Omnibearing analyzing and solving method for jump problem of contactor

A solution, contactor technology, applied in sequence/logic controller program control, instrument, program control, etc., can solve the problems of personal casualties, explosion accidents, etc., achieve less investment, ensure stability, and quick results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The comprehensive analysis and solution method for the contactor anti-jumping problem of the present invention will be further described in detail below in conjunction with the accompanying drawings.

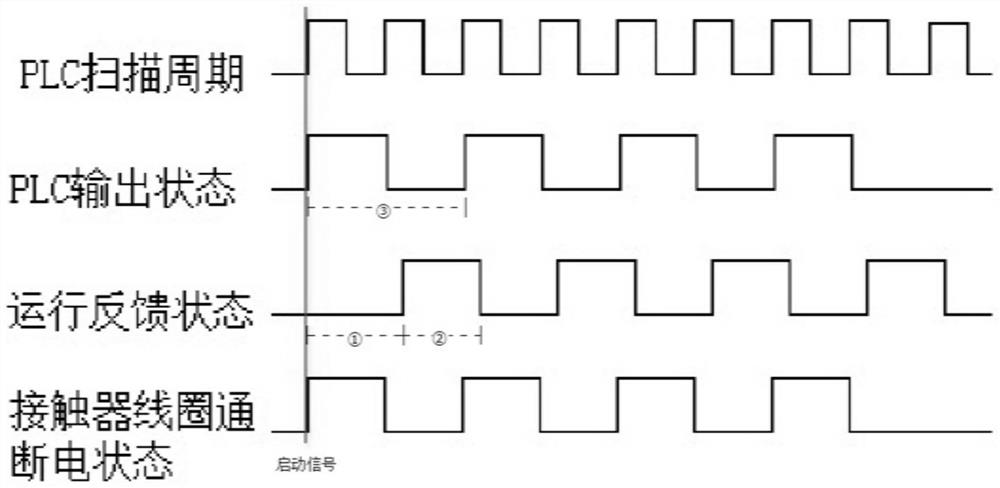

[0021] Such as figure 1 As shown, it is a schematic diagram of overlapping curves between the program scanning period and the motor operation reverse sequence in the present invention.

[0022] From figure 1 It can be seen from the figure that if the scan period in the on-site PLC program is set to 200MS, when the start signal comes, the motor running feedback signal is transmitted to the PLC by the normally open contact of the relay. There will be a delay closure. When the delay time is greater than 200MS and less than 300MS, the feedback signal received by the PLC will be delayed and turned into "1" at the same time, as shown in Figure ①, and the output of the PLC will be turned from "1" to "0" state output . When the next scan cycle comes, although the relay receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com