Method for adding gas selection function of multifunctional gas sensor and gas sensor

A gas sensor and gas technology, applied in the field of gas sensors, can solve the problems of large temperature control range, cumbersome, time-consuming testing process and data processing, etc., to achieve the effect of improving gas selectivity and expanding types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

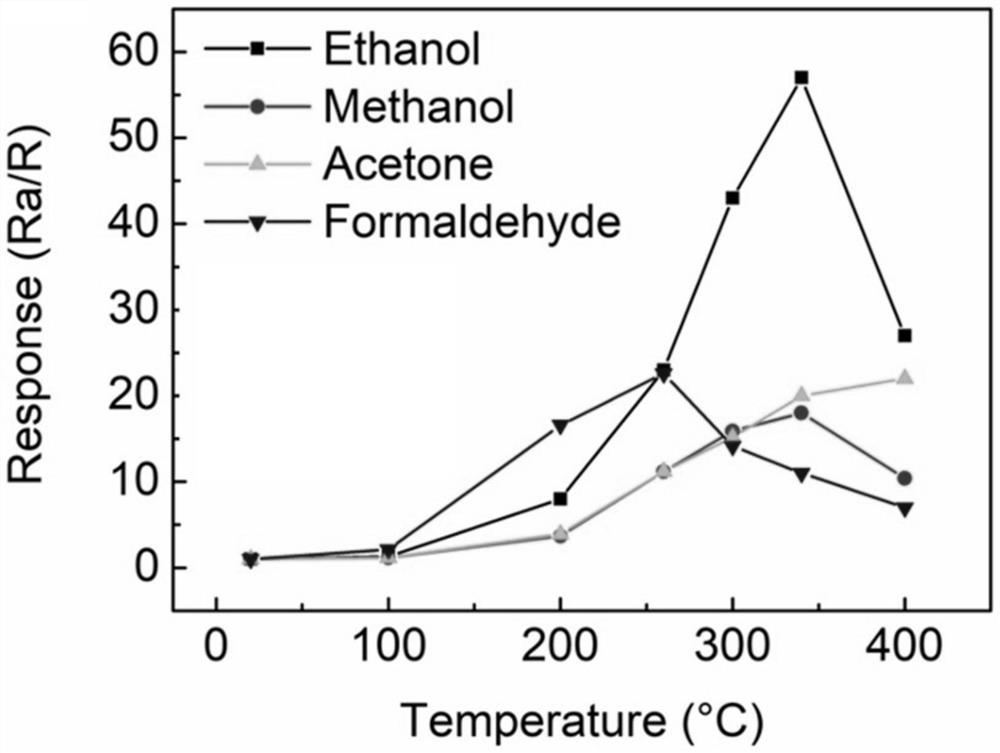

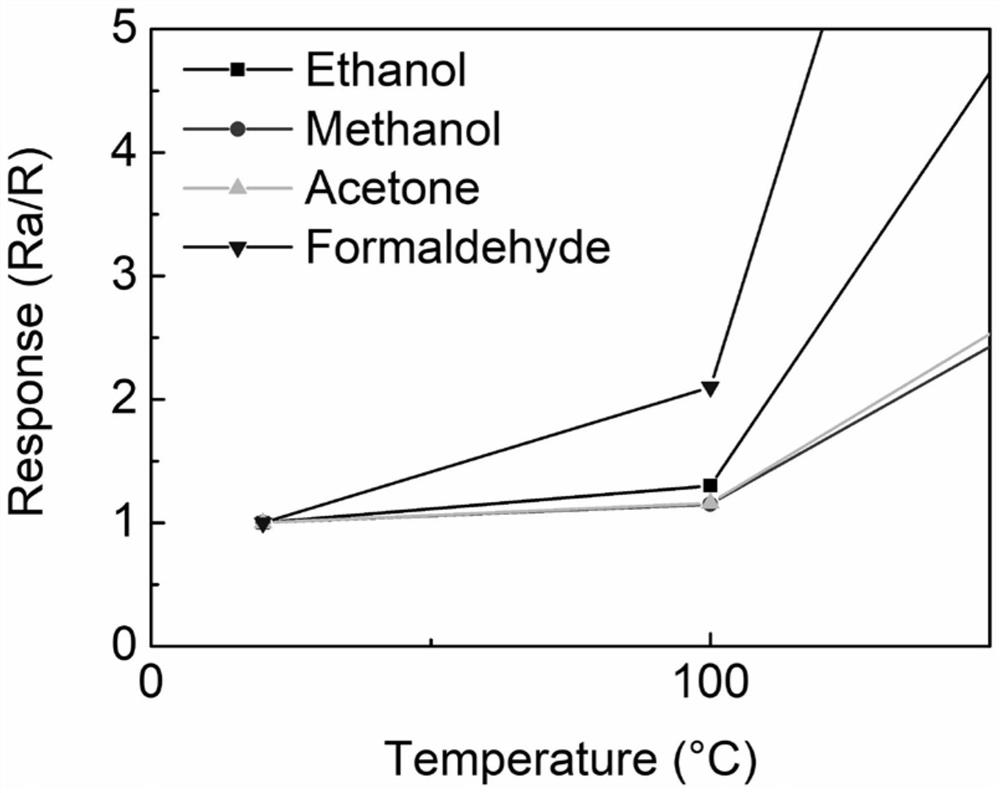

[0057] In this example, nano-tetrapod zinc oxide is used as a semiconductor gas-sensing material, and the effects of nano-gold modification and non-modification on the gas sensor are compared and analyzed. Among them, the gas sensor substrate adopts alumina ceramic tube. The specific test is as follows:

[0058] 1. Preparation of gas sensor

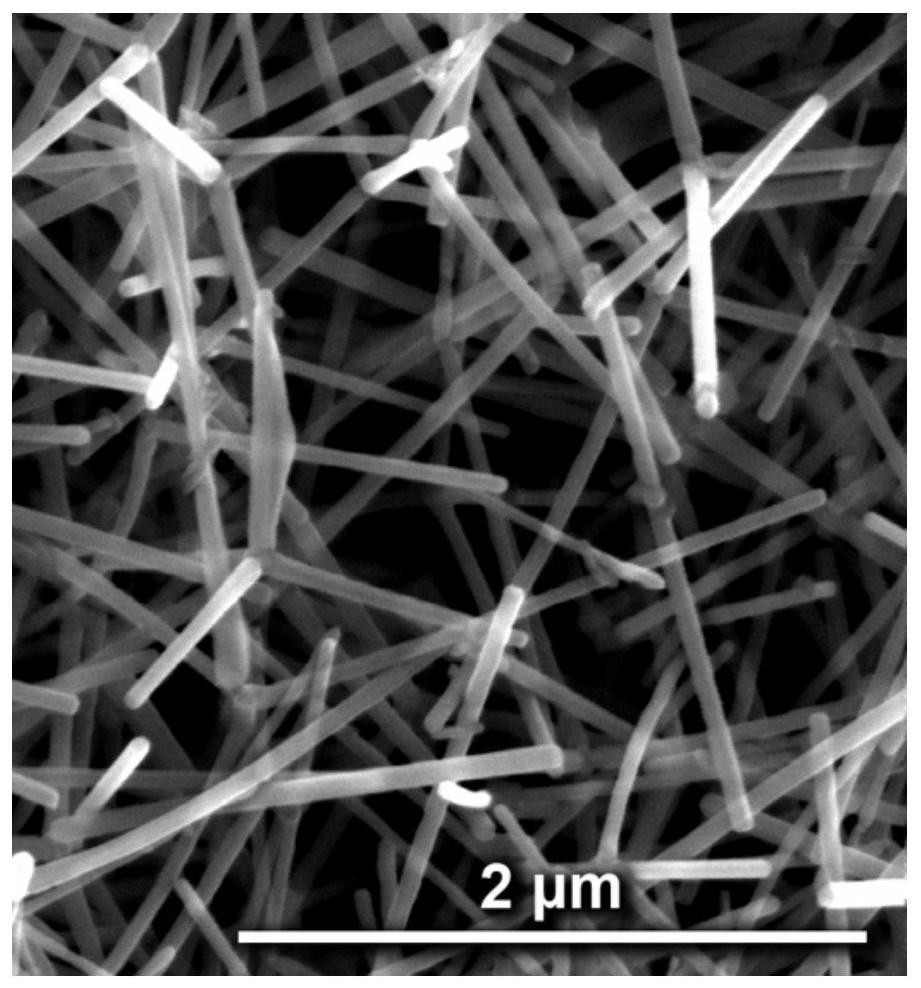

[0059] 1. Preparation of Nano-tetrapod ZnO

[0060] In this example, 1g of zinc sheet is placed in a quartz tube with a length of 10 cm and an inner diameter of 4 mm, and placed in the center of a tube furnace. One end of the tube furnace is fed with 400 sccm of nitrogen, and the other end is fed with 50 sccm of oxygen. The oxygen enters the tube furnace Go through the water before. The central temperature of the tube furnace is 750°C, and it is fired for 20 minutes. At the oxygen inlet end, white flocculent zinc oxide can be collected, that is, nanometer tetrapod zinc oxide can be obtained.

[0061] 2. Preparation of nano-tetrapod Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com