A color-fixing treatment equipment for anti-ultraviolet fabric based on padding process

An anti-ultraviolet and color treatment technology, applied in the processing of textile materials, equipment configuration for processing textile materials, liquid/gas/vapor textile material processing, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

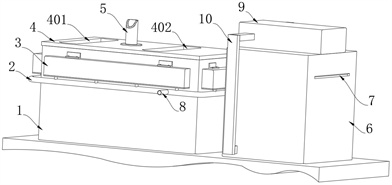

[0032] Embodiment 1: refer to Figure 1-8 , a kind of color-fixing treatment equipment for anti-ultraviolet fabrics based on the padding process, comprising a padding box 1 and a color-fixing box 6, four collection boxes 3 are symmetrically installed on the side wall of the padding box 1, and the A plurality of communication ports 12 are provided on the side wall of the padding box 1, and the communication ports 12 are respectively connected in sealing communication with four miscellaneous boxes 3, and the bottom of each said miscellaneous box 3 is sealed with a bottom plate 25, each The base plate 25 is provided with a miscellaneous platform 26, and the two ends of the miscellaneous platform 26 are respectively sealed against the inner wall of the corresponding miscellaneous box 3, and the position of the communication port 12 is close to the bottom of the miscellaneous platform 26. The outer circumference of the tank 1 is provided with a liquid return pipe 2, and there are a...

Embodiment 2

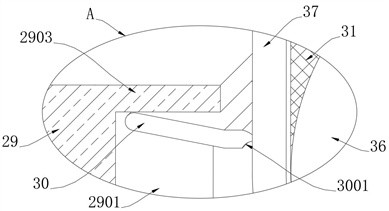

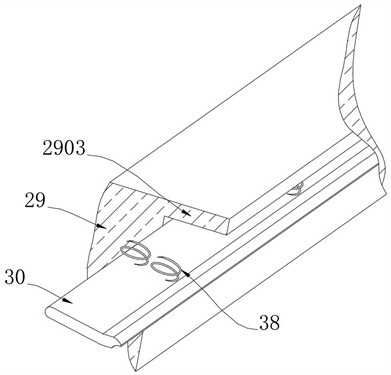

[0047] Embodiment 2: refer to Figure 9-11 The difference between this embodiment and Embodiment 1 is that: the upper side of the sinker 2901 is integrally formed with two ribs 2903, and the two ribs 2903 are slidingly connected with the flexible filter screen 31, each of which Scrapers 30 are movably arranged below the ribs 2903 , and multiple groups of coil springs 38 are connected between the corresponding scrapers 30 and the ribs 2903 .

[0048] In this embodiment, each of the scrapers 30 is provided with a hook-shaped groove 3001 with an opening downward near the end of the flexible filter screen 31, and the hook-shaped groove 3001 is more convenient for cleaning the flexible filter screen 31. The plates 30 are all oriented obliquely to the axial position of the tensioning roller 36 located below.

[0049] In this embodiment, a pressure sensor 39 and a signal transmitter 40 are provided at the bottom of the sinker 2901 , and the pressure sensor 39 is located directly bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com