A method for continuous production of urea phosphate by vacuum evaporation and crystallization

A technology of vacuum evaporation and urea phosphate, which is applied in the field of urea derivatives, can solve the problems of extended production cycle, increased production cost, and decreased heat exchange efficiency, and achieve the effects of shortened crystallization time, improved device production capacity, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

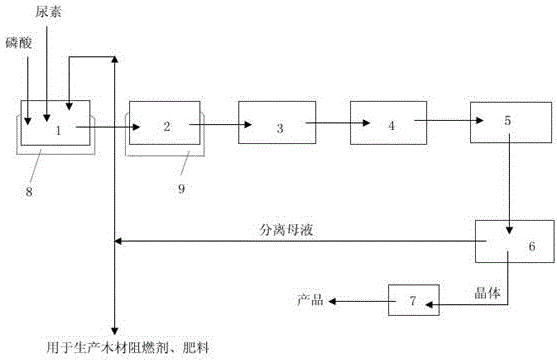

[0014] like figure 1 As shown, P 2 o 5 Phosphoric acid with a mass percentage concentration of 40% was added to a 1000L jacketed reactor at 400Kg / h, and the stirring was started at a speed of 50rpm. At the same time, urea was added at 176Kg / h, the temperature was raised to 80°C, and the reaction was carried out for 40 minutes. The specific gravity of the material was 1.4 Kg / L, the feed liquid overflows to the 1000L buffer tank, starts stirring at a speed of 50rpm, and cools down to 70°C through the jacket condensing medium of the buffer tank, enters the first-stage vacuum evaporative cooling crystallizer for crystallization, and the stirring speed is 20rpm, The vacuum degree is 0.06MPa, the material temperature drops to 58°C, and then enters the second-stage vacuum evaporative cooling crystallizer for crystallization, the stirring speed is 20rpm, the vacuum degree is 0.07MPa, the material temperature drops to 48°C, and finally enters the third-stage vacuum The evaporative co...

Embodiment 2

[0016] like figure 1 As shown, P 2 o 5 Phosphoric acid with a mass percentage concentration of 44% was added to a 1000L jacketed reactor at 400Kg / h, and the stirring was started at a speed of 50rpm. At the same time, urea was added at 178Kg / h, the temperature was raised to 85°C, and the reaction was carried out for 50 minutes. The specific gravity of the material was 1.43 Kg / L, the feed liquid overflows to the 1000L buffer tank, starts stirring at a speed of 50rpm, and cools down to 75°C through the jacketed condensing medium of the buffer tank, enters the first-stage vacuum evaporative cooling crystallizer for crystallization, and the stirring speed is 30rpm, The vacuum degree is 0.065MPa, the material temperature drops to 63°C, and then enters the second-stage vacuum evaporative cooling crystallizer for crystallization, the stirring speed is 30rpm, the vacuum degree is 0.075MPa, the material temperature drops to 53°C, and finally enters the third-stage vacuum The evaporati...

Embodiment 3

[0018] like figure 1 As shown, P 2 o 5 Phosphoric acid with a mass percentage concentration of 55% was added to a 1000L jacketed reactor at 400Kg / h, and the stirring was started at a speed of 55rpm. At the same time, urea was added at 204Kg / h, the temperature was raised to 85°C, and the reaction was carried out for 60 minutes. The specific gravity of the material was 1.53 Kg / L, the feed liquid overflows to the 1000L buffer tank, starts stirring at a speed of 55pm, and cools down to 75°C through the buffer tank jacket condensing medium, enters the first-stage vacuum evaporative cooling crystallizer for crystallization, and the stirring speed is 40rpm, The vacuum degree is 0.07MPa, the material temperature drops to 63°C, and then enters the second-stage vacuum evaporative cooling crystallizer for crystallization, the stirring speed is 40rpm, the vacuum degree is 0.08MPa, the material temperature drops to 53°C, and finally enters the third-stage vacuum The evaporative cooling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com