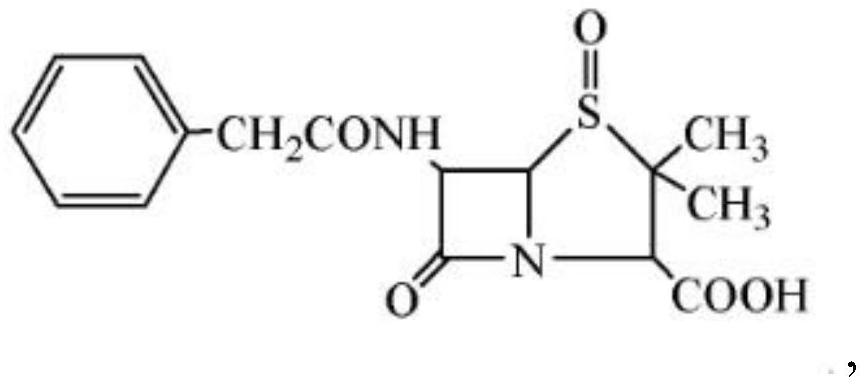

Industrial production method for preparing penicillin sulfoxide by continuously oxidizing penicillin

A penicillin sulfoxide and production method technology, applied in the field of medicine and chemical industry, can solve the problems of reaction mass transfer, low heat transfer efficiency affecting reaction temperature, reaction time, poor quality of reaction liquid, low reaction yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] ① Preparation of reference solution

[0029] Accurately weigh about 40 mg of the oxide reference substance, place it in a 50 mL volumetric flask, add mobile phase to dilute to the mark, and shake well.

[0030] ② Preparation of the test solution

[0031] Accurately weigh (or measure) about 1.0g (or 1mL) of the test product in a 50mL volumetric flask, dilute to the mark with mobile phase, and shake well.

[0032] ③Determination: Detection by high performance liquid chromatography, calculated by external standard method.

Embodiment 1

[0033] The oxidation of embodiment 1 penicillin industrial salt

[0034] Dissolve 50 grams of penicillin potassium salt in 1000 milliliters of water to form a penicillin potassium salt solution (penicillin potency 79618u / ml), cool down to 10°C, and cool down to 10°C with 40 milliliters of peracetic acid with a volume concentration of 30%. The two pass through the microreactor at the flow rate of 25ml / min and 1ml / min respectively, and the temperature is controlled at 10-15°C. The content of penicillin sulfoxide in the detected reaction solution is 43.05mg / ml, and the oxidation yield is 98.05%.

Embodiment 2

[0035] The oxidation of embodiment 2 penicillin back extract (RB)

[0036] Cool 1000 ml of penicillin back-extraction (penicillin titer 199613u / ml) to 10°C, and cool 50 ml of hydrogen peroxide with a volume concentration of 27.5% to 5°C. The microreactor controls the temperature at 5-10° C., detects that the content of penicillin sulfoxide in the reaction solution is 110.52 mg / ml, and the oxidation yield is 98.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com