Engine performance parameter correction method based on in-orbit data

A technology of parameter correction and track-controlled engine, applied in the direction of electrical digital data processing, special data processing application, computer-aided design, etc., can solve the problems of ground heat scale accuracy to be improved, loss, system error, etc., to improve prediction accuracy and Orbit change efficiency, wide application value and promotion prospects, and the effect of improving estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described below in conjunction with the accompanying drawings.

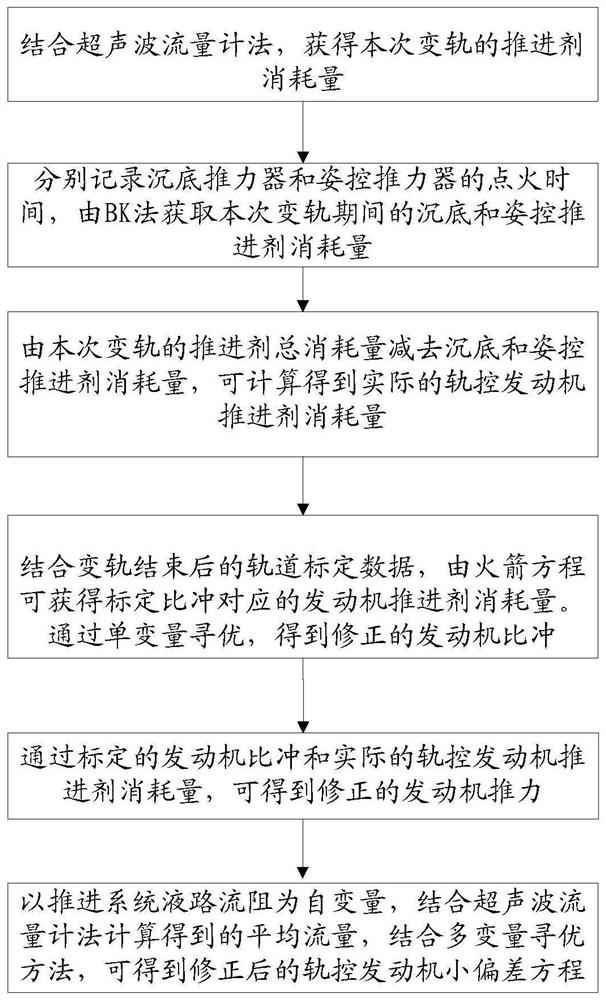

[0043] Such as figure 1 As shown, a method for revising engine performance parameters based on on-orbit data includes the following steps:

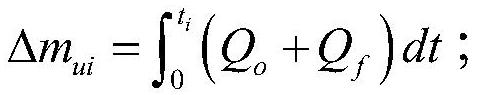

[0044](1) Before each orbit change of the satellite, turn on the ultrasonic flowmeter configured on the satellite to measure the propellant flow during the working process of the engine. After the orbit control engine is ignited, turn off the ultrasonic flowmeter and stop the flow measurement; during each orbit change, Integrate the output of the ultrasonic flowmeter to obtain the propellant consumption Δm during the orbit change process ui ;

[0045]

[0046] Among them, Q o , Q f Respectively, the output flow rate of the ultrasonic flowmeter corresponding to the downstream of the oxidant and combustion agent storage tanks, t i is the time of the i-th orbital maneuver; i is a positive integer;

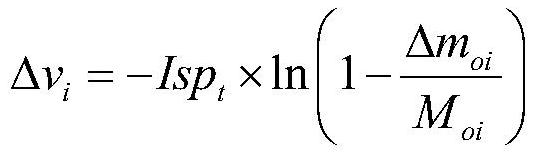

[0047] (2) Record the ignition ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com