Continuous crystallization system and method for large-particle nickel sulfate

A crystallization system and nickel sulfate technology, applied in the field of large-particle nickel sulfate continuous crystallization system, can solve the problems of unstable product performance indicators, large product differences, low production efficiency, etc., and achieve good product quality stability, uniform particle size, Product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

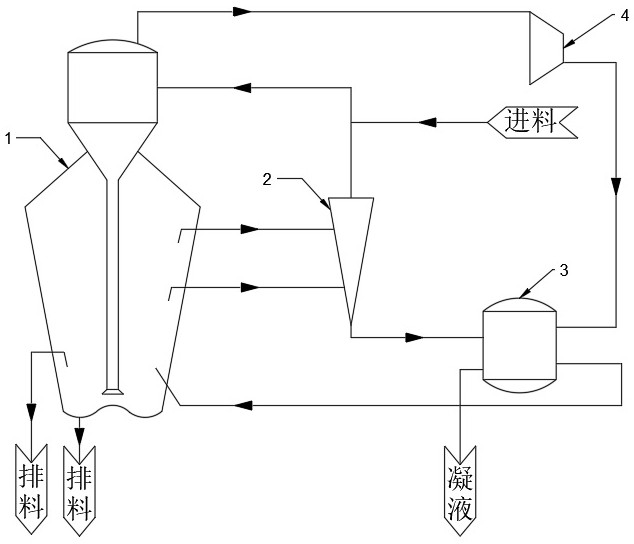

[0028]A continuous crystallization system of large-grained nickel sulfate comprises a main crystallizer, a classifier, a cooling unit, a dissolution unit and circulation equipment, the main crystallizer adopts an Oslo graded fluidized bed crystallizer, and the crystal bed area of the main crystallizer is Inverted conical structure, the upper diameter is twice the lower diameter, there are upper and lower sets of overflow circulation outlets on the top and middle upper part of the crystal bed area, and a discharge port is provided at the bottom of the crystal bed area, and the overflow circulation outlet passes through The circulation equipment is connected with the classifier, and the classifier is provided with two outlets, the upper outlet is connected with the inlet of the main crystallizer circulating clear liquid, the corresponding circulation pipeline is provided with a feed port, and is connected with the feed pump, and the lower outlet is connected with the dissolution...

Embodiment 2

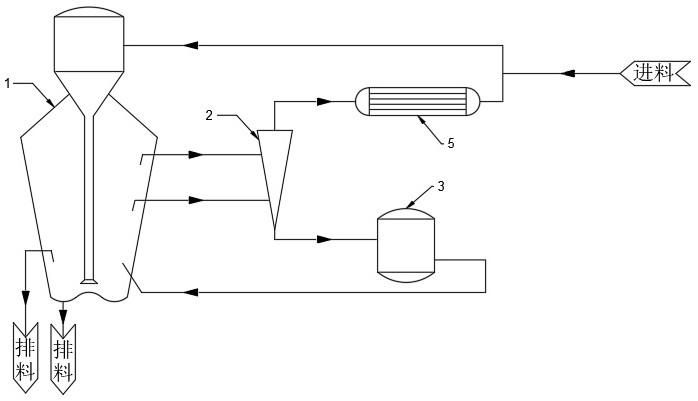

[0030] A continuous crystallization system for large particle nickel sulfate, comprising a main crystallizer, a classifier, a cooling unit, a dissolving unit and circulation equipment, the main crystallizer adopts a DTB graded fluidized bed crystallizer, and the crystal bed area of the main crystallizer is Inverted conical structure, the upper diameter is three times the lower diameter, there are two sets of overflow circulation outlets on the top and middle upper part of the crystal bed area, and a discharge port is provided at the bottom of the crystal bed area, and the overflow circulation outlet passes through The circulation equipment is connected with the classifier, and the classifier is provided with two outlets, the upper outlet is connected with the inlet of the main crystallizer circulating clear liquid, the corresponding circulation pipeline is provided with a feed port, and is connected with the feed pump, and the lower outlet is connected with the dissolution uni...

Embodiment 3

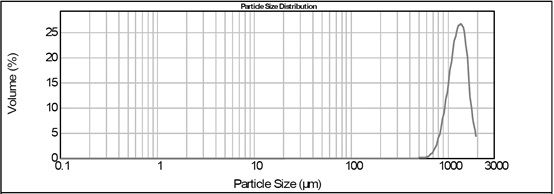

[0032] A method for continuous crystallization of large-grain nickel sulfate adopts the continuous crystallization system of large-grain nickel sulfate described in Example 1. The front-end nickel sulfate raw material solution is concentrated to a liquid phase density of 1600kg / m 3 After entering the crystallization system through the feed pipeline, the effective volume of the main crystallizer is 50m 3 , control the rising velocity of the liquid phase in the main crystallizer at 2-4cm / s. The temperature in the main crystallizer is 40°C, the liquid phase temperature in the dissolution tank is set to be 5°C higher than the liquid phase temperature in the main crystallizer, the liquid phase residence time is 300S, and the liquid phase concentration and crystal suspension amount in the dissolution tank are monitored as the main crystallizer The upper and lower sets of overflow circulation outlets of the classifier and the adjustment signals of the upper and lower outlet valves o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com