Generator bar vibration optimization method based on modified long-short term memory neural network

A long-short-term memory, neural network technology, applied in the field of generator bar vibration optimization based on modified long-short-term memory neural network, can solve the problem of high cost, lack of historical data level mathematical support, unable to clearly give temperature adjustment direction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

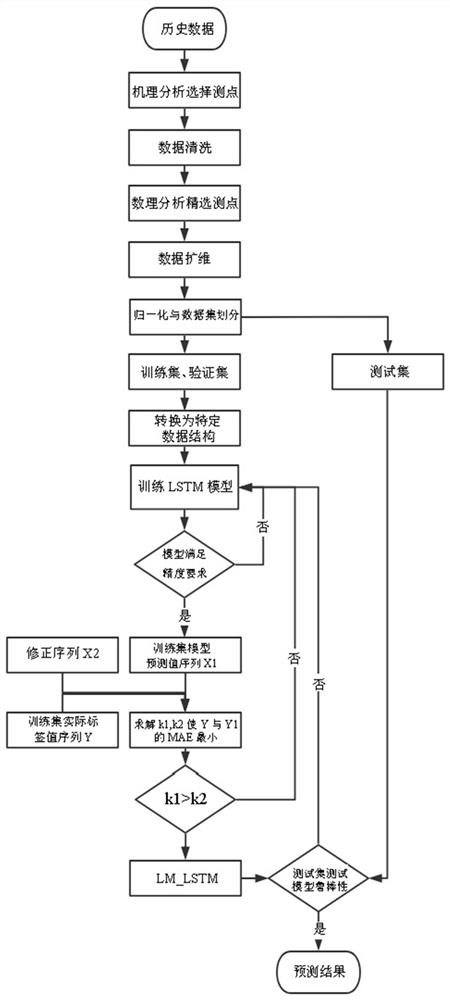

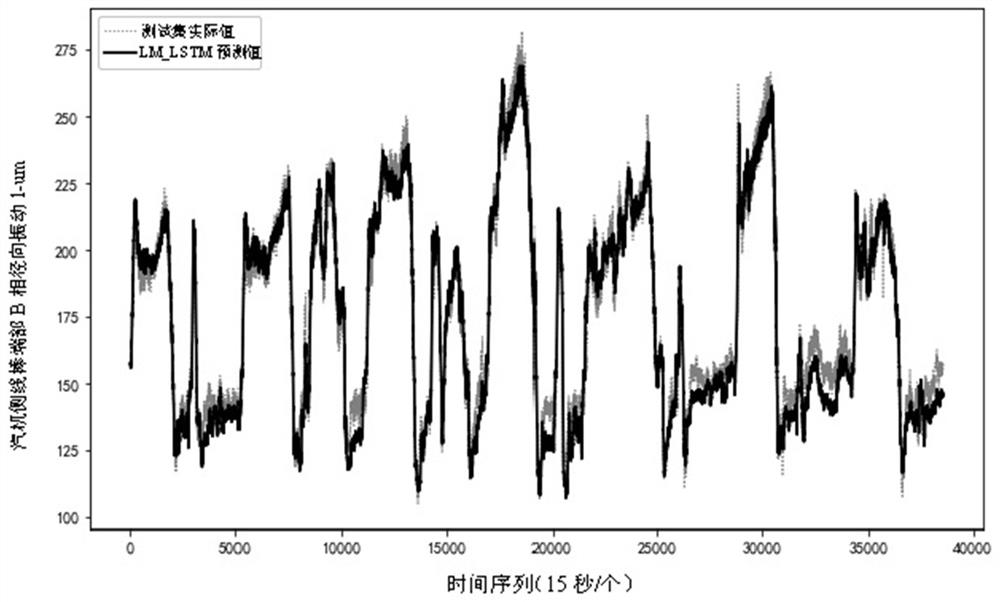

[0053] Using data from a 1050MW generator in a power plant, the radial vibration of the B-phase wire rod of the generator often exceeds the standard, and the highest value has reached 383um, which is much higher than the alarm value of 250um. Taking the vibration at the end of the B-phase wire rod of the generator as the research and verification object, a method for optimizing the vibration of the generator wire rod based on the modified long-short-term memory neural network, such as figure 1 shown, including steps:

[0054] Step 1. Train the generator bar vibration LM_LSTM (long short-term memory neural network) model;

[0055] Step 1.1. Obtain historical data for 3 months with an interval of 15 seconds; through mechanism analysis, select the measuring points that have a strong correlation with the vibration of the generator bar as the feature vector. The measuring points include: generator A-phase current, power generation Generator B-phase current, generator C-phase curre...

Embodiment 2

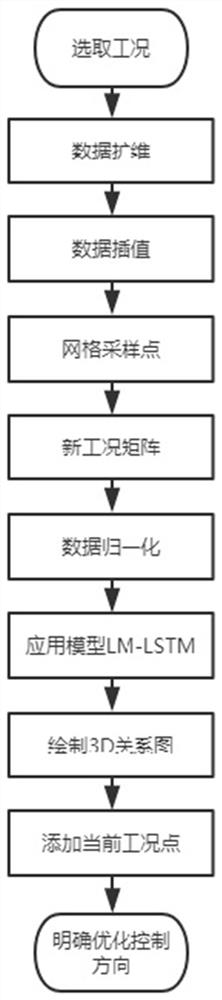

[0083] On the basis of the generator bar vibration LM_LSTM (long short-term memory neural network) model trained in Example 1, the generator bar vibration optimization method is as follows:

[0084] Taking the active power of the generator in the historical data obtained by the plant as the abscissa, and the B-phase radial vibration at the end of the wire rod on the turbine side as the ordinate, draw a scatter diagram to obtain Figure 4 , it can be seen from the figure that when the generator load of the power plant is between 420MW and 630MW, and near 780MW, the B-phase radial vibration at the end of the turbine side bar of the generator easily exceeds the standard value of 250um. Therefore, in this embodiment, the data of three working conditions with unit loads of 480MW, 520MW and 780MW are selected as analysis objects, and the data of working condition 1, working condition 2 and working condition 3 are respectively recorded for optimization analysis.

[0085] Dimensionall...

Embodiment 3

[0095] The method in the above-mentioned embodiment 1 and embodiment 2 can also be used to construct the optimization model of the vibration of the wire rod end of the generator phase A and C, and this method can also input real-time data and output the vibration of the wire rod end of the generator in real time 3D optimization control chart.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com