A textile fabric stretching auxiliary part and stretching process

A technology for textile fabrics and auxiliary parts, which is applied in the marking of textile materials, elongation of fabrics, textiles and papermaking, etc. The effect of basic quality assessment, reducing waste, and facilitating rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

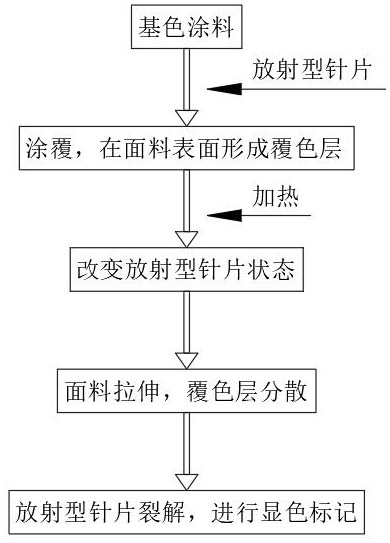

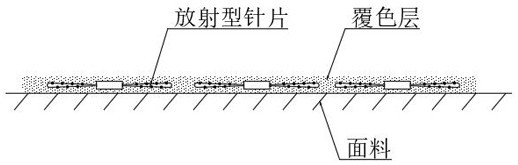

[0040] see figure 1 and figure 2 , a textile fabric stretching process, comprising the following steps:

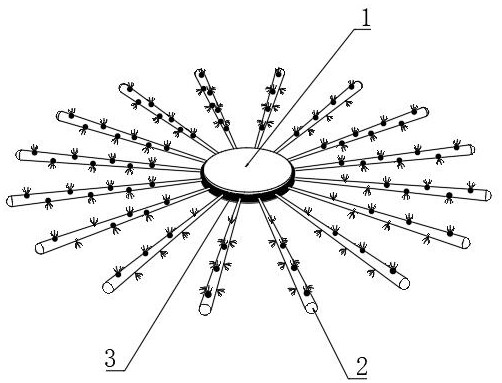

[0041] S1. Evenly apply the base color paint mixed with radial pins on the surface of the fabric to be processed, and form a color coating layer after drying. The base color paint is washable paint;

[0042] S2. Heating the fabric with the color covering layer, the radial needle piece is partially melted by heating, and changes from a fixed state to a crackable state;

[0043] S3. Pull the opposite ends of the fabric to both sides, that is, perform a uniaxial stretching operation on the fabric, and at the same time, the color-covered layer will disperse as the fabric stretches;

[0044] S4. When the fabric is stretched unevenly, the color-coated layer at the over-stretched part will be over-dispersed, causing the radial needle sheet to crack, and the color-developing liquid inside it will overflow, and the part will be marked;

[0045] S5. After the stretching is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com