Heat treatment device of high-chromium wear-resistant ball for mine

A technology of heat treatment device and wear-resistant ball, applied in heat treatment furnace, heat treatment equipment, quenching device, etc., can solve the problems of wear-resistant ball tensile plasticity, poor service life of wear resistance, uneven heating, over-burning of heating surface, etc. , to achieve the effects of reducing scrap rate, improving heat treatment efficiency, and avoiding overburning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

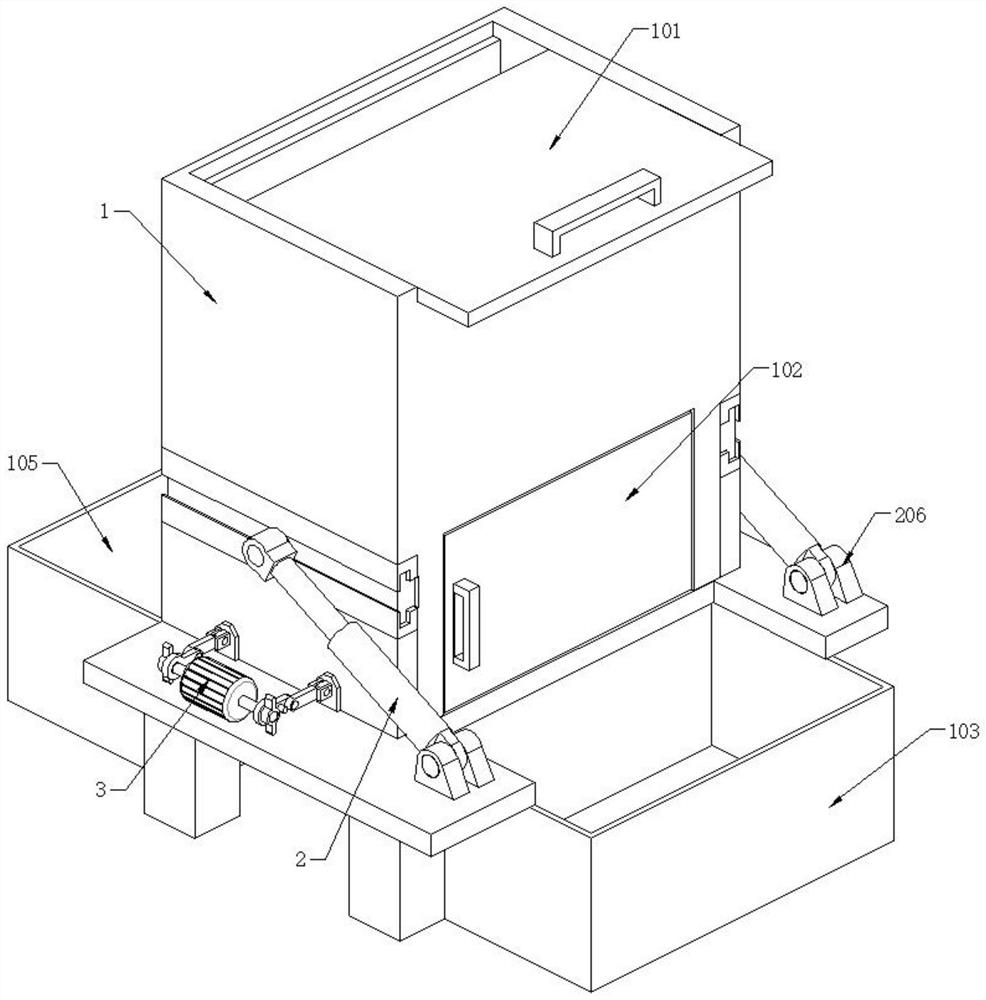

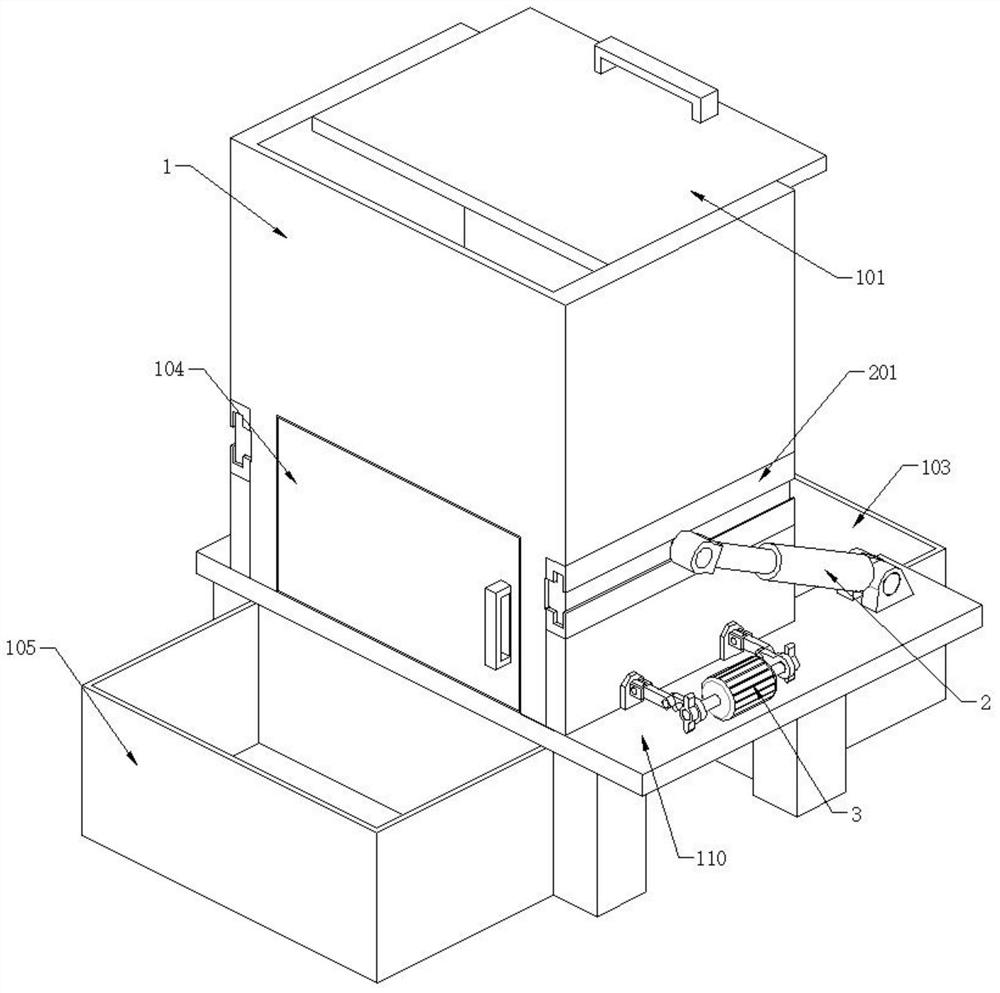

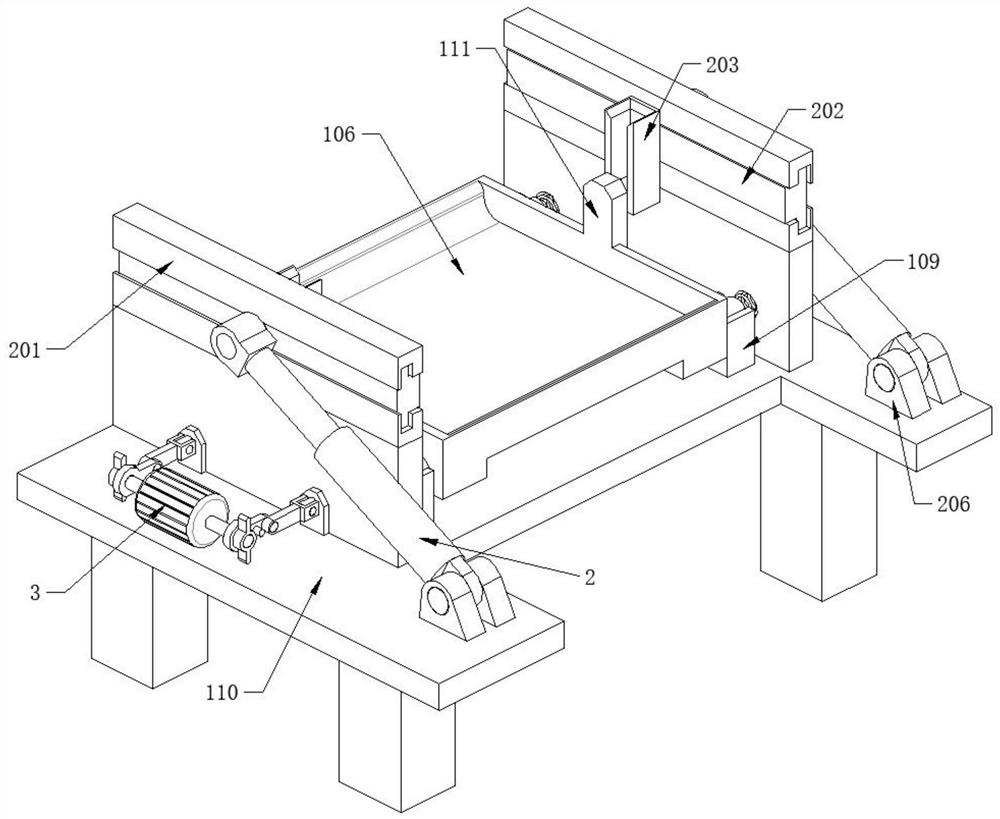

[0033] refer to Figure 1-8 , a high chromium wear-resistant ball heat treatment device for mines, comprising a base 110 and a heating furnace body 1, the heating furnace body 1 is connected to the top of the base 110, the top wall of the heating furnace body 1 is provided with a material inlet 101, and the inside of the heating furnace body 1 Connected with a tray 106, the tray 106 matches the feed port 101, the side wall of the tray 106 is connected with a rotating rod 108, the top wall of the base 110 is provided with a shaking mechanism and a turret 109, the shaking mechanism matches the tray 106, and the rotating rod 108 cooperates with the turret 109, the side wall of the heating furnace body 1 is provided with a discharge assembly, the side wall of the heating furnace body 1 is provided with a first discharge port 102 and a second discharge port 104, the first discharge port 102 and the second discharge port The two discharge outlets 104 are all matched with the tray 10...

Embodiment 2

[0040] refer to Figure 1-8 , a high chromium wear-resistant ball heat treatment device for mines, comprising a base 110 and a heating furnace body 1, the heating furnace body 1 is connected to the top of the base 110, the top wall of the heating furnace body 1 is provided with a material inlet 101, and the inside of the heating furnace body 1 Connected with a tray 106, the tray 106 matches the feed port 101, the side wall of the tray 106 is connected with a rotating rod 108, the top wall of the base 110 is provided with a shaking mechanism and a turret 109, the shaking mechanism matches the tray 106, and the rotating rod 108 cooperates with the turret 109, the side wall of the heating furnace body 1 is provided with a discharge assembly, the side wall of the heating furnace body 1 is provided with a first discharge port 102 and a second discharge port 104, the first discharge port 102 and the second discharge port The two discharge outlets 104 are all matched with the tray 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com