Method for measuring multiple heavy metals in surface water by co-plating mercury film

A measurement method, surface water technology, applied in the direction of material electrochemical variables, etc., can solve problems such as low oxidation potential, influence on Cu measurement, and inaccurate detection of metal elements, so as to reduce test time and discharge volume, and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

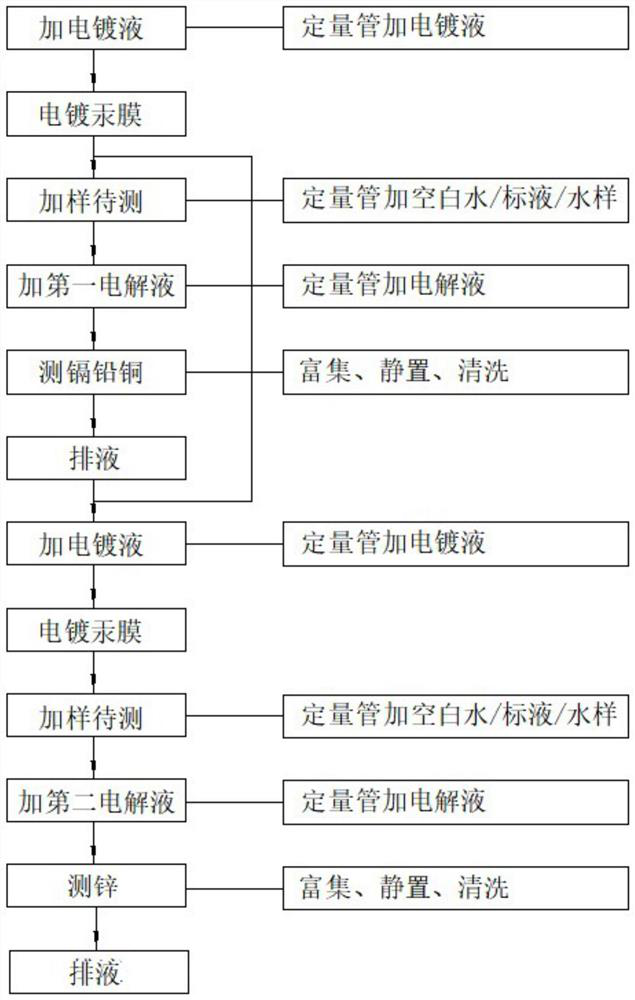

[0028] A method for measuring mercury co-plating films of multiple heavy metals in surface water, comprising the following steps:

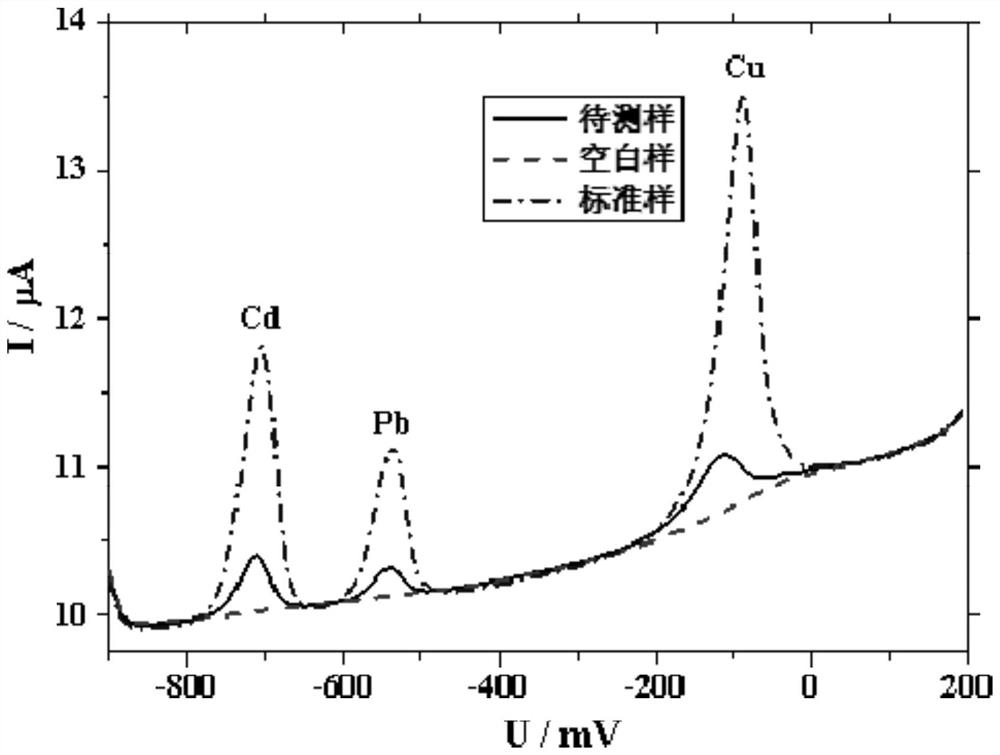

[0029] S1. Mix pure water with a volume ratio of 1:1 and the first electrolyte and add it to the measuring cell. The first electrolyte is CH 3 COOH-CH 3 COONa buffer and Hg(NO 3 ) 2 The mixed solution, the pH of the first electrolyte is 3, where Hg 2+ The concentration is 0.01g / L, insert working electrode, reference electrode and counter electrode, working electrode, reference electrode and counter electrode are connected to control potentiometer by wire, and described working electrode is conductive ITO electrode; Reference electrode can be Saturated calomel electrode, the counter electrode is a platinum sheet electrode, enriched at a constant potential of -1.2 to -0.9V for 1 to 3min, and then applied a positive potential in the range of -0.9 to 0.2V to scan the dissolution response signal to obtain the blank solution at A graph of the peak c...

Embodiment 2

[0036] A method for measuring mercury co-plating films of multiple heavy metals in surface water, comprising the following steps:

[0037] S1. Mix pure water with a volume ratio of 9:1 and the first electrolyte and add it to the measuring cell. The first electrolyte is CH 3 COOH-CH 3 COONa buffer and Hg(NO 3 ) 2 The mixed solution, the pH of the first electrolyte is 6, where Hg 2+ The concentration is 5.0g / L, inserts working electrode, reference electrode and counter electrode, and working electrode, reference electrode and counter electrode are connected to control potentiometer by wire, and described working electrode is glassy carbon electrode; Reference electrode can be Silver / silver chloride electrode, the counter electrode is a platinum sheet electrode, enriched at a constant potential of -1.2 to -0.9V for 1 to 3 minutes, and then applied a positive potential in the range of -0.9 to 0.2V to scan the dissolution response signal to obtain a blank solution A graph of th...

Embodiment 3

[0044] A method for measuring mercury co-plating films of multiple heavy metals in surface water, comprising the following steps:

[0045] S1. Mix pure water with a volume ratio of 6:1 and the first electrolyte and add it to the measuring cell. The first electrolyte is CH 3 COOH-CH 3 COONa buffer and Hg(NO 3 ) 2 The mixed solution, the pH of the first electrolyte is 4.5, where Hg 2+ The concentration is 2.0g / L, insert working electrode, reference electrode and counter electrode, working electrode, reference electrode and counter electrode are connected to control potentiometer by wire, and described working electrode is glassy carbon electrode; Reference electrode can be Silver / silver chloride electrode, the counter electrode is a platinum sheet electrode, enriched at a constant potential of -1.2 to -0.9V for 1 to 3 minutes, and then applied a positive potential in the range of -0.9 to 0.2V to scan the dissolution response signal to obtain a blank solution A graph of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com