Method for adding and repairing thermal insulation layer of old community house

A technology of insulation layer and residential area, which is applied in the direction of insulation, building maintenance, building components, etc., can solve the problems of insulation layer falling off, no insulation layer installed, etc., and achieve the effect of firm connection and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

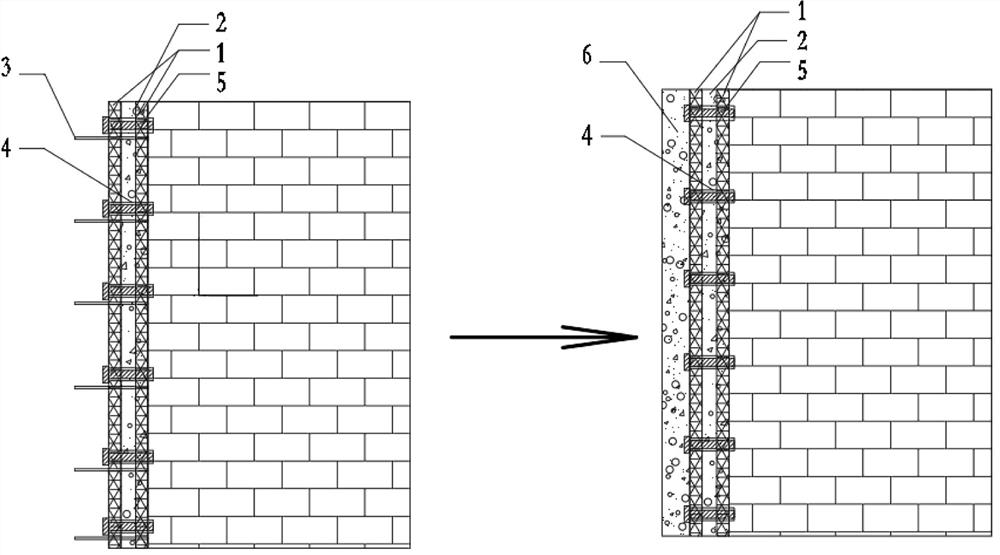

[0049] see Figure 1-6 , a method for installing and repairing thermal insulation layers of houses in old communities, comprising the following steps:

[0050] Step 1.1, clean up the wall to be repaired, after cleaning the wall, use an angle grinder to roughen the wall;

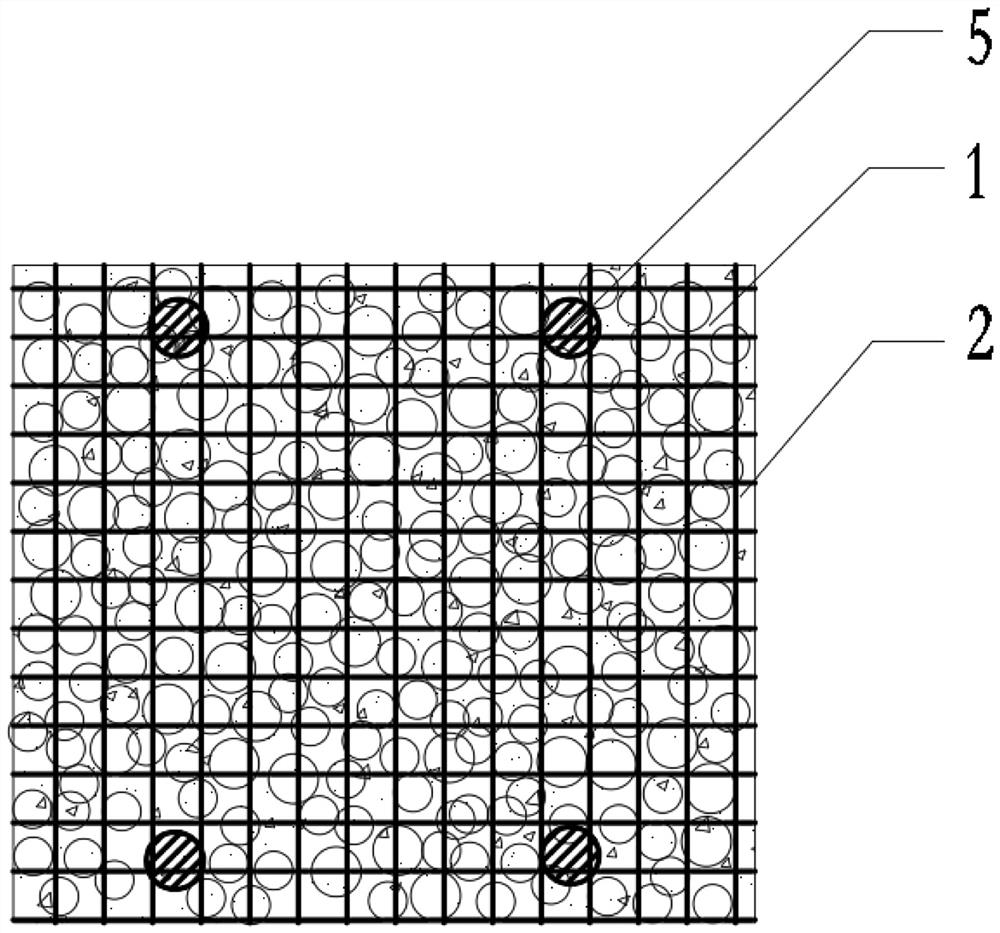

[0051] Step 1.2, setting one or more layers of ceramsite layer 2 between the interlayers of two layers of steel mesh 1 and making it into an insulation layer;

[0052] Step 1.3, laminating and fixing the prepared insulation layer on the wall;

[0053] Step 1.4, drill a hole larger than the diameter of the magnetic rivet at the connection between the insulation layer and the wall, insert a thin air duct 3 into the hole, and then insert the magnetic rivet 5 adhered with the magnetic expansion mortar 4 into the hole;

[0054] Step 1.5, after all the magnetic rivets 5 are inserted, pull out the thin airway 3;

[0055] Step 1.6, spraying concrete 6 containing porous substances on the outer surface of the insula...

Embodiment 2

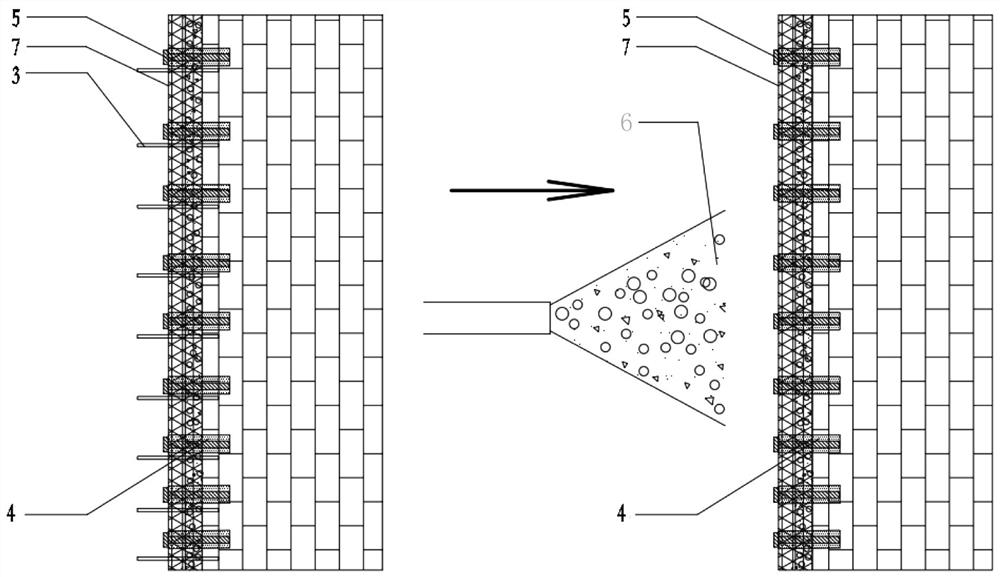

[0058] A method for installing and repairing thermal insulation layers of houses in old communities, comprising the following steps:

[0059] Step 2.1, clean up the wall to be repaired, after cleaning the wall, use an angle grinder to roughen the wall;

[0060] Step 2.2, using multi-layer steel mesh 1 to make multiple grids 7 with a certain thickness;

[0061]Step 2.3, drill a hole larger than the diameter of the magnetic rivet at the four corners of each grid 7, drill a hole larger than the magnetic rivet at the corresponding position of the wall, insert the thin air duct 3, and then insert the A magnetic rivet 5 adhered with magnetic expansion mortar 4 is inserted into the hole;

[0062] Step 2.4, after all the magnetic rivets 5 are inserted, pull out the thin airway 3;

[0063] Step 2.5, after the grid 7 is fixed, the concrete 6 containing the porous material is sprayed into the grid 7 by spraying.

[0064] By adopting the above-mentioned repair method, the multi-layer g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com