Multilayer water-based coating and spraying method thereof

A water-based paint and water-based technology, applied in the field of paint, can solve problems such as poor adhesion and excessive drying temperature, and achieve the effect of smooth hand feeling, increased smoothness, and easy rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

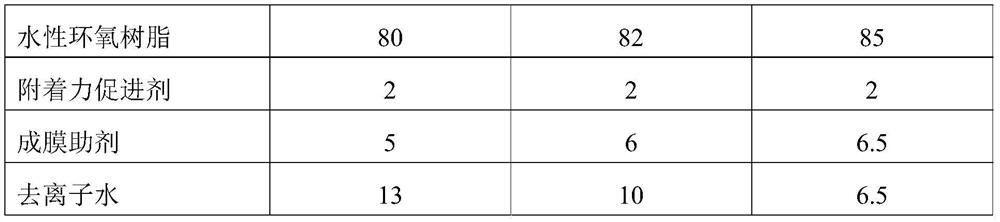

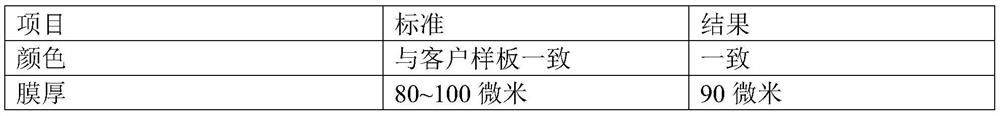

[0029] The invention provides a multi-layer water-based paint, which specifically includes a primer, a middle paint and a top paint. The primer is two-component, including A-component and B-component. Among them, component A uses water-based epoxy resin as the main resin, and component B uses water-based polyamide resin as the main resin. When using, first mix the two components, and then spray them on the surface of the workpiece. The amide resin supplemented with an adhesion promoter can undergo a chain reaction at a lower temperature and cure to form a primer layer. The primer layer has good adhesion to plastic materials and metal materials, and has good resistance Acid and alkali resistance, water boiling resistance, salt spray resistance, and strong covering ability, can cover plastic and hardware joints, easy to polish, easy to rework. A water-based epoxy resin with a high epoxy equivalent and more than 10 secondary hydroxyl groups is preferred, which is more conducive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com