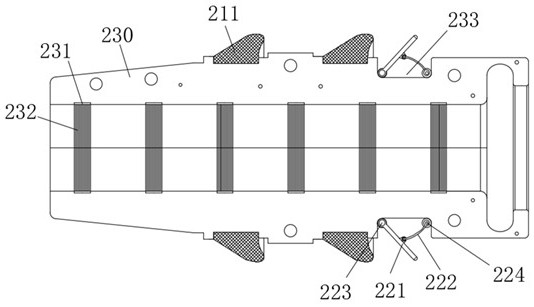

[0033] refer to Figure 1-3 , in this embodiment, a submarine cable bending protection system is proposed, including a central positioning protection device and a bending protection device arranged in sequence. The central positioning protection device includes a protection body 200. The front end of the protection body 200 is tapered, and the protection body 200 is assembled On the submarine cable, the protective body 200 is used to assemble the submarine cable in the tail section of the curved pipe 100. The outer wall of the protective body 200 is sequentially equipped with an A positioning protection component 210 and a B positioning protection component 220, and the A positioning protection component 210 and the B positioning protection component The protection components 220 form an abutting fit with the inner wall of the curved pipe 100 to maintain the submarine cable at the center of the tail section of the curved pipe 100 .

[0034]The protective body 200 is composed o...

Embodiment 2

[0044] refer to Figure 4-7 In this embodiment, a submarine cable bending protection device is proposed, which includes a bending limiter 300 and a limiting cable 400 connected end to end in sequence. The bending limiter 300 is composed of two bending limiting blocks 310, and the bending limiter 300 is installed on the outside There is a fixing component 320, and the limiting cable 400 is fixedly connected to the fixing component 320 on the outside of each bending limiter 300, and the limiting cable 400 is used to limit the bending range of the submarine cable.

[0045] The fixing components 320 are distributed in a circular array around the central axis of the bending limiter 300 , and the limiting cables 400 and the fixing components 320 on the bending limiter 300 are provided in one-to-one correspondence.

[0046] The fixing assembly 320 includes a cylindrical protrusion 321 . The protrusion 321 is provided with a threaded hole 323 . The hole of the threaded hole 323 is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com