Anti-icing and de-icing composite material with electric heating/super-hydrophobic function and preparation method of anti-icing and de-icing composite material

A composite material and super-hydrophobic technology, applied in the field of anti-icing composite materials and preparation, can solve the problems of reducing the electrical conductivity and thermal conductivity of graphene paper, affecting the electrical and thermal properties of materials, and unstable microstructure strength, and achieving high anti-icing efficiency. , The distribution of microstructure is uniform, and the effect of increasing plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

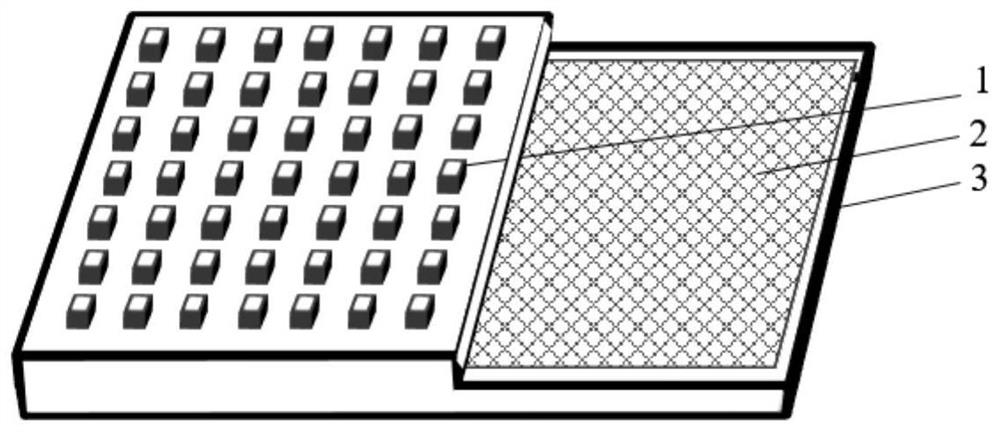

[0041] This embodiment relates to an anti-icing composite material with electric heating / superhydrophobic function, see image 3 Shown; include: from top to bottom are super-hydrophobic layer 1, electric heating grid layer 2 and base layer 3;

[0042] in,

[0043] The electric heating grid layer 2 is a mesh metal template with a micropore array; the electric heating grid layer 2 is covered in the base layer 3;

[0044] The base layer 3 is made of polymer mixture.

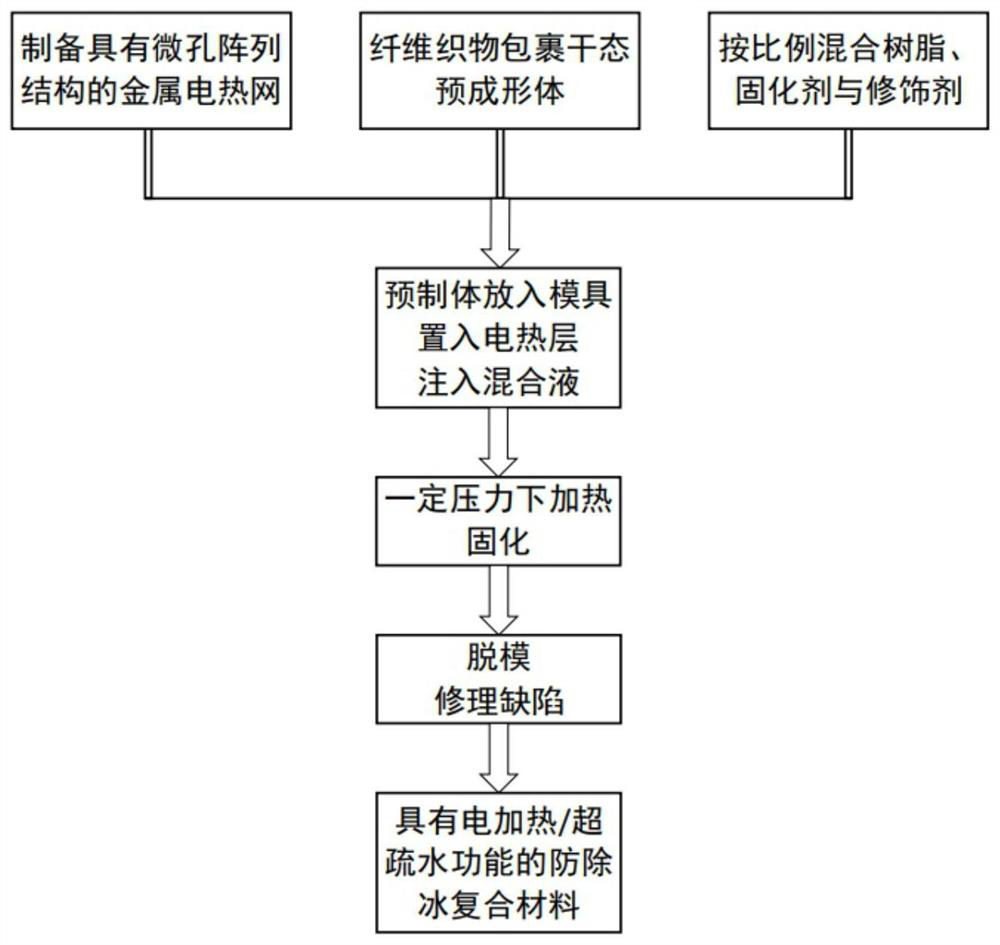

[0045]This embodiment also relates to the preparation method of the aforementioned anti-icing composite material with electric heating / superhydrophobic function, see figure 1 Shown: Include the following steps:

[0046] Select high-purity aluminum plate as the raw material of the electric heating layer, cut it into a square thin material with a size of 50*50*1mm, and anneal it at 450°C for 3 hours to remove the internal stress introduced by cold rolling and mechanical processing and form an orderly recrystallized...

Embodiment 2

[0056] This embodiment relates to an anti-icing composite material with electric heating / superhydrophobic function, see image 3 Shown; include: from top to bottom are super-hydrophobic layer 1, electric heating grid layer 2 and base layer 3;

[0057] in,

[0058] The electric heating grid layer 2 is a mesh metal template with a micropore array; the electric heating grid layer 2 is covered in the base layer 3;

[0059] The base layer 3 is made of polymer mixture.

[0060] This embodiment also relates to a preparation method of an anti-icing composite material with electric heating / superhydrophobic function, see figure 1 Shown: Include the following steps:

[0061] Select high-purity copper plate as the raw material of the electric heating layer, cut it into a square thin material with a size of 40*40*1mm, and anneal it at 600°C for 2 hours to remove the internal stress introduced by cold rolling and mechanical processing and form an orderly recrystallized crystal grain.

...

Embodiment 3

[0071] This embodiment relates to an anti-icing composite material with electric heating / superhydrophobic function, see image 3 Shown; include: from top to bottom are super-hydrophobic layer 1, electric heating grid layer 2 and base layer 3;

[0072] in,

[0073] The electric heating grid layer 2 is a mesh metal template with a micropore array; the electric heating grid layer 2 is covered in the base layer 3;

[0074] The base layer 3 is made of polymer mixture.

[0075] This embodiment also relates to the preparation method of the aforementioned anti-icing composite material with electric heating / superhydrophobic function, see figure 1 Shown: Include the following steps:

[0076] 310s stainless steel is selected as the raw material of the electric heating layer, cut into square thin materials with a size of 40*40*1mm, and annealed at 450°C for 3 hours to remove the internal stress introduced by cold rolling and mechanical processing and form orderly recrystallized grains ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com