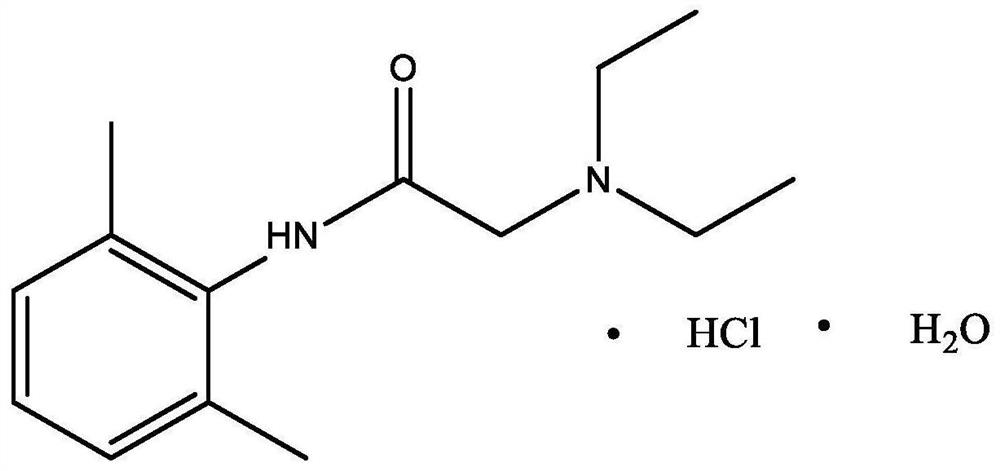

HPLC detection method for degradation impurities in lidocaine hydrochloride and preparation thereof

A technology of lidocaine hydrochloride and a detection method, which is applied in the field of pharmaceutical preparation and detection, can solve problems such as uncontrolled degradation of impurities, and achieve the effects of high sensitivity, strong specificity and good separation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

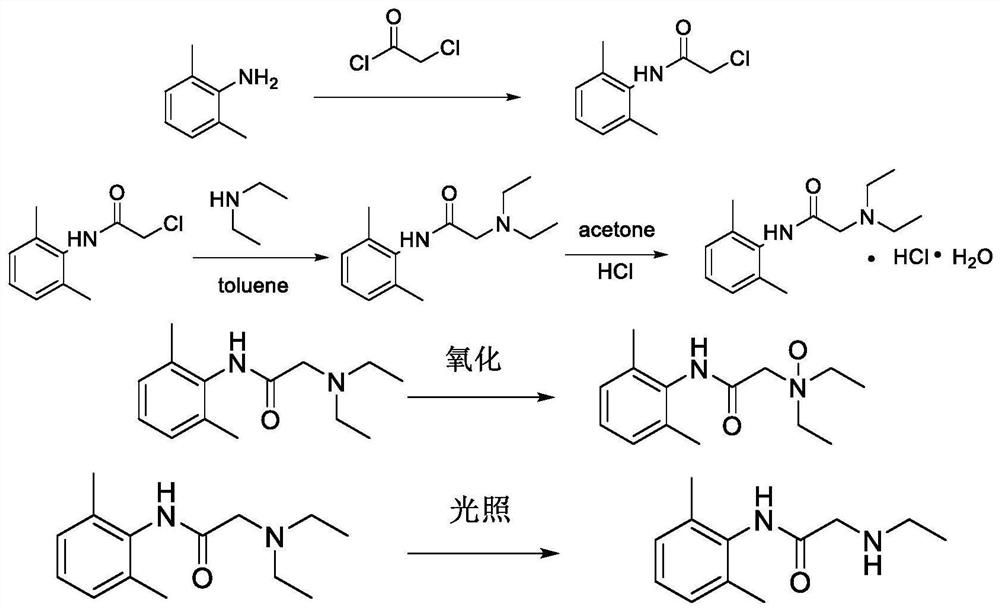

Problems solved by technology

Method used

Image

Examples

Embodiment 1

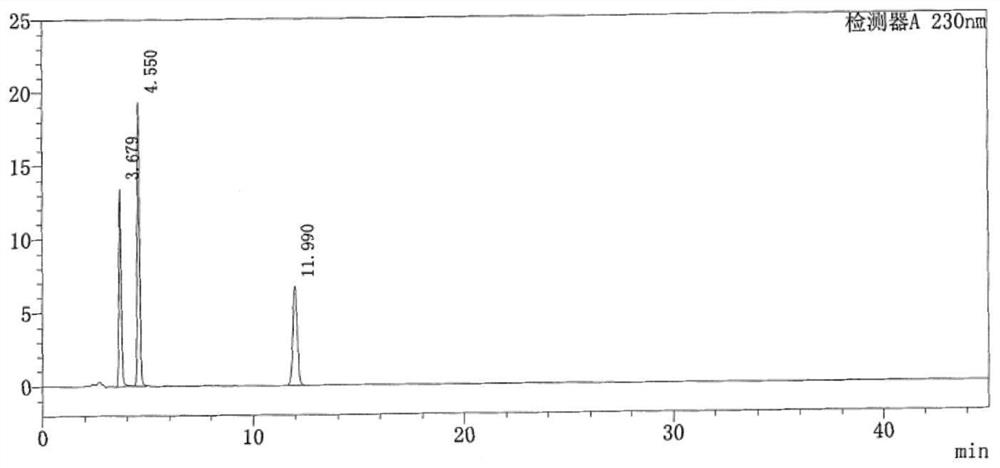

[0030] The instruments and setting conditions adopted in this embodiment are as follows:

[0031] High performance liquid chromatography: Shimadzu LC-20AT;

[0032] Chromatographic column: Thermo Hypersil GOLD Dim.(mm) C18, 250mm×4.6mm, 5μm;

[0033] Flow rate of mobile phase: 1mL / min;

[0034] Detection wavelength: 230nm;

[0035] Column temperature: 30°C;

[0036] Injection volume: 20uL;

[0037] Wherein the mobile phase: Phosphate buffer and acetonitrile (adjust the pH value to 8.0 with phosphoric acid) is configured as the mobile phase according to the mass and number ratio of 55:45, wherein the concentration of 0.01mol / L phosphate buffer is prepared in the following way: Take Dilute 1.3ml of lmol / L sodium dihydrogen phosphate solution and 32.5ml of 0.5mol / L disodium hydrogen phosphate solution to 1000ml with water and shake well.

[0038] Experimental steps:

[0039] Step 1: Solution preparation

[0040] System suitability solution: Take this product and impurities...

Embodiment 2

[0046] The instruments and setting conditions adopted in this embodiment are as follows

[0047] High performance liquid chromatography: Shimadzu LC-20AT;

[0048] Chromatographic column: Thermo Hypersil GOLD Dim.(mm) C18, 250mm×4.6mm, 5μm;

[0049] Flow rate of mobile phase: 1mL / min;

[0050] Detection wavelength: 230nm;

[0051] Column temperature: 30°C;

[0052] Injection volume: 20uL;

[0053] Wherein the mobile phase: Phosphate buffer and acetonitrile (adjust the pH value to 8.0 with phosphoric acid) is configured as the mobile phase according to the mass and number ratio of 57:43, wherein the concentration is 0.01mol / L The phosphate buffer is prepared in the following way: Take Dilute 1.3ml of lmol / L sodium dihydrogen phosphate solution and 32.5ml of 0.5mol / L disodium hydrogen phosphate solution to 1000ml with water and shake well.

[0054] Experimental steps:

[0055] Step 1: Solution preparation

[0056] System suitability solution: Take this product and impurit...

Embodiment 3

[0062] The instrument and setting conditions adopted in this embodiment:

[0063] High performance liquid chromatography: Shimadzu LC-20AT

[0064] Chromatographic column: Thermo Hypersil GOLD Dim.(mm) C18, 250mm×4.6mm, 5μm;

[0065] Flow rate of mobile phase: 1mL / min;

[0066] Detection wavelength: 230nm;

[0067] Column temperature: 30°C;

[0068] Injection volume: 20uL;

[0069] Wherein the mobile phase: Phosphate buffer and acetonitrile (adjust the pH value to 8.0 with phosphoric acid) is configured as the mobile phase according to the mass and number ratio of 59:41, wherein the concentration is 0.01mol / L The phosphate buffer is prepared in the following way: Take Dilute 1.3ml of lmol / L sodium dihydrogen phosphate solution and 32.5ml of 0.5mol / L disodium hydrogen phosphate solution to 1000ml with water and shake well.

[0070] Experimental steps:

[0071] Step 1: Solution preparation

[0072] System suitability solution: Take this product and impurities 2-(diethylbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com