Preparation method of florfenicol

A technology of florfenicol and auxiliary devices, which is applied in the field of preparation of florfenicol, can solve the problems of no targeted discharge method of hydrogen gas, lack of yield of florfenicol, etc., to facilitate mass processing, convenient and simple operation Extensive, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

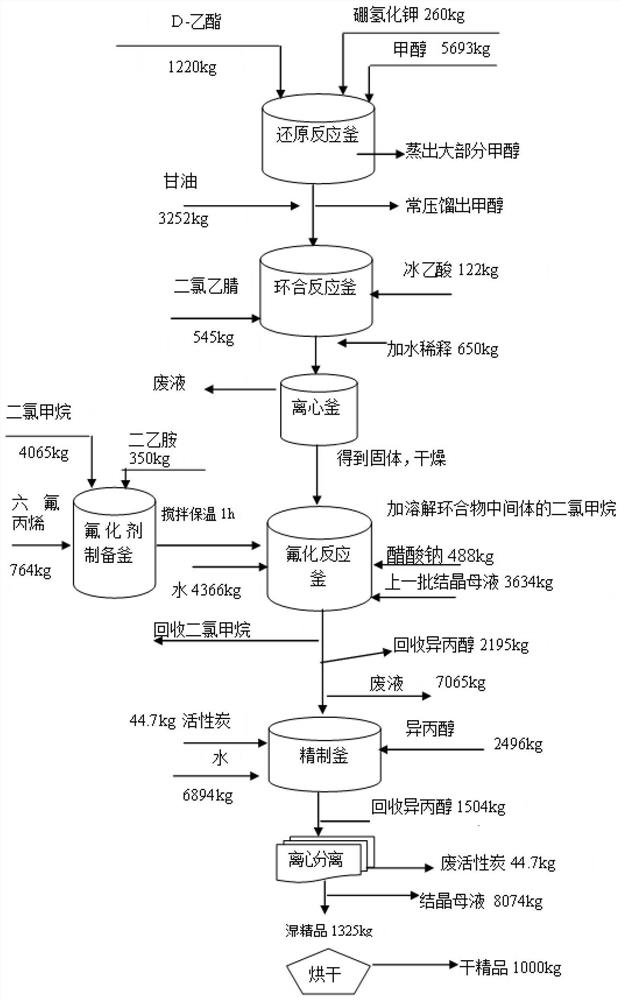

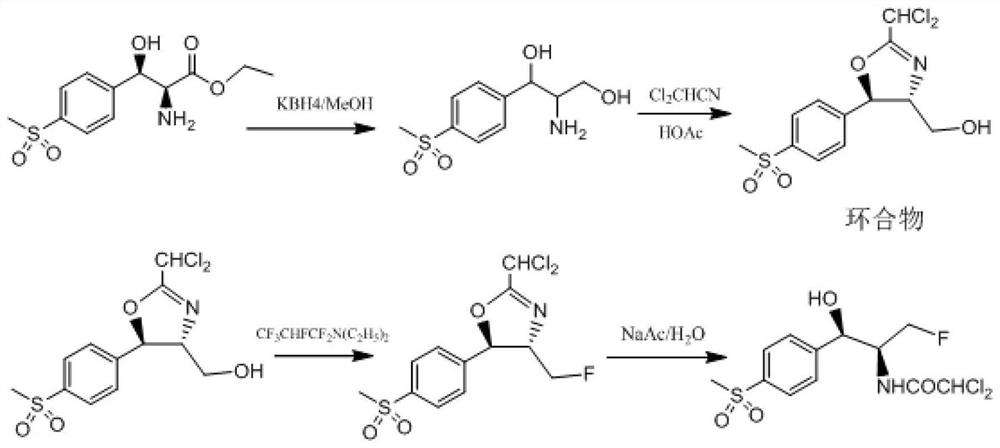

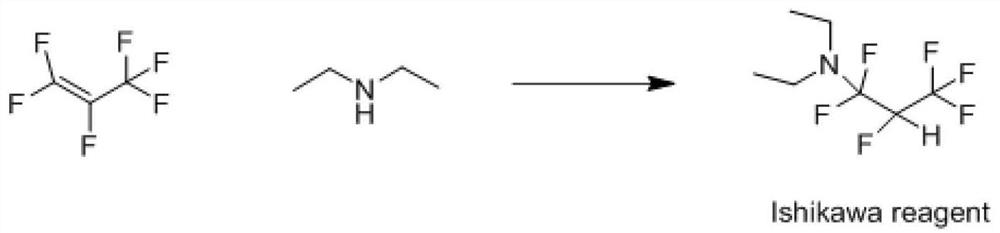

Method used

Image

Examples

Embodiment 1

[0042] The invention claims to protect a feeding auxiliary device for preparing florfenicol, which is characterized in that it includes a reduction reaction kettle 1, an air inlet part 2, an air outlet part 3, a funnel part 4, a crossbar part 5, an ultrasonic device 6, and a left support Part 7, right support part 8.

[0043] The reduction reaction kettle 1 is equipped with an upper port 11, an air inlet 12, an air outlet 13, a feeding port 14, and a stirrer 15, and the upper port 11, the air inlet 12, the air outlet 13, and the feeding port 14 are respectively adapted to the upper Port cover 111, air inlet cover 121, air outlet cover 131, and feed port cover 141; the upper port 11 is located directly above the reduction reaction kettle, and the air inlet 12 and the feed port 14 are located on the inclined surface on the right side of the upper port 11 , the gas outlet 13 is located on the inclined surface on the left side of the upper port 11, and the axis of the feeding port...

Embodiment 2

[0054] (1) Installation and test run steps: remove the upper cover, air inlet cover, and air outlet cover of the reduction reaction kettle, install the air inlet plug and the air outlet plug respectively, and install the air inlet glass tube (23) and Air outlet glass tube (33), and connect the air intake pipe (21), air intake pump (22) and air outlet pipe (31), air outlet pump (32) respectively, cover the upper mouth cover (111), use the air inlet part with 1.4 -1.6L / min speed into the nitrogen, and use the gas outlet to export the gas at the same speed, open and close the upper port repeatedly and monitor until the opening and closing will not cause significant changes in air pressure; this step is to ensure the installation, and the second is to ensure the air flow smooth.

[0055] (2) Steps of installing the funnel part: install the left support part and the right support part at the front and back of the funnel part, remove the feeding port cover and replace it with a seal...

Embodiment 3

[0063] (1) Installation and test run steps: remove the upper cover, air inlet cover, and air outlet cover of the reduction reaction kettle, install the air inlet plug and the air outlet plug respectively, and install the air inlet glass tube (23) and Air outlet glass tube (33), and connect the air intake pipe (21), air intake pump (22) and air outlet pipe (31), air outlet pump (32) respectively, cover the upper mouth cover (111), use the air inlet part with 1.4 -1.6L / min speed into the nitrogen, and use the gas outlet to export the gas at the same speed, open and close the upper port repeatedly and monitor until the opening and closing will not cause a significant change in the air pressure;

[0064] (2) Steps of installing the funnel part: install the left support part and the right support part at the front and back of the funnel part, remove the feeding port cover and replace it with a sealing ring, and the sealing ring is tightly set on the feeding port, so that the ring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com