All-directional sintering process intelligent management and control system

A technology of sintering process and management and control system, which is applied in the field of intelligent management and control system of all-round sintering process, which can solve the problems of lack of data support and inability to accurately adjust the amount of ammonia injection, and achieve the effects of saving use costs, improving efficiency, and facilitating adjustment and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

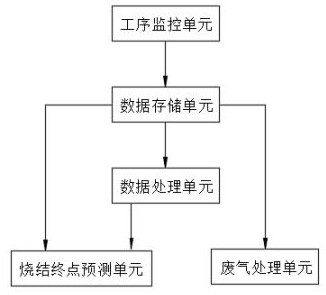

[0026] see figure 1 As shown, the all-round sintering process intelligent management and control system includes a process monitoring unit, a data storage unit, a data processing unit, a sintering end point prediction unit and a waste gas treatment unit;

[0027] The process monitoring unit is used to monitor the whole process of the sintering process. The sintering process is divided into three parts, namely, the batching and distributing process, the ignition and sintering process, and the waste gas treatment process. The process monitoring unit consists of a batching monitoring module, a sintering monitoring module and a waste gas monitoring T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com