A device for grinding raw materials in compound Yimu oral liquid and its application method

A technology of motherwort oral liquid and grinding device, applied in heating device, drying solid material, drying gas arrangement and other directions, can solve the problems of loss of motherwort, affecting grinding efficiency, low grinding efficiency, etc., to prevent the loss of nutrients, The effect of increasing the contact area and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

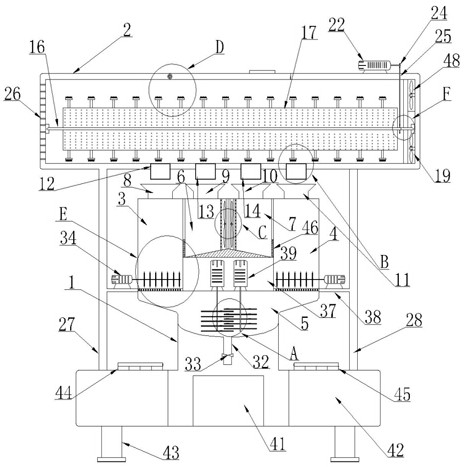

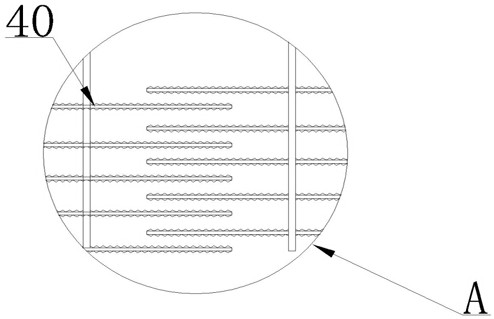

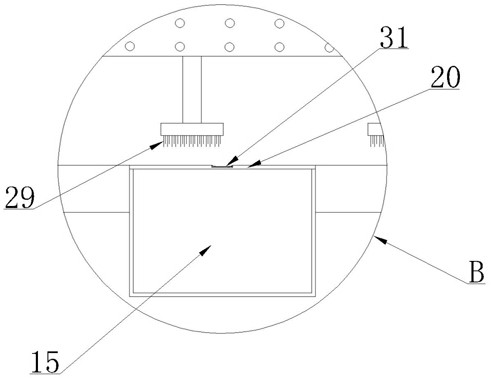

[0035] Such as Figure 1~7 As shown, a device for grinding raw materials in compound Yimu oral liquid, it includes a grinding device 1 and a primary drying heating device 2, the inside of the grinding device 1 is provided with a crushing chamber 1 3, a crushing chamber 2 4, Crushing chamber three 5, drying chamber one 6 and drying chamber two 7, the top of the grinding device 1 is provided with feed pipe one 8, feed pipe two 9, feed pipe three 10 and feed pipe Four 11, and the bottom of the primary drying heating device 2 is provided with the discharge pipe one 12, the discharge pipe one-to-one corresponding to the feed pipe one 8, the feed pipe two 9, the feed pipe three 10 and the feed pipe four 11. Material pipe two 13, discharge pipe three 14 and discharge pipe four 15, the inside of the first-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com