Prefabricated assembled UHPC-corrugated steel web combined box girder bridge and construction method

A corrugated steel web, prefabricated assembly technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of restricting popularization and application, reducing structural durability, and difficulty in resisting tensile stress, etc., to achieve simple structural design, Avoid cracking and buckling, improve the effect of the main span span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

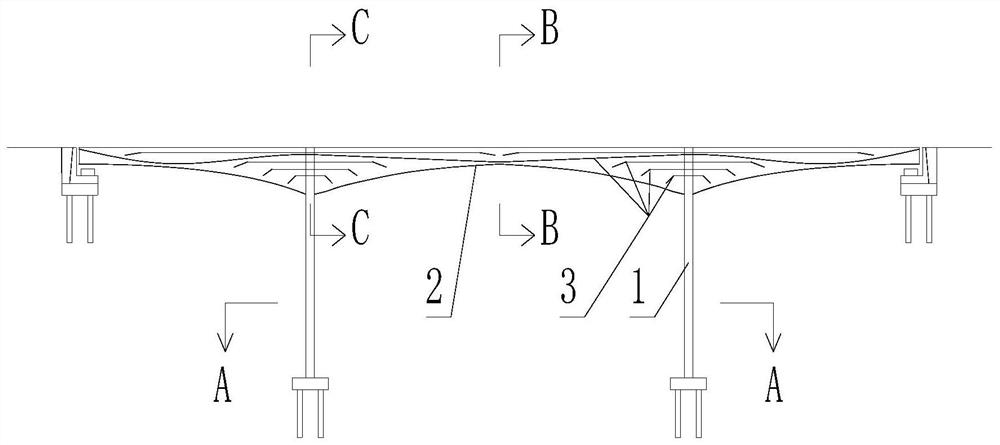

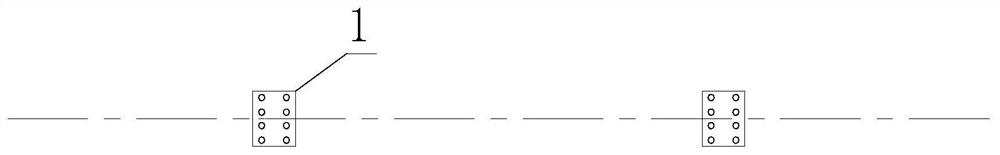

[0044] see Figure 1 ~ Figure 4 , the prefabricated assembled UHPC-corrugated steel web composite box girder bridge provided in this embodiment, the span layout of the continuous box girder bridge is 300m+450m+300m, and the continuous steel structure bridge design is adopted.

[0045] The continuous box girder bridge provided in this embodiment includes a bridge pier 1 and a UHPC-corrugated steel web composite box girder, and the UHPC-corrugated steel web composite box girder adopts an external and internal prestressing system in the longitudinal direction of the bridge.

[0046]The prefabricated assembled UHPC-corrugated steel web composite box girder bridge provided in this embodiment includes a bridge pier 1 and a UHPC-corrugated steel web composite box girder placed on the bridge pier 1 and connected to the bridge pier 1; The composite box girder is assembled sequentially by a plurality of UHPC-corrugated steel web composite box girder segments 2; the UHPC-corrugated steel...

Embodiment 2

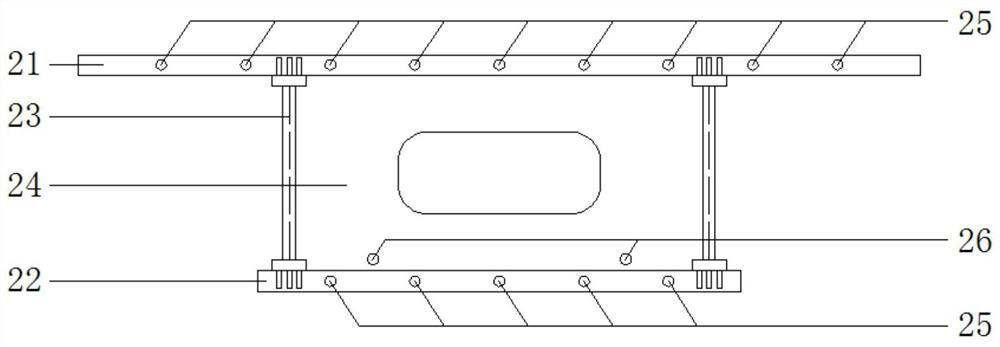

[0068] see Figure 5 ~ Figure 8 In the prefabricated assembled UHPC-corrugated steel web composite box girder bridge of the present invention provided in this embodiment, the span of the continuous box girder bridge is 270m+400m+270m, and the continuous girder bridge design is adopted.

[0069] The continuous box girder bridge includes pier 1 and a UHPC-corrugated steel web composite box girder, and the UHPC-corrugated steel web composite box girder adopts an external and internal prestressing system in the longitudinal direction of the bridge.

[0070] The prefabricated assembled UHPC-corrugated steel web composite box girder bridge provided in this embodiment includes a bridge pier 1 and a UHPC-corrugated steel web composite box girder placed on the bridge pier 1 and connected to the bridge pier 1; The composite box girder is assembled sequentially by a plurality of UHPC-corrugated steel web composite box girder segments 2; the UHPC-corrugated steel web composite box girder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com