Adjustable ultrahigh-pressure water jet cutting device and using method

A cutting device and ultra-high pressure technology, applied in the direction of metal processing, etc., can solve the problems of difficult effective cutting of coal and rock, narrow cutting slot width, and inconspicuous effect of pressure relief and anti-reflection, etc., so as to reduce the number of loading and unloading, smooth installation, and practical The effect of the operation effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings and specific embodiments.

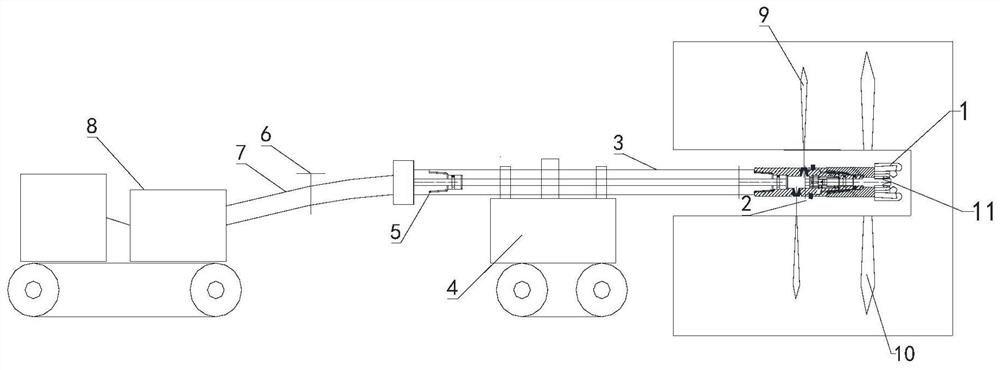

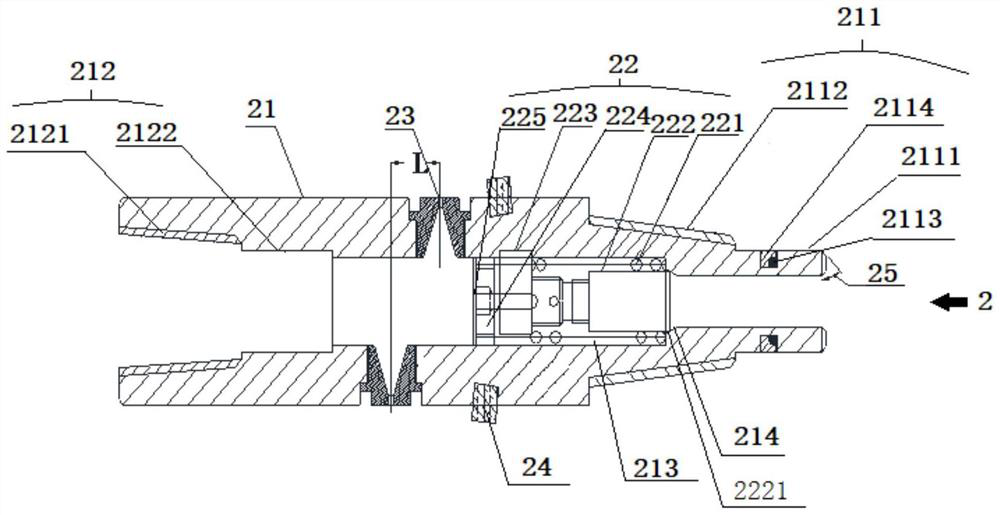

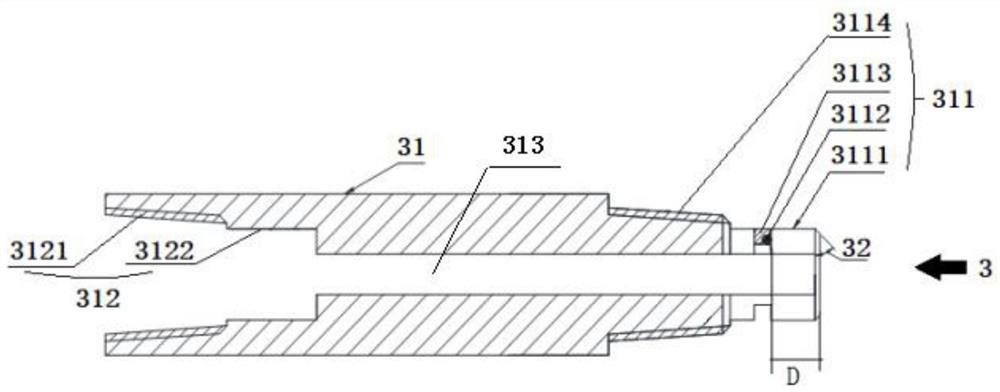

[0035] refer to figure 1 , an adjustable ultra-high pressure water jet cutting device, which includes a drill bit 1 connected in sequence from front to back, an ultra-high pressure fluid pressure conversion device 2, an ultra-high pressure sealed drill pipe 3, an ultra-high pressure rotating water tail 5, and multiple ultra-high pressure Hose 6 and ultra-high pressure hydraulic pumping station 8; the ultra-high pressure sealed drill pipe 3 is installed on the drilling rig 4 and driven by the rotary device on the drilling rig 4 to rotate and feed, and a pressure relief device is installed between the ultra-high pressure hose 7 The regulating valve 7, the ultra-high pressure fluid pressure conversion device 2 and the ultra-high pressure sealed drill pipe 3, and the ultra-high pressure sealed...

Embodiment 2

[0049] refer to figure 1 , the present invention also provides a method for using an adjustable ultra-high pressure water jet cutting device, the specific implementation steps are as follows:

[0050] (1) The ultra-high pressure sealed drill pipe 3 is installed on the drilling rig 4 and driven by the rotary device on the drilling rig to rotate and feed, and the ultra-high pressure fluid pressure conversion device 2 is installed at the front end of the ultra-high pressure sealed drill pipe 3; the ultra-high pressure fluid pressure conversion A drill bit 1 is installed at the front end of the device; multiple ultra-high pressure hoses 6 are connected behind the ultra-high pressure sealed drill pipe 3 through an ultra-high pressure rotating water tail 5; The ultra-high pressure hose 6 and the ultra-high pressure rotating water tail 5 supply water to the ultra-high pressure sealed drill pipe 3, the ultra-high pressure fluid pressure replacement device 2 and the drill bit 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com