A high-temperature steam sterilization and disinfection device for the production of antler mushrooms

A sterilizing device and high-temperature steam technology, applied in steam boilers, steam generation, steam boiler accessories, etc., can solve the problems of waste of water resources, heat energy and gas pressure, inconvenient control of steam box gas pressure, poor sterilization and disinfection effects, etc. , to reduce the loss of heat energy, improve the effect and efficiency of sterilization and disinfection, and prevent the waste of heat energy and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

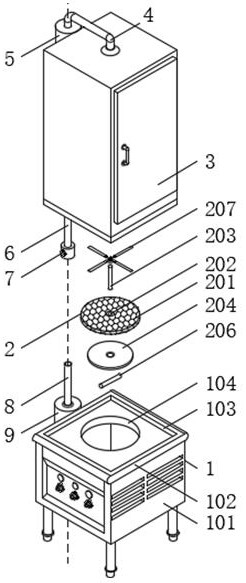

[0037] The following is combined with the attached Figure 1-5 The present invention will be further elaborated.

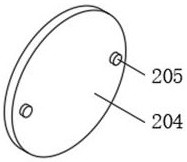

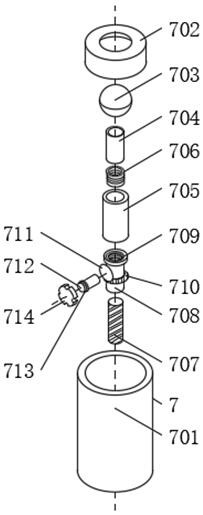

[0038] See Figure 1-4 , the present invention provides a technical solution: a high-temperature steam sterilization and disinfection device for deer antler mushroom production, comprising a steam generation component 1, the inner side of the top of the steam generation assembly 1 is provided with a sealed high-temperature steaming box 3, and the steam generation assembly 1 corresponding to the position of the sealed high-temperature steaming box 3 is provided with a mixed-flow component 2, the top of the sealed high-temperature steaming box 3 is connected to the top of the steam filter 5 through the first return pipe 4, the steam filter 5 and the opposite surface of the sealed high-temperature steam box 3 are fixedly connected, The bottom of the steam filter 5 is connected to the top of the pressure control assembly 7 through the second reflow pipe 6, the bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com