Rotor-free unmanned aerial vehicle

A UAV and rotor technology, applied in the field of UAV, can solve the problems such as the inability of the airflow to be uniformly distributed, the airflow stays for a short time, and the damage to the internal airflow drive device, so as to optimize the flight stability and controllability, and reduce the instantaneous airflow. The effect of flow velocity and suppression of airflow shock jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

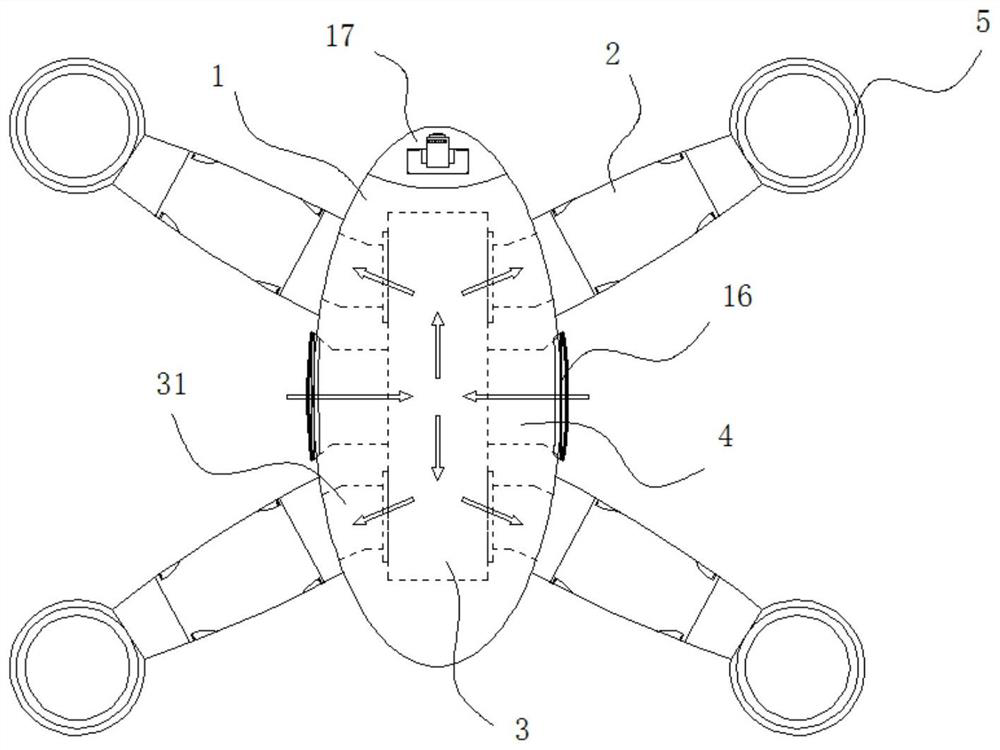

[0037] see figure 1, the invention provides a technical solution: a UAV without rotors, including a fuselage body 1 and four sets of arms 2 arranged around the fuselage body 1 in a ring, and an air intake chamber 3 is arranged inside the fuselage body 1 , the intake chamber 3 has an air inlet 4 connected to both sides of the fuselage body 1, the machine arm 2 is a hollow pipe structure, and the inner end of the machine arm 2 is respectively connected to the air intake chamber 3 through a soft air pipe 31, the machine arm The outer ends of the arms 2 are respectively connected with air jet rings 5 , and each of the four sets of arms 2 is provided with a turbofan 7 driven by a servo motor 6 . When the UAV is working, the four groups of servo motors 6 inside the arms 2 drive the turbofan 7 to rotate at high speed, and the external air is sucked in through the air inlets 4 on both sides of the fuselage. The inner cavity forms an airflow with a certain high flow rate, and the hi...

Embodiment 2

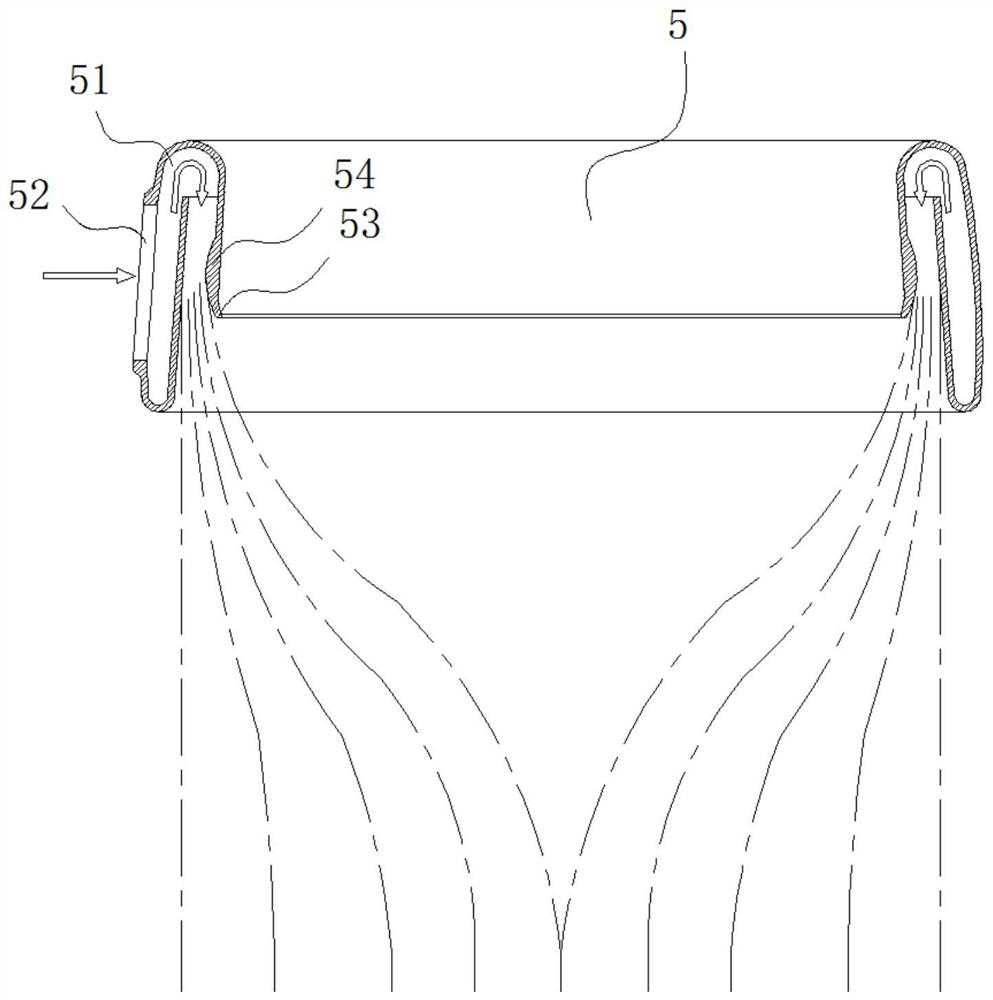

[0039] see figure 2 , on the basis of Embodiment 1, the airflow injection ring 5 is an integrally formed annular structure formed by bending the upper and lower ends of a cylindrical structure with different bending radii to the inner side of the cylinder for 180°. A U-shaped guide channel 51 is formed inside the jet ring 5, and a jet air inlet 52 is provided at the connection between the U-shaped guide channel 51 and the outer end of the machine arm 2, and the annular air outlet port 53 of the U-shaped guide channel 51 is located at the airflow injection ring 5. The middle part of the inner cavity is set in the shape of a horn with rounded corners; since the U-shaped flow guide channel 51 is formed inside the airflow injection ring 5, the air flow has a process of reversing after passing through the U-shaped flow guide channel 51 after being introduced by the machine arm 2. , in the process of airflow reversing at the same time, the circumferential uniform distribution is ca...

Embodiment 3

[0041] see Figure 3-4 , on the basis of Embodiment 1, the middle part of the machine arm 2 is a detachable installation section 21, and the two ends of the installation section 21 are connecting flange ends 22 with screw holes, and the inner wall of the installation section 21 is provided with a The extension arm 23 of 6, the inner and outer sides of the servo motor 6 and the turbofan 7 in the adjacent two groups of arms 2 are installed in the opposite direction, so as to offset the reaction torque of the drone during flight and avoid the drone from appearing during the flight. spin case; further, see Figure 5 , the extension arm 23 is provided with three groups distributed in a ring, and a fan-shaped airflow channel is formed between the extension arm 23 and the extension arm 23, which is used to circulate high air flow. The three groups of extension arms 23 are distributed in a spoke-like ring to ensure a stable connection structure At the same time, the number of extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com