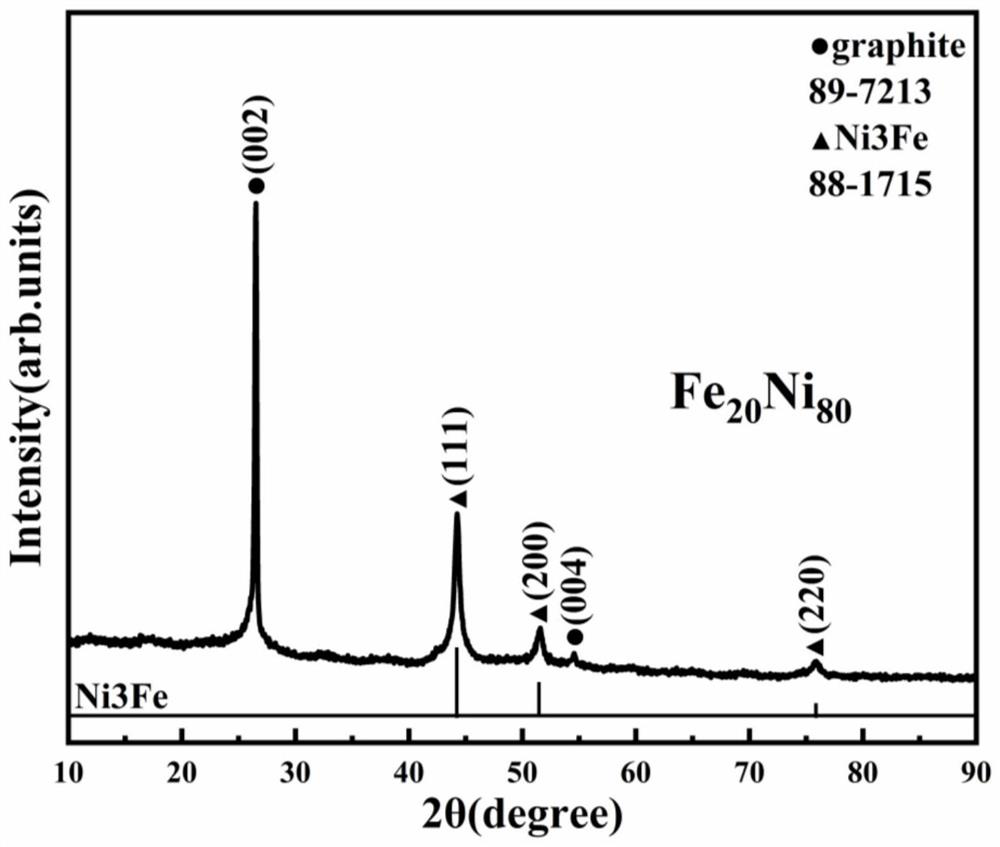

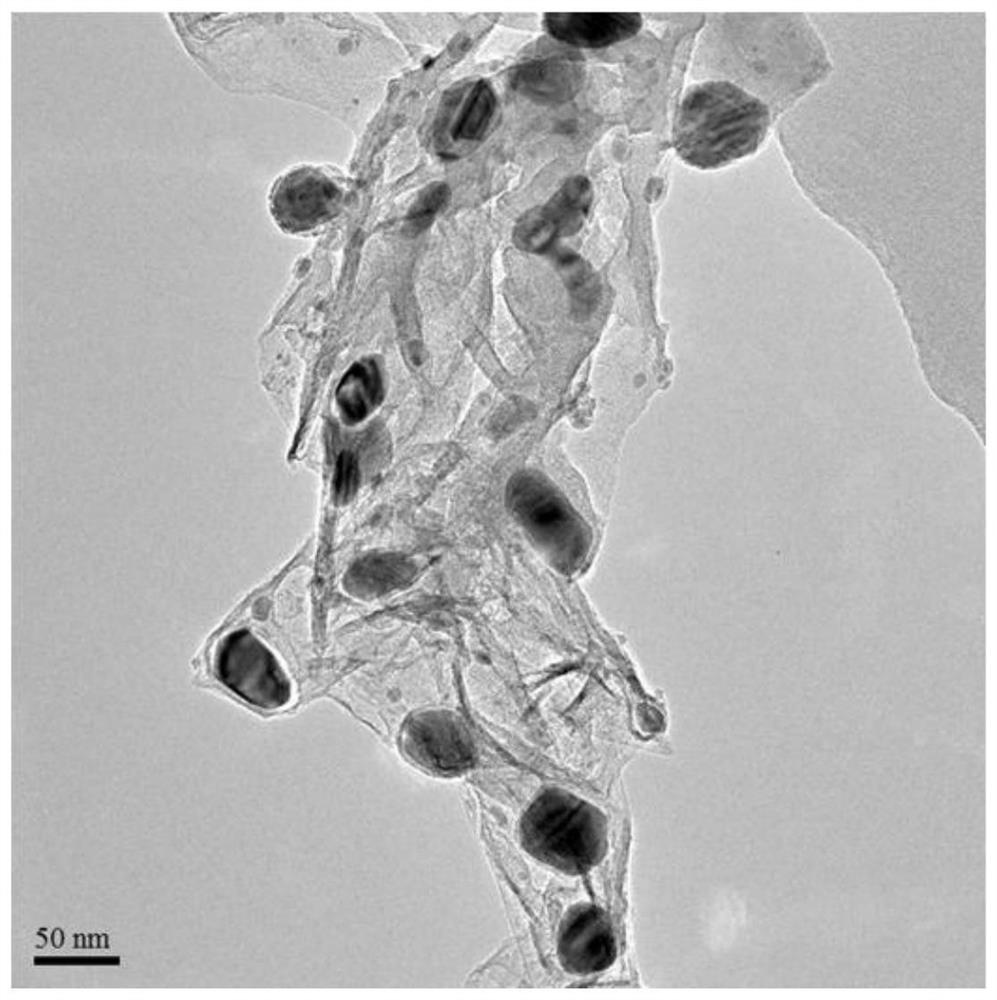

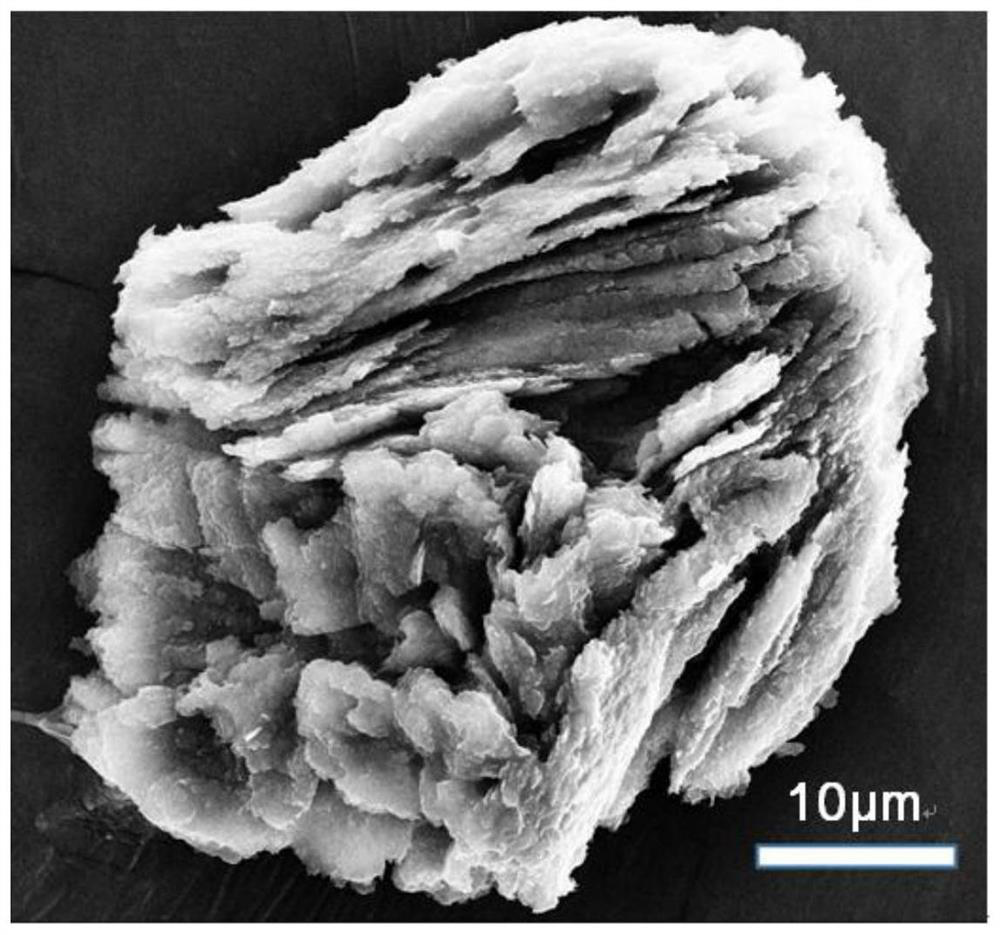

Ni3Fe-coated C nanocapsule-loaded multi-layer graphite lamellar structure with N doping defects

A technology of nanocapsules and graphite flakes, which is applied in the field of materials, can solve problems such as not involving wave absorption, and achieve the effects of low production cost, simple equipment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of loaded Ni by high temperature plasma arc evaporation technique 3 Fe@C nanocapsules and multilayer graphite sheet structure with N-doped defects:

[0051]In the plasma arc discharge evaporation process, the consumed anode target is a rod structure (φ6mm) pressed by 0.68at.% Fe powder, 2.72at.% Ni powder and 96.6at.% graphite powder, and the cathode The end of the graphite rod close to the anode is tapered, the taper angle is 30 degrees, and the distance between the graphite cathode and the anode target is 1.5mm. Vacuum chamber up to 5×10 -3 After Pa, 20ml of acetonitrile was introduced into the vacuum cavity. Turn on the DC power supply, adjust the voltage to 20-50V, plasma arc discharge occurs between the anode target and the cathode, and the arc discharge current is 100A. During the arc discharge process, adjust the working current and voltage to keep relatively stable, and the arc maintenance time is 80 minutes , prepared in the above atmosphere to s...

Embodiment 2

[0061] Preparation of loaded Ni by high temperature plasma arc evaporation technique 3 Fe@C nanocapsules and multilayer graphite sheet structure with N-doped defects:

[0062] In the plasma arc discharge evaporation process, the consumed anode target is a rod structure (φ8mm) pressed by 1.02at.% Fe powder, 2.38at.% Ni powder and 96.6at.% graphite powder, and the cathode The end of the graphite rod close to the anode is tapered, the taper angle is 30 degrees, and the distance between the graphite cathode and the anode target is 1.5 mm. Vacuum chamber up to 5×10 -3 After Pa, 20ml of acetonitrile was introduced into the vacuum cavity. Turn on the DC power supply, adjust the voltage to 20-40V, plasma arc discharge occurs between the anode target and the cathode, and the arc discharge current is 100A. During the arc discharge process, adjust the working current and voltage to keep relatively stable, and the arc maintenance time is 80 minutes , prepared in the above atmosphere to...

Embodiment 3

[0072] Preparation of loaded Ni by high temperature plasma arc evaporation technique 3 Fe@C nanocapsules and multilayer graphite sheet structure with N-doped defects:

[0073] In the plasma arc discharge evaporation process, the consumed anode target material is a rod structure (φ6mm) pressed by 2.69at.% Fe powder, 5.73at.% Ni powder and 91.58at.% graphite powder, and the cathode The end of the graphite rod close to the anode is tapered, the taper angle is 30 degrees, and the distance between the graphite cathode and the anode target is 1.2 mm. Vacuum chamber up to 5×10 -3 After Pa, 20ml of acetonitrile was introduced into the vacuum cavity. Turn on the DC power supply, adjust the voltage to 18-60V, plasma arc discharge occurs between the anode target and the cathode, and the arc discharge current is 150A. During the arc discharge process, adjust the working current and voltage to keep relatively stable, and the arc maintenance time is 15 minutes , prepared in the above atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com