Absorbable intravascular stent and preparation method thereof

A vascular stent, the technology of the opposite direction, applied in the field of luminal stents, can solve the problem of uncontrollable degradation time of absorbable vascular stents, and achieve the effects of good blood vessel healing and repair, regulation of degradation rate, and delay of degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

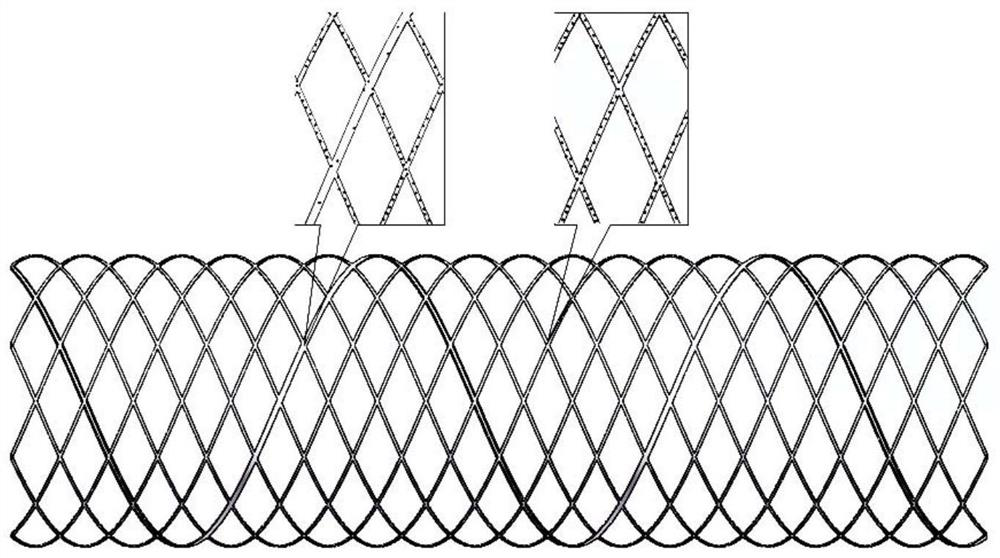

[0033] figure 1 Schematic diagram of braided vascular stent for titanium-infiltrated PPDO / PCL. Such as figure 1 As shown, an absorbable vascular stent of this embodiment is formed by interweaving core-spun yarns and titanium-infiltrated PPDO monofilaments, and the interweaving points of the core-spun yarns are fixed by welding. The core yarn of the core-spun yarn is a titanium-infiltrated PPDO monofilament, the sheath yarn is a PCL multifilament, and the sheath yarn completely covers the core yarn. The titanium-infiltrated PPDO monofilament includes a titanium dioxide film covering the surface of the PPDO monofilament substrate.

[0034] Preferably, the thickness of the titanium dioxide film is 10 -8 m~3×10 -8 m.

[0035] Preferably, the titanium dioxide thin film is coated layer by layer on the surface of the PPDO monofilament substrate in the form of a monoatomic film.

Embodiment 2

[0037] A method for an absorbable vascular stent that can regulate the degradation rate, the specific steps are as follows:

[0038] (1) First heat the ALD chamber to 70°C, then put the PPDO monofilament into the ALD reactor for TiO2 deposition, and deposit 400 deposition cycles to obtain titanium-infiltrated PPDO monofilament;

[0039]The process of a single deposition cycle is as follows: keep 1h under the pressure of 0.1Torr, use high-purity nitrogen (99.999%) and ordinary nitrogen (99.9%) as the carrier gas and purge gas of the ALD process, titanium isopropoxide and H2O As the precursor source, it enters the ALD reactor through alternate pulses of the carrier gas; when the carrier gas is alternately pulsed, the pulse time of titanium isopropoxide and H2O is 1s; after the pulse, each precursor is kept in the chamber for 40s to make PPDO The monofilament substrate is fully exposed to the precursor vapor, and then the reaction chamber is purged with ordinary nitrogen at a flo...

Embodiment 3

[0046] A method for an absorbable vascular stent that can regulate the degradation rate, the specific steps are as follows:

[0047] (1) First heat the ALD chamber to 80°C, then put the PPDO monofilament into the ALD reactor for TiO2 deposition, and deposit 200 deposition cycles to obtain titanium-infiltrated PPDO monofilament;

[0048] The process of a single deposition cycle is as follows: keep 1h under the pressure of 0.1Torr, use high-purity nitrogen (99.999%) and ordinary nitrogen (99.9%) as the carrier gas and purge gas of the ALD process, titanium isopropoxide and H2O As the precursor source, it enters the ALD reactor through alternate pulses of the carrier gas; when the carrier gas is alternately pulsed, the pulse time of titanium isopropoxide and H2O is 1s; after the pulse, each precursor is kept in the chamber for 40s to make PPDO The monofilament substrate is fully exposed to the precursor vapor, and then the reaction chamber is purged with ordinary nitrogen at a fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com