Ultrahigh-strength precipitation strengthening steel and preparation process and application thereof

A technology of precipitation strengthening and preparation process, applied in the field of steel production, can solve the problems of heavy tank body, poor wear resistance and corrosion resistance, cracking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

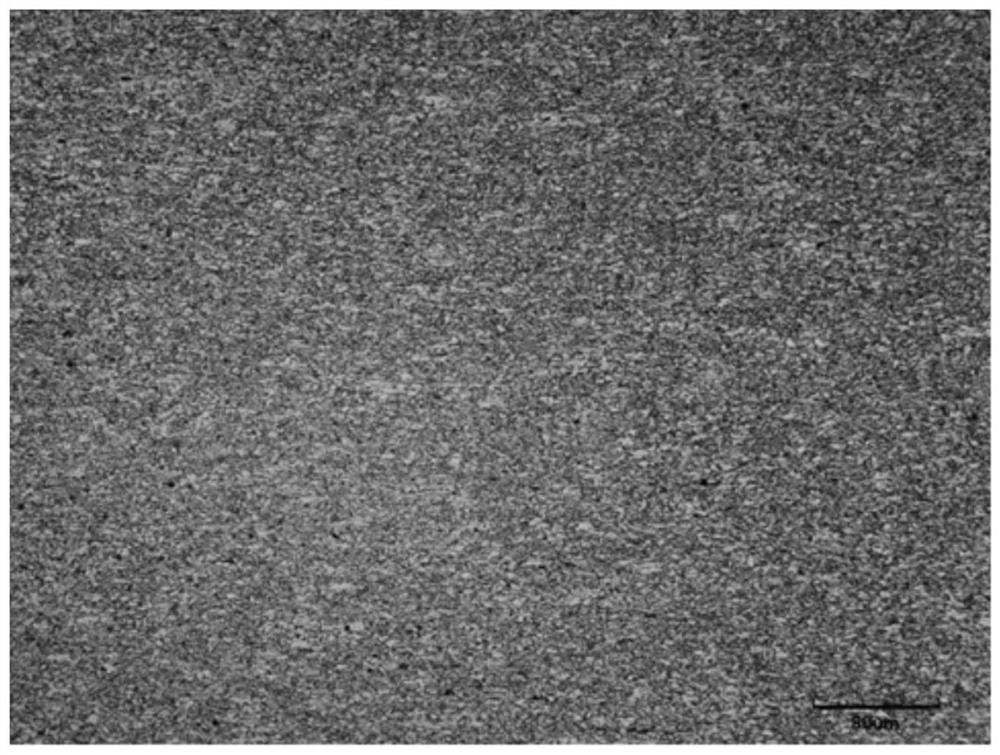

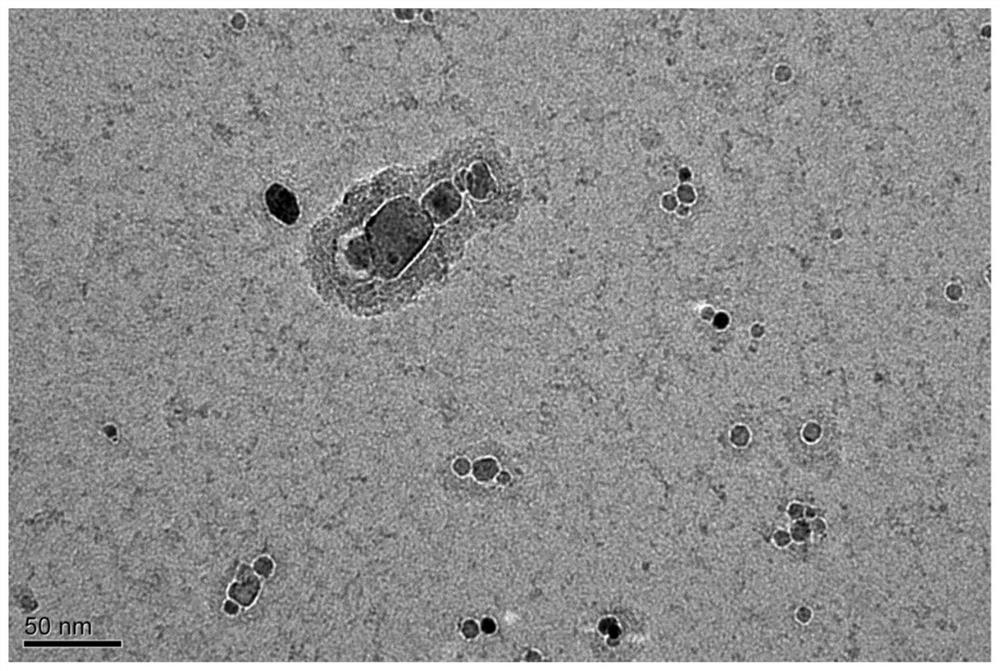

Image

Examples

Embodiment

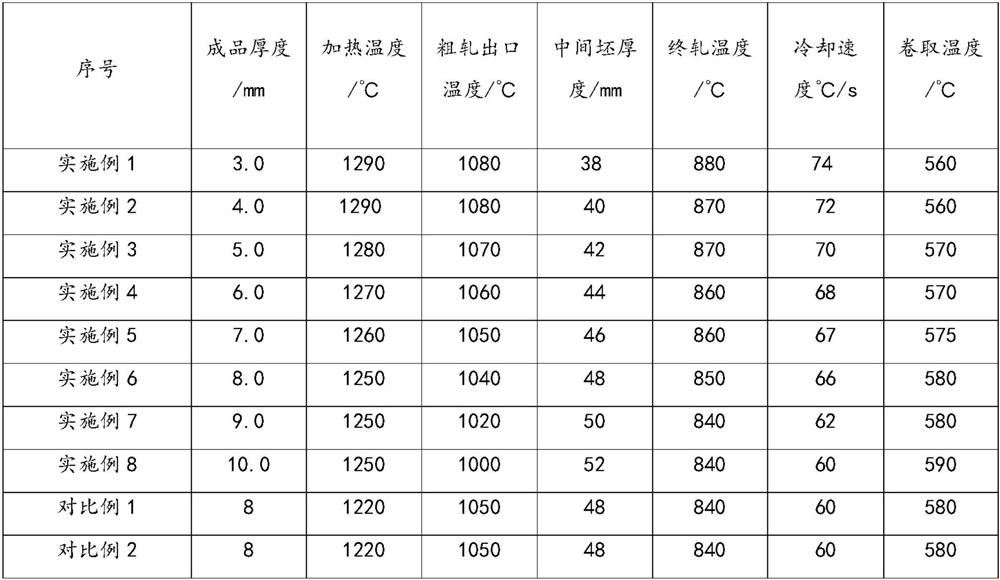

[0084] The present invention provides 8 embodiments and 2 comparative examples.

[0085] The chemical composition of a steel for an ultra-high-strength stirring tank is: C: 0.17%-0.22%; Si: 0.35%-0.55%; Mn: 1.70%-2.00%; Alt: 0.015-0.060%; P: ≤ 0.015%; S: ≤ 0.004%; Cr: 0.30% ~ 0.60%; Ti: 0.18% ~ 0.26%, B: 0.0007-0.0018%, Sn: 0.035 ~ 0.055%, the rest is iron and unavoidable impurities.

[0086] The concrete smelting chemical composition of embodiment 1-8 and comparative example 1,2 is shown in Table 1:

[0087] The slab chemical composition (%) of table 1 embodiment 1-8 and comparative example 1,2

[0088] serial number C Si mn P S Alt Ti Cr B sn Example 1 0.18 0.40 1.83 0.010 0.002 0.032 0.19 0.52 0.0009 0.040 Example 2 0.19 0.42 1.96 0.009 0.003 0.038 0.20 0.45 0.0012 0.035 Example 3 0.20 0.55 1.70 0.011 0.002 0.041 0.25 0.30 0.0017 0.042 Example 4 0.22 0.48 1.79 0.012 0.003 0.035 0.18 0.42 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com