Insulating resin composite material, high-voltage insulating sleeve and preparation method and application of high-voltage insulating sleeve

A technology of insulating resin and composite material, which can be used in insulators, insulators, electrical components, etc., and can solve the problems of increased dielectric loss and low mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the insulating resin compound provided by the present invention comprises uniformly mixing component A, component B and optional component C to obtain the insulating resin compound. Wherein, the component A, component B and component C have been described above and will not be repeated here.

[0033] In a preferred embodiment, when the insulating resin compound does not contain component C, the preparation method of the insulating resin compound comprises the following steps:

[0034] S11. Preparation of component A and component B: bisphenol A epoxy resin, N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane and 3,4 -Epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate was heated to 50-80°C, stirred and mixed evenly under vacuum to obtain component A; phthalic anhydride, methyltetrahydrophthalic anhydride, methyl Hexahydrophthalic anhydride and benzyltriethylammonium chloride were heated to 50-80°C, stirred and mixed evenly under vacuum to...

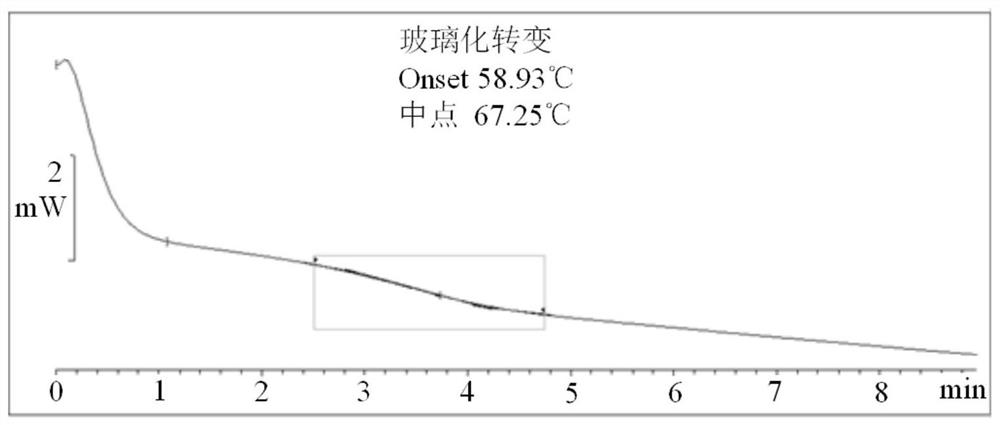

Embodiment 1

[0049] This embodiment is used to illustrate the insulating resin composite provided by the present invention and its preparation method.

[0050] S11, 60 parts by weight of bisphenol A epoxy resin, 20 parts by weight of N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane and 20 parts by weight of 3 , 4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate was heated to 50°C, stirred and mixed under vacuum for 40 minutes to obtain component A; 30 parts by weight of phthalic anhydride, 10 parts by weight of Methyl tetrahydrophthalic anhydride, 60 parts by weight of methyl hexahydrophthalic anhydride and 0.1 part by weight of benzyltriethylammonium chloride were heated to 50°C, stirred and mixed under vacuum for 30 minutes to obtain component B;

[0051] S12. Stir component A with the rotational speed controlled at 800r / min, add component B while stirring, continue stirring and mixing for 40 minutes after component B is added, and obtain an insulating resin composite material...

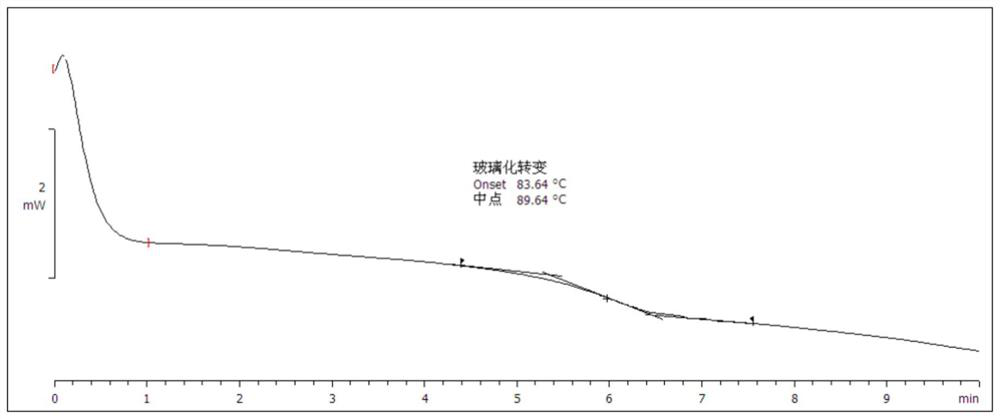

Embodiment 2

[0053] This embodiment is used to illustrate the insulating resin composite provided by the present invention and its preparation method.

[0054] S11, 90 parts by weight of bisphenol A epoxy resin, 5 parts by weight of N,N,N',N'-tetraepoxypropyl-4,4'-diaminodiphenylmethane and 5 parts by weight of 3 , 4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate was heated to 80°C, stirred and mixed under vacuum for 40min to obtain component A; 10 parts by weight of phthalic anhydride, 10 parts by weight of Methyltetrahydrophthalic anhydride, 80 parts by weight of methylhexahydrophthalic anhydride and 0.5 parts by weight of benzyltriethylammonium chloride were heated to 80°C, stirred and mixed under vacuum for 30 minutes to obtain component B;

[0055] S12. Stir component A with the rotating speed controlled at 800r / min, add component B while stirring, continue stirring and mixing for 40 minutes after component B is added, and obtain an insulating resin compound, denoted as JF-2, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com