Adjustable ultra-high pressure water jet cutting device and using method

A cutting device and ultra-high pressure technology, applied in metal processing and other directions, can solve the problems of insignificant pressure relief and anti-reflection effect, narrow cutting slot width, difficult to effectively cut coal and rock, etc. The effect of reducing the number of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The details of the present invention and the specific implementations thereof will be further described below with reference to the accompanying drawings and specific embodiments.

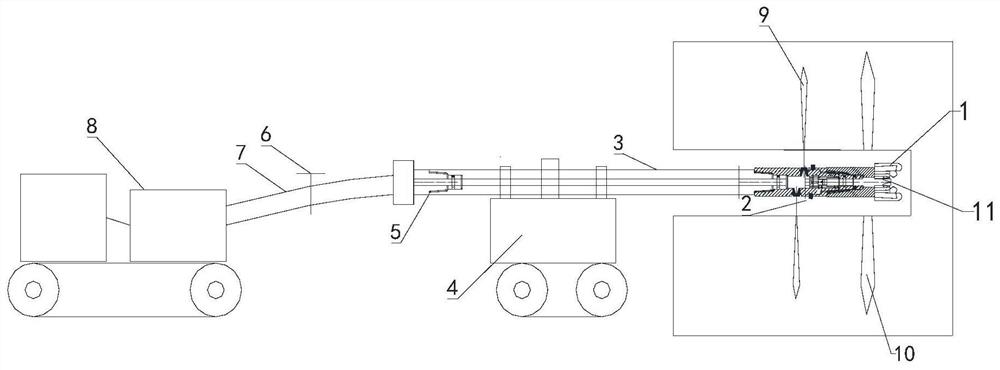

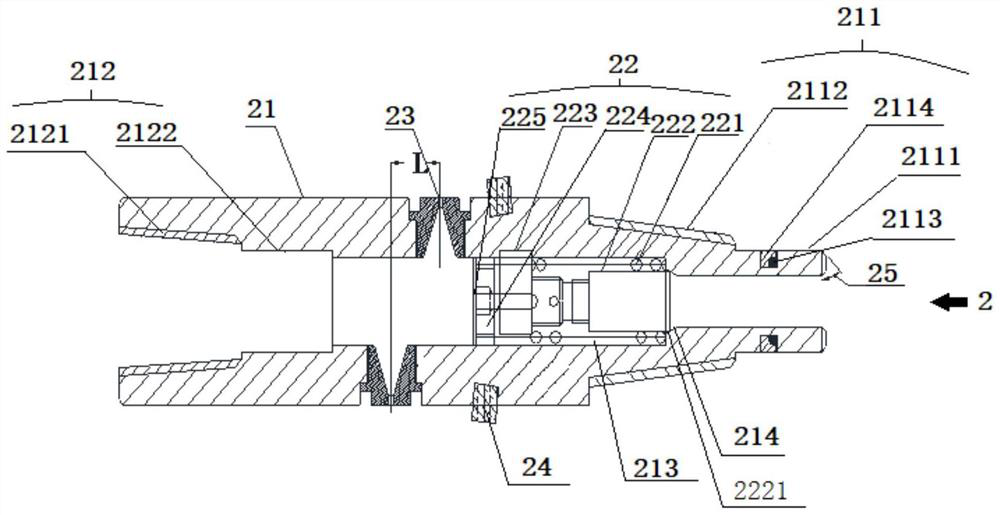

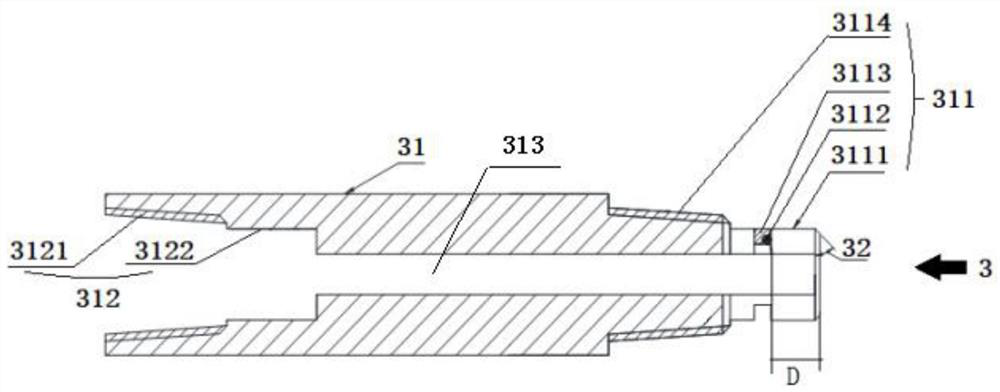

[0035] refer to figure 1 , an adjustable ultra-high pressure water jet cutting device, the device includes a drill bit 1, an ultra-high pressure fluid pressure conversion device 2, an ultra-high pressure sealed drill pipe 3, an ultra-high pressure rotating water tail 5, a plurality of ultra-high pressure Hose 6 and ultra-high pressure hydraulic pump station 8; the ultra-high pressure sealing drill pipe 3 is installed on the drilling rig 4 and is driven by the rotary device on the drilling rig 4 to rotate and feed, and a pressure relief is installed between the ultra-high pressure hoses 7 The regulating valve 7, the ultra-high pressure fluid pressure conversion device 2 and the ultra-high pressure sealing drill pipe 3, the ultra-high pressure sealing drill pipe 3 and the ultra-high pressure r...

Embodiment 2

[0049] refer to figure 1 , the present invention also provides a method of using an adjustable ultra-high pressure water jet cutting device, and the specific implementation steps are as follows:

[0050] (1) The ultra-high pressure sealing drill pipe 3 is installed on the drilling rig 4 and is driven by the rotary device on the drilling rig to rotate and feed, and the ultra-high pressure fluid pressure conversion device 2 is installed on the front end of the ultra-high pressure sealing drill pipe 3; the ultra-high pressure fluid pressure conversion The drill bit 1 is installed at the front end of the device; a plurality of ultra-high pressure hoses 6 are connected to the ultra-high pressure sealing drill pipe 3 through the ultra-high pressure rotating water tail 5; the pressure relief regulating valve 7 is installed between the ultra-high pressure hoses 6, and the ultra-high pressure hydraulic pump station 8 passes through The ultra-high pressure hose 6 and the ultra-high pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com