Application of cyclic hardening model based on weld dislocation entanglement in welded joint fatigue life prediction

A technology for fatigue life prediction and welded joints, which is applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems of fatigue fracture in the center of the weld and the inability to explain the microscopic mechanism, etc., and achieve reliable results, convenient operation, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059]The new heat-resistant steel Sanicro 25 steel pipe is selected as the base material, and the Sanicro 25 steel pipe is butted by manual tungsten argon arc welding. A low cycle fatigue test with a total strain amplitude of 0.4% was performed on the welded joints at 700°C. For specific experimental procedures, please refer to the literature "Low cycle fatigue behavior and microstructure evolution of novel 9Cr–3W–3Co tempered martensitic steel at 650℃" (Jing H, Luo Z, Xu L, etal. Materials Science & Engineering A, 2018, 731.) record is carried out.

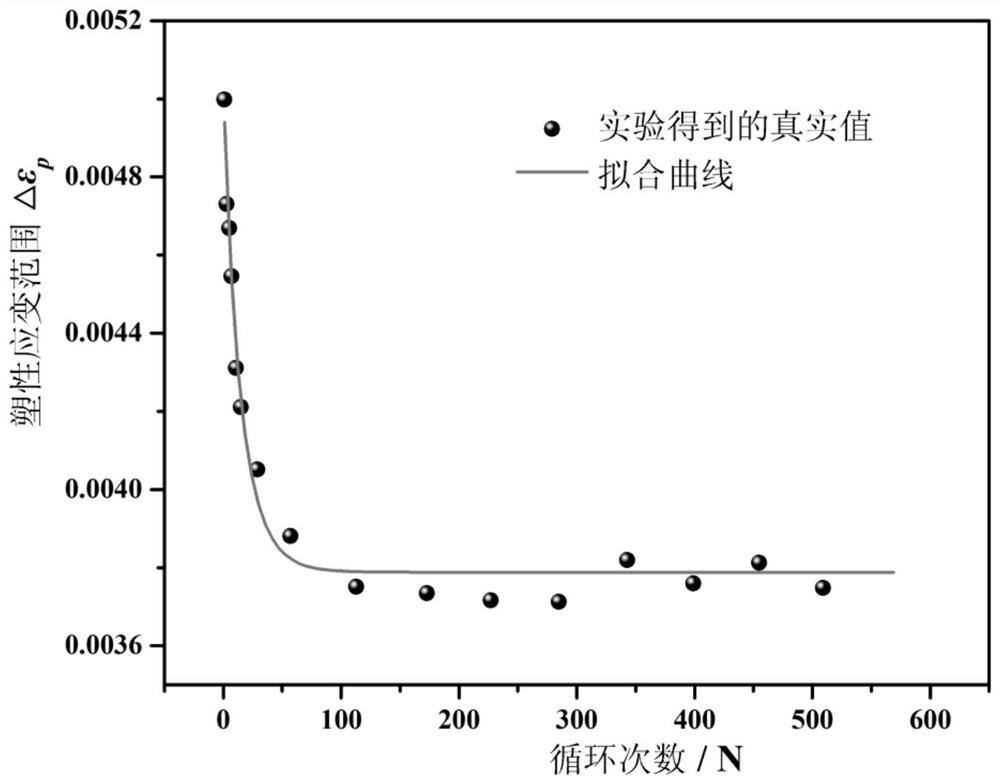

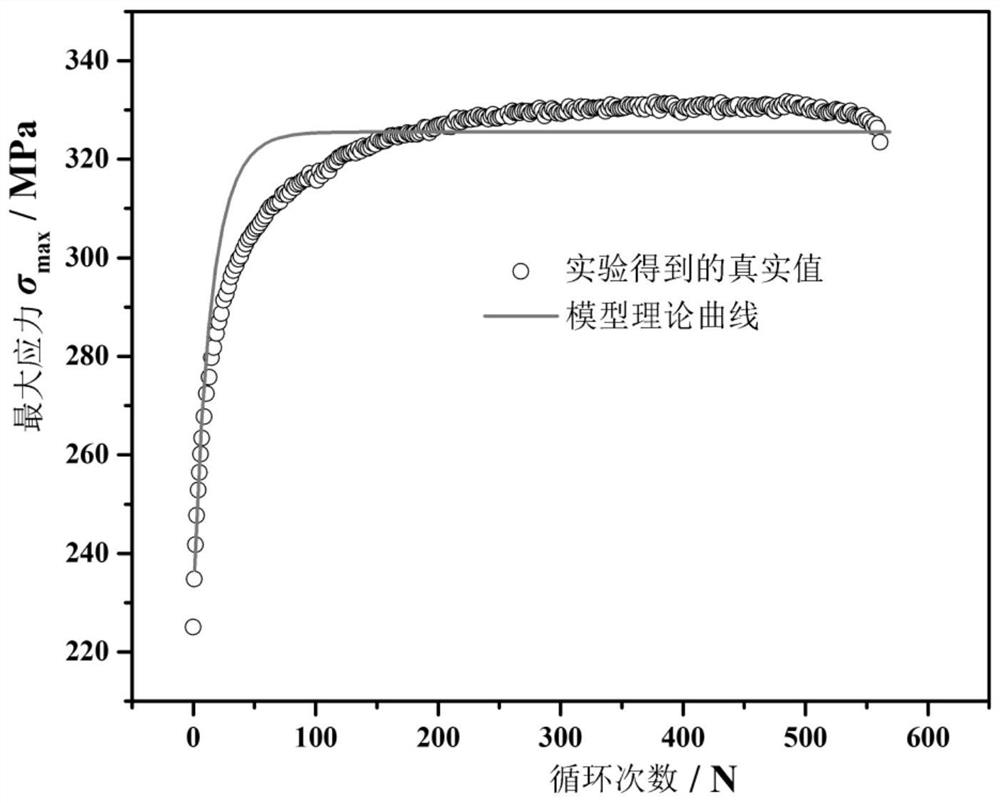

[0060] Then, according to the obtained experimental data, the plastic strain range Δε under different cycles N is obtained p value. Then use the above formula (14) to fit N and Δε p The value of , the fitting result is as follows figure 1 shown.

[0061] Therefore, formula (14) can be determined as:

[0062]

[0063] According to the experimental parameters, Δε t = 0.008 and E = 154.6 GPa. Put formula (S1), Δε t and ...

Embodiment 2

[0067] 316H austenitic stainless steel welded joints are selected as the verification object. For welded joints at 550°C and a strain rate of 1 x 10 -3 the s -1 Low cycle fatigue tests were performed with a total strain amplitude of 0.5%. For specific experimental procedures, refer to the literature "Low cyclefatigue behavior and microstructure evolution of a novel 9Cr–3W–3Co tempered martensitic steel at 650°C" (Jing H, Luo Z, Xu L, et al. Materials Science & Engineering A, 2018, 731.) Recording is carried out.

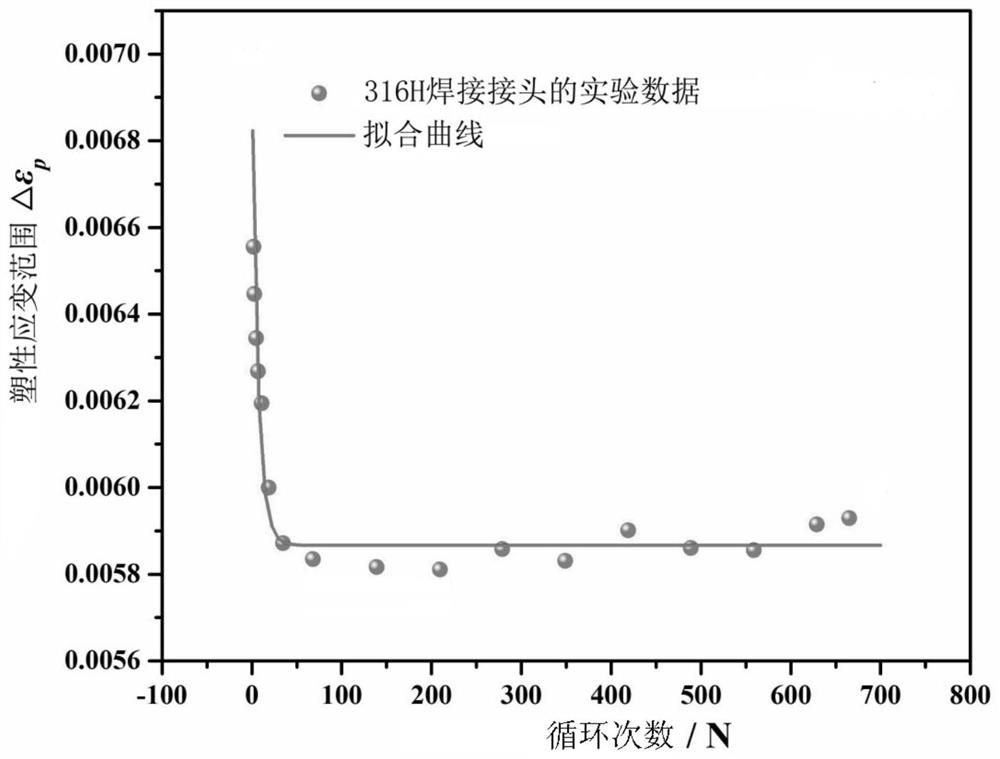

[0068] Then, according to the obtained experimental data, the plastic strain range Δε under different cycles N is obtained p value. Then use the above formula (14) to fit N and Δε p The value of , the fitting result is as follows image 3 shown.

[0069] Therefore, formula (14) can be determined as:

[0070]

[0071] According to the experimental parameters, Δε t = 0.01 and E = 163.33 GPa. The formula (S3), Δε t and E are brought into the above formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com